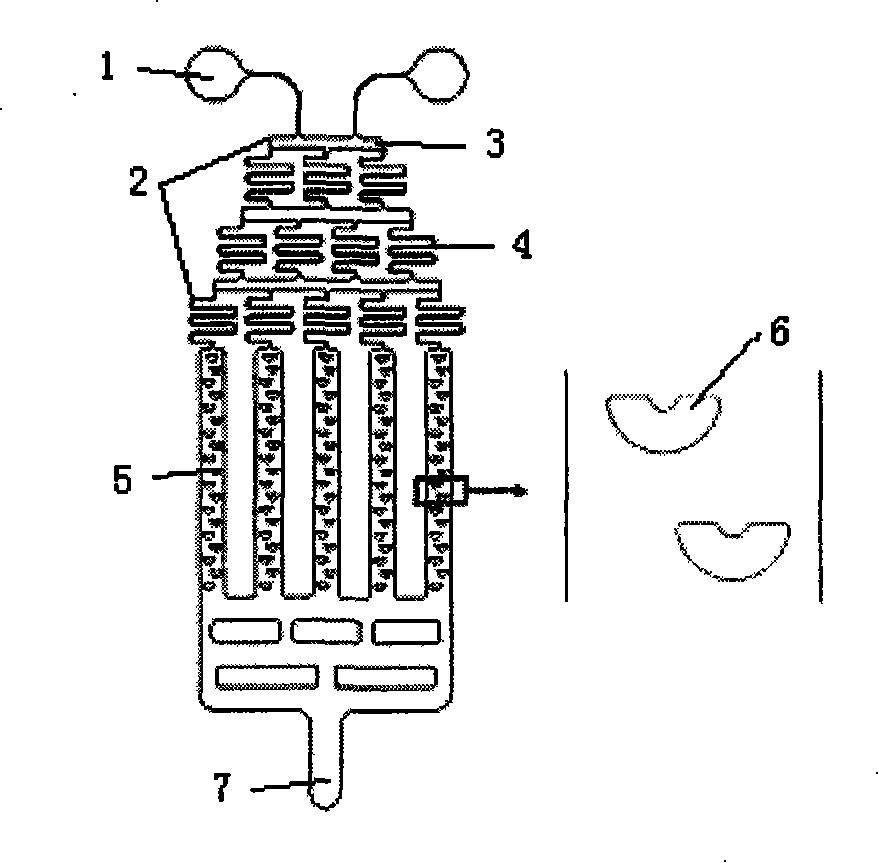

Micro-fluid concentration gradient cell culture chip and its preparation method and application

A technology of cell culture and concentration gradient, which is applied to tissue cell/virus culture devices, biochemical equipment and methods, applications, etc., can solve the problems of large consumption of culture medium, and achieve convenient operation, small volume, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Concentration Gradient Experiment of Rhodamine Solution

[0021] 1. Take the prepared PDMS cell culture chip, fill it with distilled water, and vacuum for 15 minutes;

[0022] 2. Put two microsyringes respectively containing rhodamine dye (0.048mg / l) and sodium carbonate-sodium bicarbonate buffer (0.1M, pH9.4) into the microsyringe pump and check;

[0023] 3. Remove the air bubbles in the microinjector and the connecting catheter at a sample pushing rate of 10 μl / min, and keep the sample pushing rate of the two microsyringes consistent;

[0024] 4. The microinjectors are respectively connected to the sample inlet of the PDMS chip through the connecting catheter, the left sample port is connected to the rhodamine fluorescent dye, and the right sample port is connected to the sodium carbonate-sodium bicarbonate buffer;

[0025] 5. Adjust the micro-injection pump to inject samples at a sample pushing rate of 1 μl / min. Solutions containing different components enter the ch...

Embodiment 2

[0029] Culture of mouse embryonic fibroblasts (3T3 cells) on a chip

[0030] 1. Fill the pipeline of the PDMS chip with 75% ethanol and place it for 2 hours;

[0031] 2. Take out, perfuse with PBS solution, remove ethanol. The chip is placed in a clean table and irradiated with ultraviolet light for 4 hours;

[0032] 3. Fetal bovine serum perfused the entire microchannel of the chip, sealed the inlet / outlet of the chip, and put it in a constant temperature incubator at 37°C overnight;

[0033] 4. The mouse embryonic fibroblast (3T3 cell) suspension is poured into the chip pipeline through a micro-injection pump in a sample-pulling manner, and the "dam-like groove" structure 6 can intercept a single or a small number of cells, and the cells are processed. Positioning culture and detection. Microscope to observe the distribution of cells in the chip pipeline. Place the chip in 37°C, 5% CO 2 Cultivated in a constant temperature incubator, photographed and recorded by a mirro...

Embodiment 3

[0036] Fluorescent dyes form a concentration gradient to label cells in different culture channels

[0037] Using the method of realizing the concentration gradient distribution of rhodamine fluorescent dye in the pipeline, a Fluo-4AM dye concentration gradient is formed in the pipeline to mark the PIEC cells cultured in the pipeline. The concentration of Fluo-4AM dye was 10 μM, the injection rate was 1 μl / min, and the fluorescence microscope was observed and recorded, and the emission wavelength was selected as 520 nm.

[0038] Experimental results such as Figure 4 , the fluorescence signal intensities of the cells in the five pipelines showed an obvious trend of change sequentially, indicating that the cells in different pipelines did absorb different concentrations of fluorescent dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com