Silicon carbide water-base casting slurry containing alpha-silicon nitride whisker and preparation method thereof

A technology of silicon nitride water-based and silicon nitride whiskers, which is applied in the field of silicon nitride water-based casting slurry and its preparation, can solve the problems of lack of research materials and data, and achieve simple preparation process and machinability Good, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

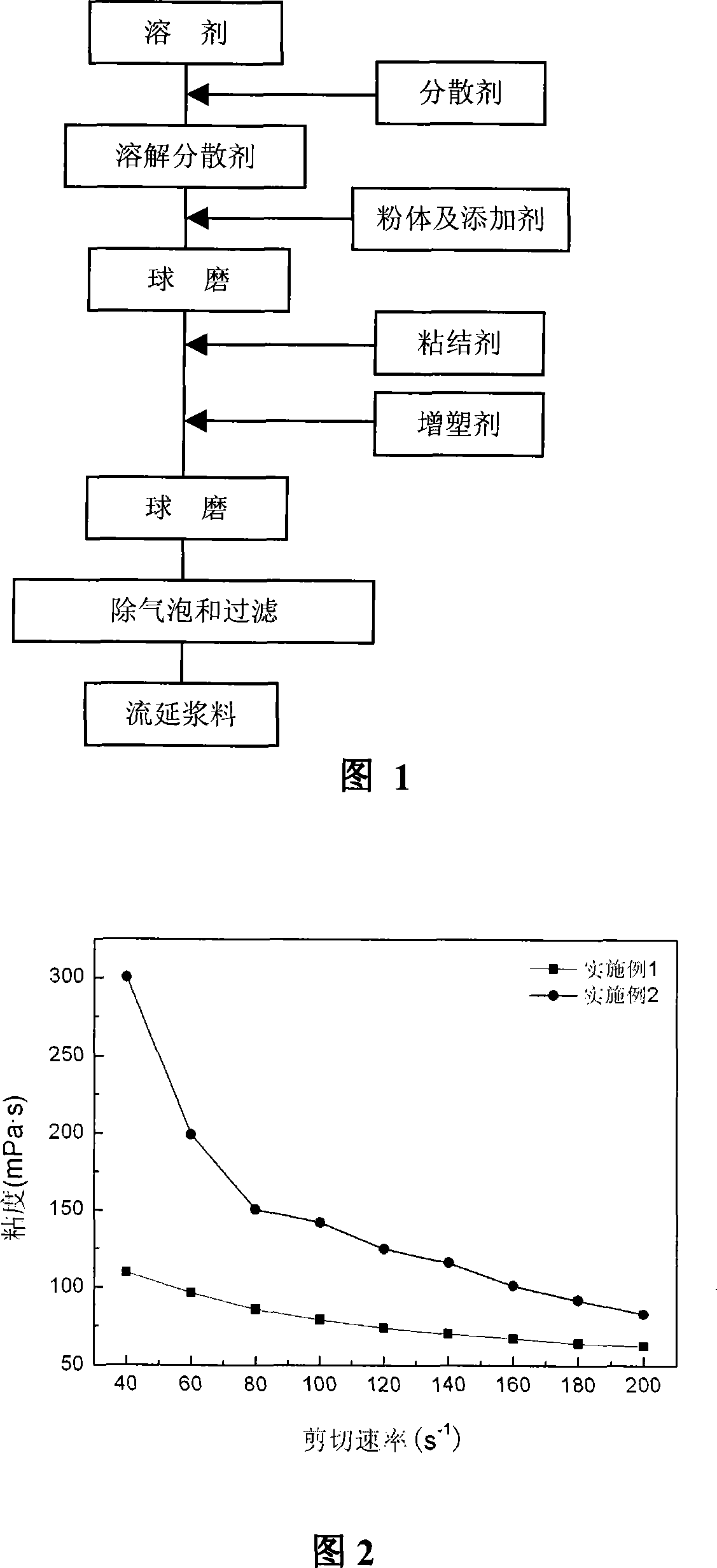

[0020] The preparation process of the slurry of the present invention is shown in Figure 1, including batching, mixing, two ball milling and post-treatment procedures.

[0021] (1) Weigh 1-10% silicon nitride whiskers and 16-25% silicon nitride powder by mass percentage, 1-8% polyethyleneimine as dispersant, and deionized water balance as solvent, Use tetramethylammonium chloride to adjust the pH value of the slurry to 9-11 to ensure that the slurry has a high absolute value of Zeta potential, give full play to the electrostatic repulsion between particles, and obtain Si after ball milling on a ball mill for 6-48 hours 3 N 4 Suspension, balls and tanks used for ball milling are silicon nitride balls and nylon ball milling tanks respectively. The used α-silicon nitride whiskers have an aspect ratio of 10-200 and a diameter of 0.1-0.35 μm; the particle size of the silicon nitride powder is less than 0.5 μm.

[0022] (2) Add 20-35% of polyvinyl alcohol solution as binder and 1-...

Embodiment 1

[0025] Example 1: The solid phase content in the design slurry is 26%, the content of α-silicon nitride whiskers is 3.0%, the content of silicon nitride powder is 25%, and the content of polyethyleneimine is 4%. The content of polyvinyl alcohol is 20%, the content of propylene glycol is 4.1%, adjust pH value with tetramethylammonium chloride to be 9, deionized water surplus, prepare slurry according to the technological process of Fig. 1, rheology as Fig. 2 shown. The micromorphology of the cast film surface obtained after casting is shown in Fig. 5 . The surface of the casting film is smooth, and the powder particles and pores are evenly distributed.

Embodiment 2

[0026] Embodiment 2: The solid content in the design slurry is 26%, the content of α-silicon nitride whiskers is 3.0%, the content of silicon nitride powder is 23%, and the content of polyethyleneimine is 4%. The content of polyvinyl alcohol is 25%, the content of propylene glycol is 3.8%, and the pH value is adjusted to 9 with tetramethylammonium chloride, and the deionized water balance is used to prepare the slurry according to the technological process in Fig. 1, and the rheological properties are as shown in Fig. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com