Method for manufacturing unit doublet carbide codeposition fibre-reinforced composite

A composite material and fiber-reinforced technology, applied in metal material coating process, gaseous chemical plating, coating, etc., to achieve high temperature strength, simple technical process, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

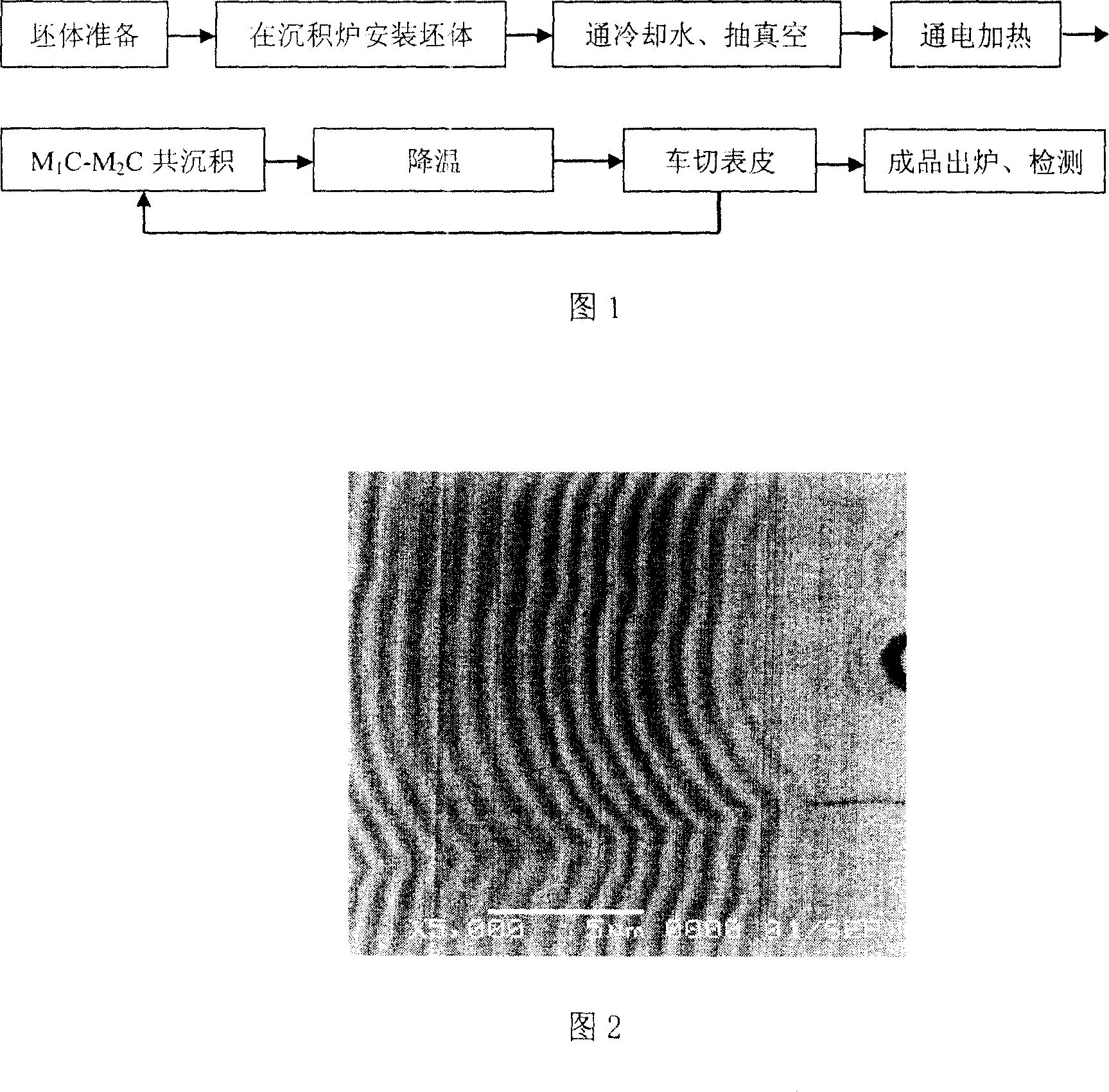

[0015] Embodiment 1: Referring to accompanying drawing 1, Fig. 2, get the C fiber braided body of 3D weaving, cut into the annular sample of Φ (70-100) * 65mm, after weighing, put into chemical vapor deposition furnace; Vacuum to Below 50Pa, heat up to 1100°C, first carry out CVD-C deposition, and pass Ar and C at a ratio of 3:1 3 h 6 Carry out CVD-C deposition, keep the furnace pressure 1000-2000Pa deposition for 20hr; then carry out TaC-SiC co-deposition, use Ar as carrier gas to deposit TaCl 5 introduced into the furnace, while adding C 3 h 6 and reducing gas H 2 , with H 2 CH 3 SiCl 3 (MTS) is brought into the deposition furnace by another pipeline, Ar is used as a dilution gas, and H 2 The ratio with Ar is 1: (1~5), H 2 : MTS ≥ 10, keep the furnace pressure 500 ~ 1000Pa deposition 60hr; stop deposition; continue to pass through Ar for 30min, vacuum cooling; after reaching room temperature, open the furnace to take samples, weigh and test. The carbide crust on the...

Embodiment 2

[0018] Embodiment 2: Referring to accompanying drawing 1, take the SiC fiber braided body of 4D weaving, cut into the annular sample of Φ (70-100) * 65mm, after weighing, put into chemical vapor deposition furnace; Vacuum to below 50Pa, Heating to 1300°C for TaC-HfC co-deposition, using Ar as carrier gas to transfer TaCl 5 Introduced into the furnace while adding CH 4 and reducing gas H 2 , using Ar as the carrier gas to transfer HfCl 4 It is introduced into the deposition furnace through another way, and CH is added at the same time 4 and reducing gas H 2 , Ar as the diluent gas, keep the furnace pressure at 500-1000Pa for deposition for 60 hours; stop the deposition; continue to pass Ar for 30 minutes, vacuumize and cool down; Remove the carbide crust on the inner and outer layers of the diameter by car, ultrasonically clean and dry, put it in a deposition furnace to continue deposition, and repeat TaC-HfC co-deposition several times. A SiC fiber-reinforced TaC-HfC co-d...

Embodiment 3

[0019] Embodiment 3: Referring to accompanying drawing 1, take the boron B fiber (or tungsten W wire) weaving body of 4D weaving, cut into the annular sample of Φ (70-100) * 65mm, after weighing, put into chemical vapor deposition furnace ; Other processes are the same as in Example 2, and the TaC-HfC co-deposition composite material reinforced by dense B fiber (or tungsten W wire) can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com