NiTi shape memory alloy with surface injected with metallic elements and preparation method thereof

A metal element, memory alloy technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as insufficient improvement of corrosion resistance, biocompatibility characterization of NiTi shape memory alloy, etc. To achieve the effect of easy operation, improved wear resistance and biocompatibility, and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a NiTi shape memory alloy whose surface is injected with metal elements comprises the following steps:

[0026] The first step: substrate pretreatment

[0027] Select a NiTi shape memory alloy substrate with nearly equiatomic ratio, after grinding and polishing, ultrasonically clean it with acetone, absolute ethanol and deionized water for 10 min respectively;

[0028] The second step: ion implantation of Hf, Zr or Nb

[0029] (A) Put the pretreated NiTi shape memory alloy substrate into the ion implanter, and set the vacuum pressure of the ion implanter to 1×10 -4 Pa, voltage 5-8KeV, sputtering time 10-30min, carry out argon ion sputtering to remove surface impurities;

[0030] (B) Hf, Zr or Nb implantation in ion implanter:

[0031] Set the vacuum degree of the ion implanter to 1×10 -4 The injection amount of Pa, Hf, Zr or Nb elements is 0.5×10 17 ~2.5×10 17 ions / cm 2 , the voltage is 45KeV, the current is 1-4mA, the ion implantation is c...

Embodiment 1

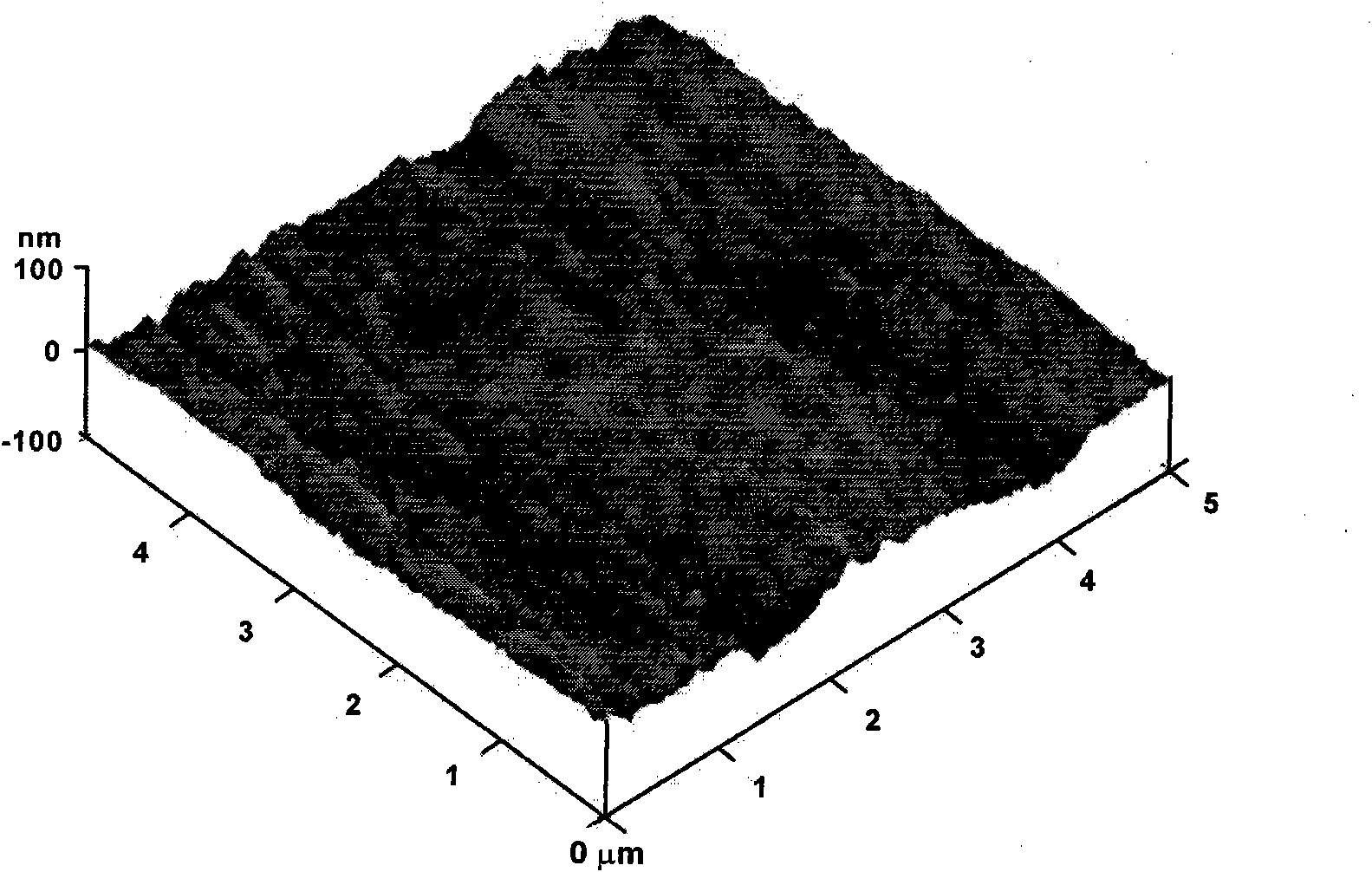

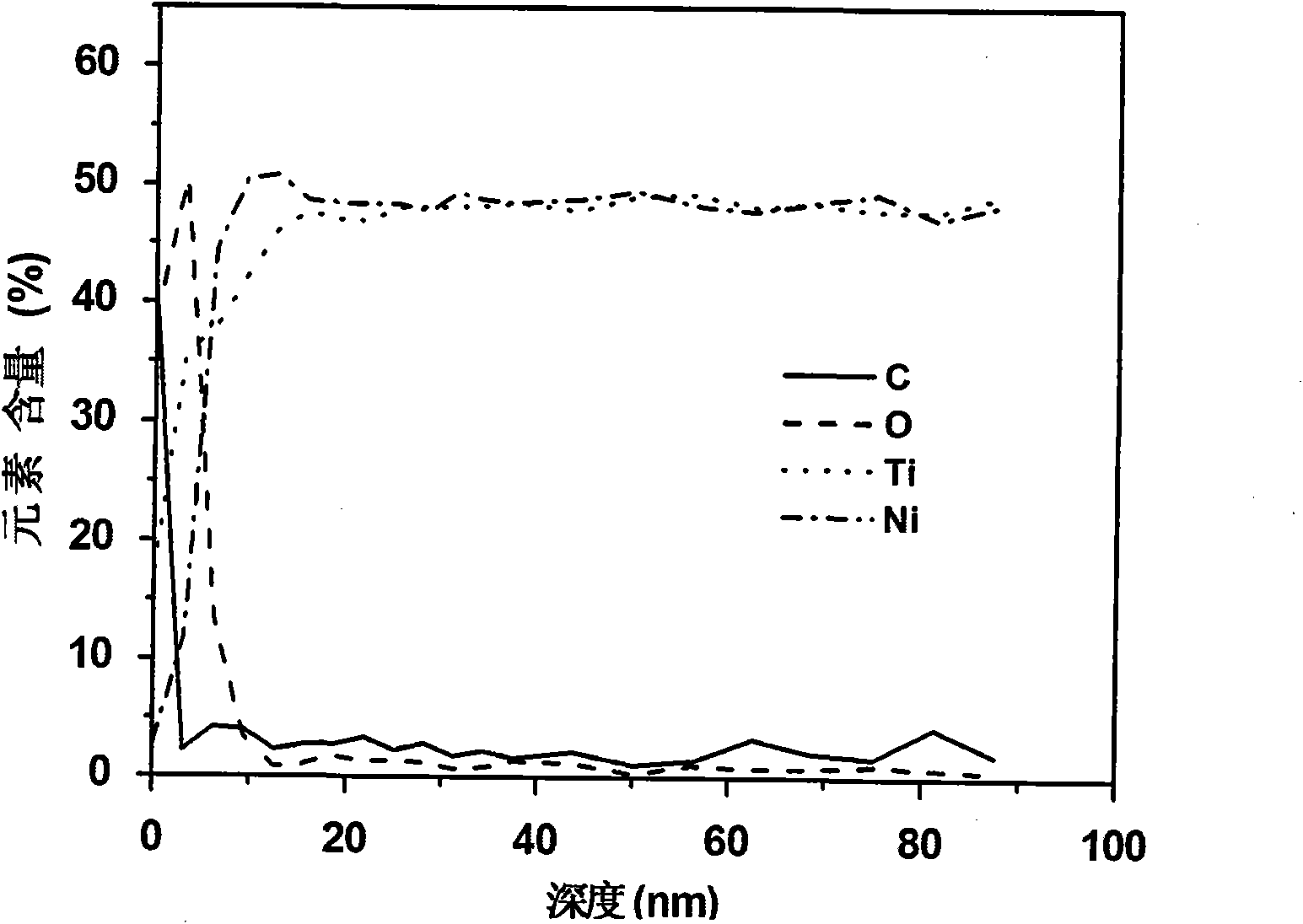

[0034] Example 1: Preparation of NiTi shape memory alloy with Hf implanted on the surface, the Hf element implantation amount is 1.0×10 17 ions / cm 2

[0035] The first step: substrate pretreatment

[0036] Select a NiTi shape memory alloy substrate with nearly equiatomic ratio, after grinding and polishing, ultrasonically clean it with acetone, absolute ethanol and deionized water for 10 min respectively;

[0037] Step 2: Ion implantation into Hf

[0038] (A) Put the pretreated NiTi shape memory alloy substrate into the ion implanter, and set the vacuum degree to 1×10 -4 Pa, voltage 5KeV, sputtering time 20min, carry out argon ion sputtering to remove surface impurities;

[0039] (B) Hf element injection, set the vacuum pressure of the vacuum chamber to 1×10 -4 Pa, Hf element injection amount 1.0×10 17 ions / cm 2 , the voltage is 45KeV, the current is 2mA; the ion implantation is completed 30 minutes after the start of the ion implantation, and the NiTi shape memory allo...

Embodiment 2

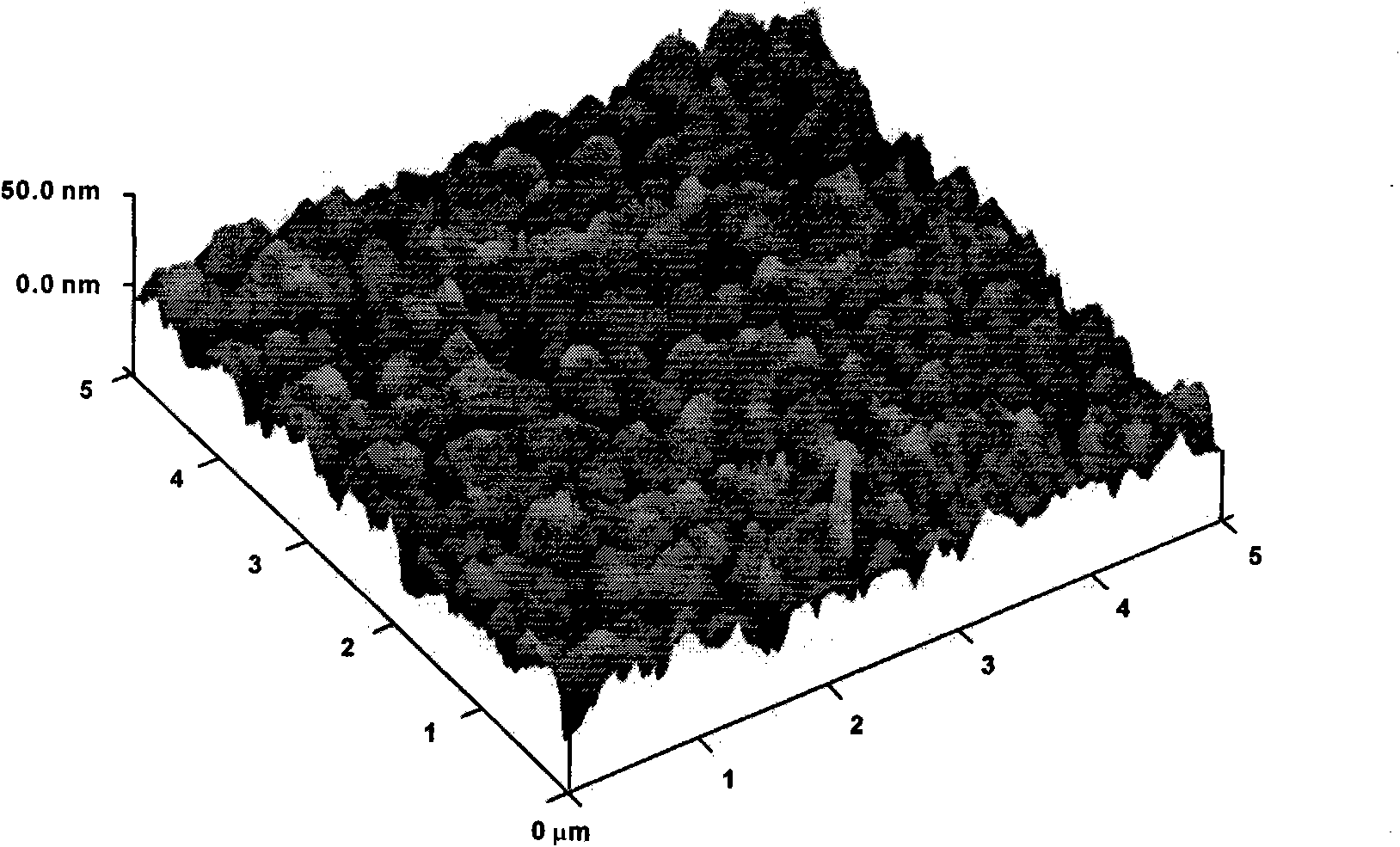

[0056] Example 2: Preparation of NiTi shape memory alloy with Hf implanted on the surface, the Hf element implantation amount is 2.5×10 17 ions / cm 2

[0057] The first step: substrate pretreatment

[0058] Select a NiTi shape memory alloy substrate with nearly equiatomic ratio, after grinding and polishing, ultrasonically clean it with acetone, absolute ethanol and deionized water for 10 min respectively;

[0059] Step 2: Ion implantation into Hf

[0060] (A) Put the pretreated NiTi shape memory alloy substrate into the ion implanter, and set the vacuum degree to 1×10 -4 Pa, voltage 5KeV, sputtering time 20min, carry out argon ion sputtering to remove surface impurities;

[0061] (B) Hf element injection, set vacuum degree 1×10 -4 Pa, Hf element injection amount 2.5×10 17 ions / cm 2 , the voltage was 45KeV, and the current was 2mA; the ion implantation was completed 75 minutes after the start of the ion implantation, and the NiTi shape memory alloy with Hf implanted on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com