Al-W composite material with gradient changing density and its preparation method

A composite material and density gradient technology, used in chemical instruments and methods, heating inorganic powder coating, layered products, etc. Increased density, uniform distribution and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of an Al-W composite material with a density gradient change, comprising the following preparation steps:

[0024] Step 1: Prepare raw materials

[0025] Mix Al powder with a particle size of 10-50 μm and W powder with a particle size of less than 3 μm evenly according to different target components to obtain mixed powders with different W contents; then dry the mixed powders with different W contents in a vacuum oven at 50-85°C for 30- Raw materials with different target components were prepared after 90 minutes;

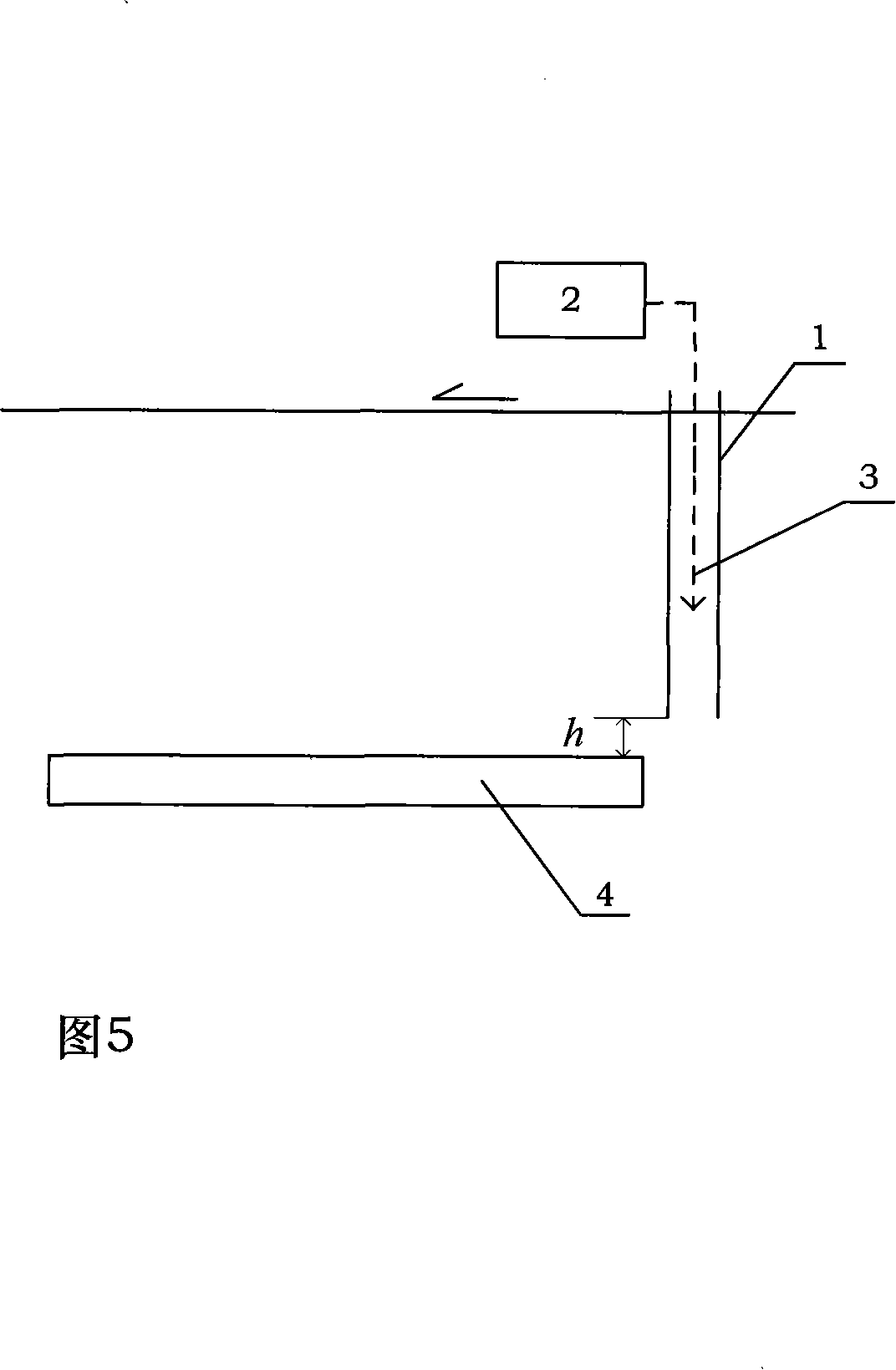

[0026] The second step: Spraying Al-W composite materials with different W content

[0027] Put the raw materials of different target components obtained in the first step into the powder feeder 2 of the spraying equipment, adjust the spraying process parameters, and prepare Al-W composite materials with different densities at room temperature of 18-25°C;

[0028] The process parameters of spraying the first layer are: the working temp...

Embodiment 1

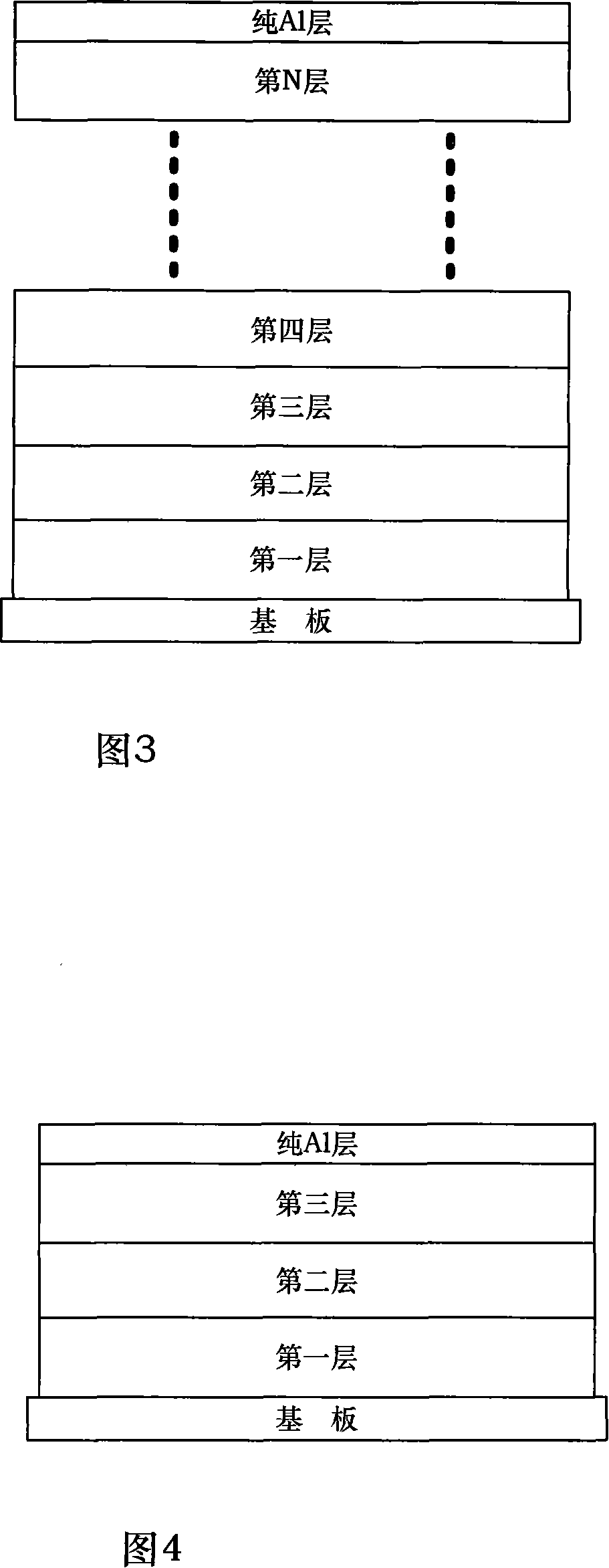

[0044] Example 1: Fabrication of Al-W composites with three-layer structure

[0045] Referring to Fig. 2, the weight percentages of W content in the Al-W composite material with three-layer structure are 94.4%, 63.9%, and 35.5%, respectively. Its preparation process includes the following steps:

[0046] Step 1: Prepare raw materials

[0047] According to the target components with W weight percentage content of 94.4%, 63.9%, and 35.5%, the Al powder with a particle size of 10 μm and the W powder with a particle size of 3 μm are uniformly mixed to obtain a mixed powder with a W content of 94.4%, and a W powder with a W content of 63.9%. Mixed powder, mixed powder with a W content of 35.5%; then (the above mixed powder) mixed powder with a W content of 94.4%, mixed powder with a W content of 63.9%, and mixed powder with a W content of 35.5% are dried in a vacuum oven at 85°C After 30 minutes, raw materials containing 94.4% W, raw materials containing 63.9% W, and raw materia...

Embodiment 2

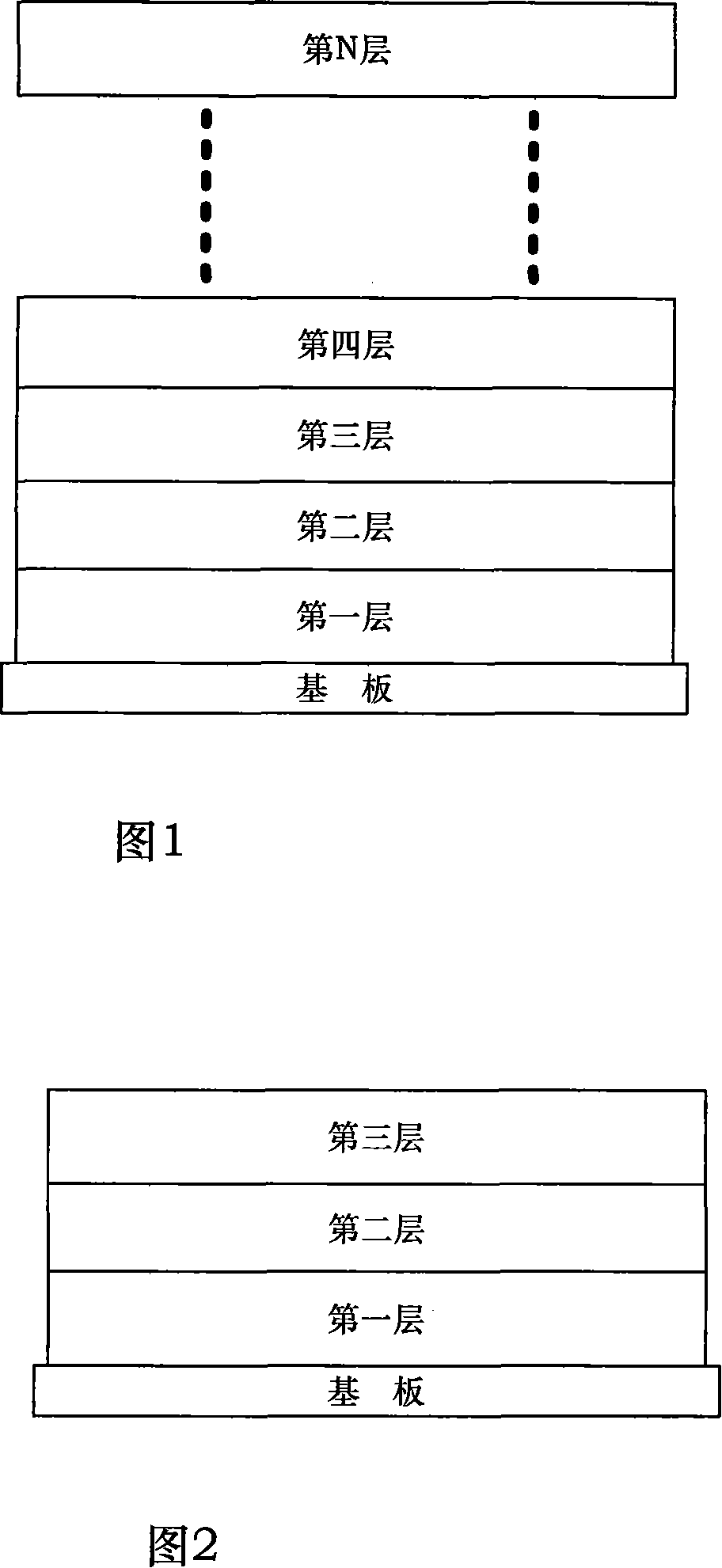

[0059] Example 2: Fabrication of Al-W composites with five-layer structure

[0060] Referring to Fig. 1, the weight percentages of W content in the five-layer Al-W composite material are 92.2%, 87.5%, 79.7%, 70.3%, and 48.8%, respectively. Its preparation process includes the following steps:

[0061] Step 1: Prepare raw materials

[0062] According to the W weight percentage content of 92.2%, 87.5%, 79.7%, 70.3%, 48.8% target components, the Al powder with a particle size of 50 μm and the W powder with a particle size of 1 μm are uniformly mixed to obtain a mixed powder with a W content of 92.2%, W Mixed powder with a content of 87.5%, mixed powder with a W content of 79.7%, mixed powder with a W content of 70.3%, and mixed powder with a W content of 48.8%; Mixed powder, mixed powder with W content of 79.7%, mixed powder with W content of 70.3%, and mixed powder with W content of 48.8% were dried in a vacuum oven at 50°C for 90 minutes to obtain a raw material with a W co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com