Method for preparing onion-shaped internal coating metal nickel carbon particle with deoiling asphalt

A technology of deoiling asphalt and metal nickel, which is applied in the direction of coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

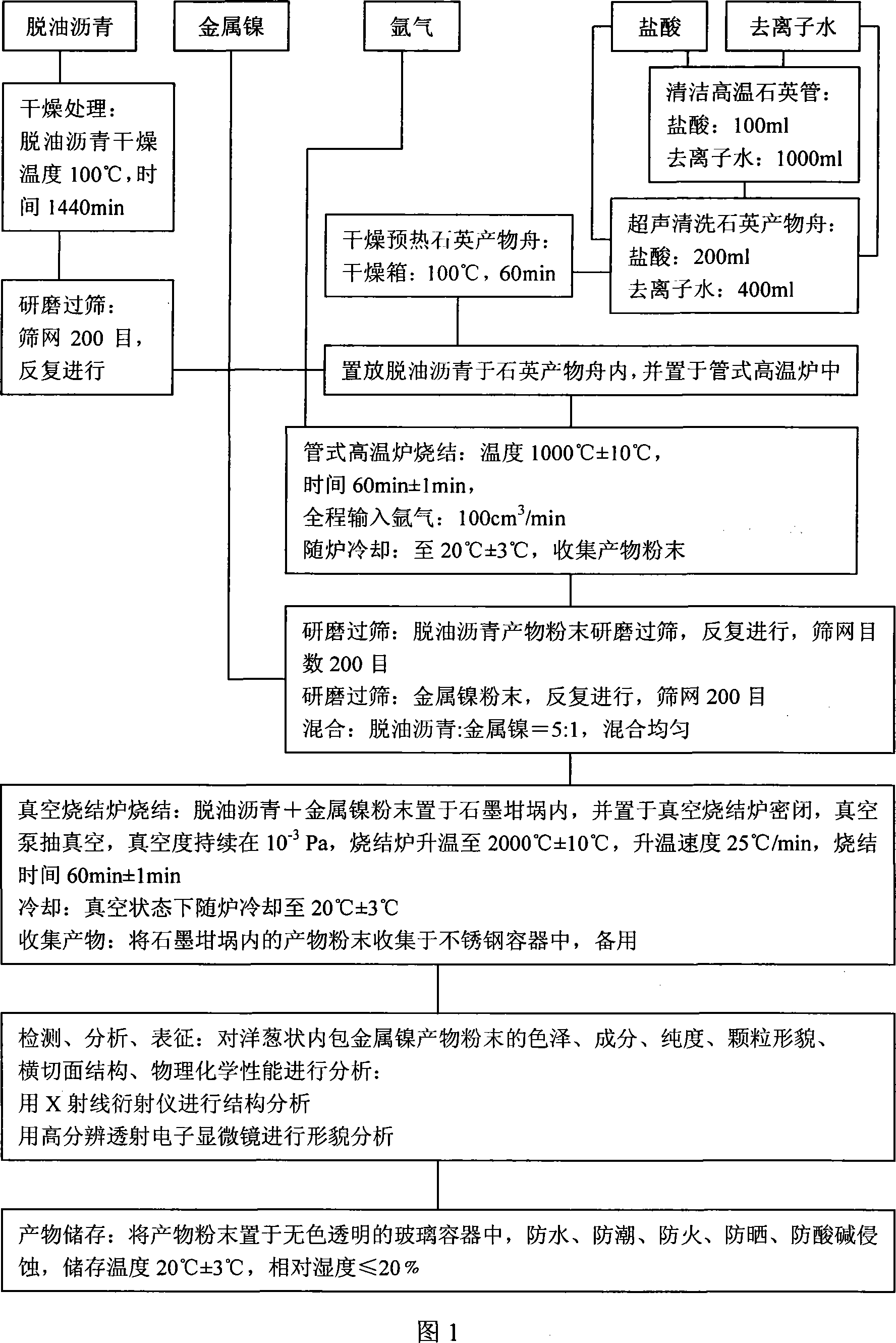

[0102] The present invention will be further described below in conjunction with accompanying drawing:

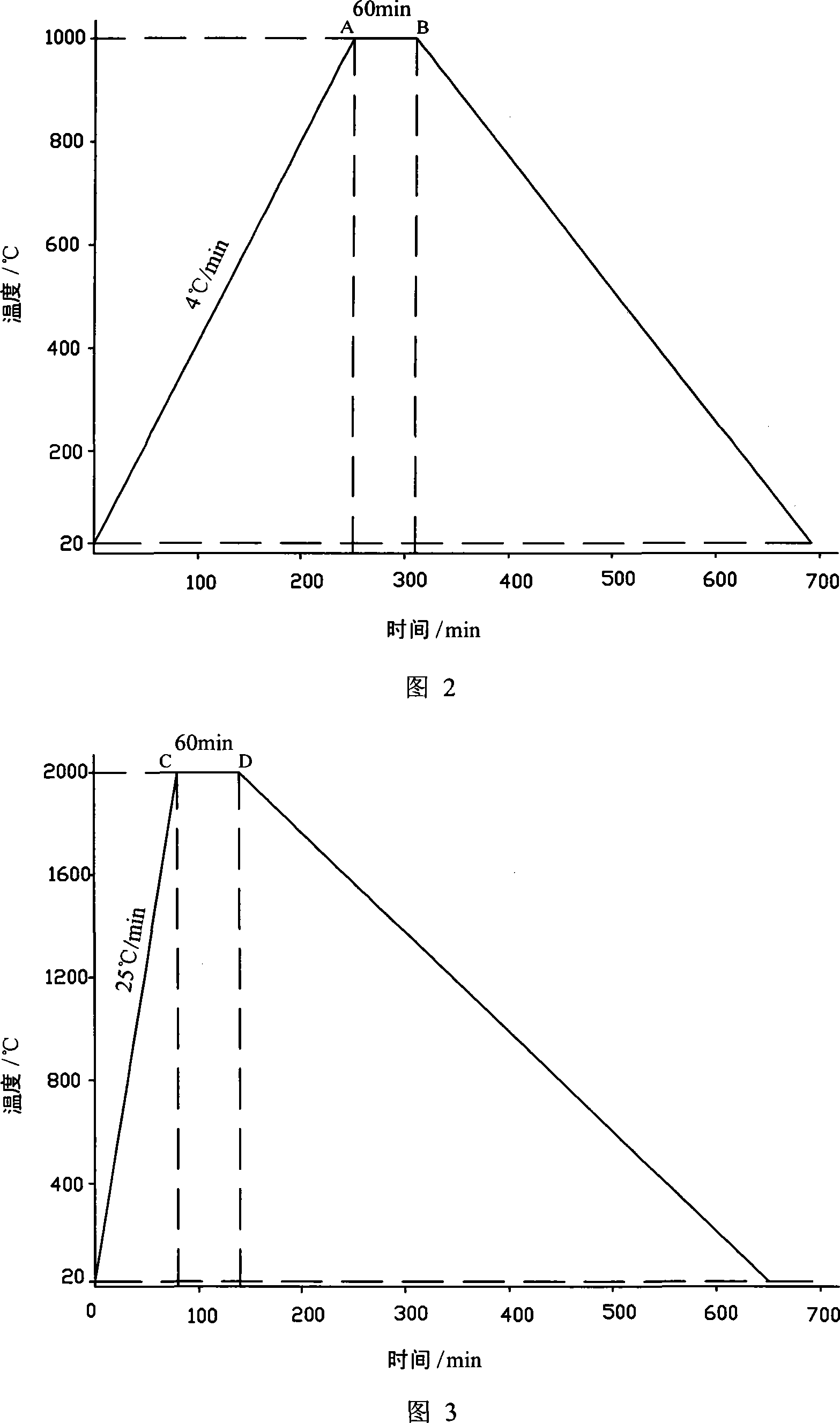

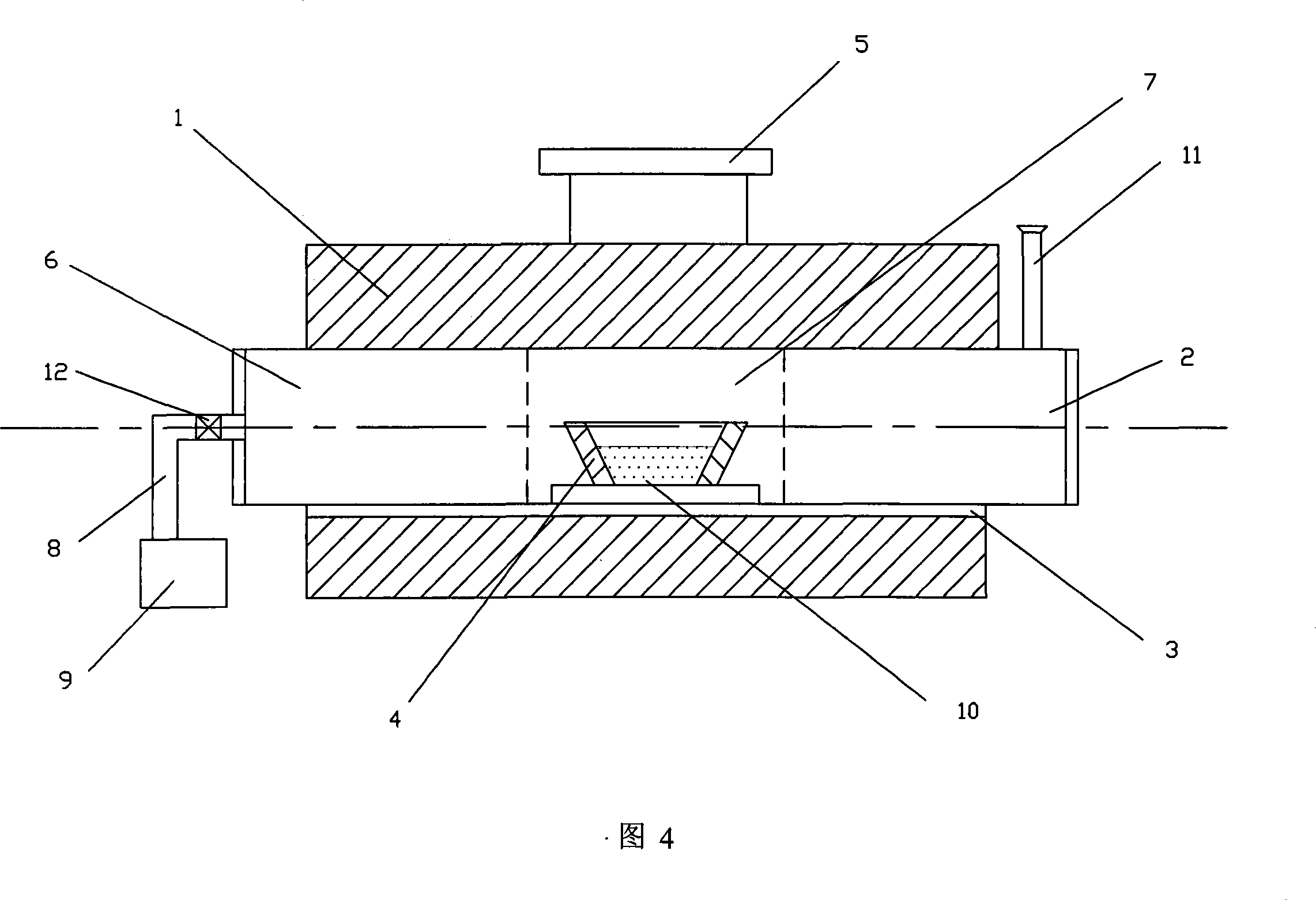

[0103] As shown in Fig. 1, it is a preparation process flow chart, and each preparation parameter should be strictly controlled, and its combination ratio value is preset in the test, with grams, milliliters, and centimeters as the unit of measurement. Kilograms, liters, and meters are units of measurement.

[0104] The chemical raw materials required for preparation: deoiled asphalt, metal nickel, hydrochloric acid, deionized water, and argon gas must be strictly selected, and the purity and fineness should be controlled, and no impurities should be involved to prevent by-products from being generated.

[0105] The chemical substances required for preparation must be strictly weighed, and the ratio of deoiled asphalt powder + metal nickel powder must be configured strictly according to the amount of 5:1, and the ratio must not exceed the range.

[0106] The inert protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com