High-ammonia nitrogen low C/N ratio waste water treatment process and use thereof

A wastewater treatment, high ammonia nitrogen technology, applied in biological water/sewage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Clear, difficult to maintain biological concentration, slow proliferation of nitrifying bacteria, etc., to achieve the effect of less sludge output, small footprint, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

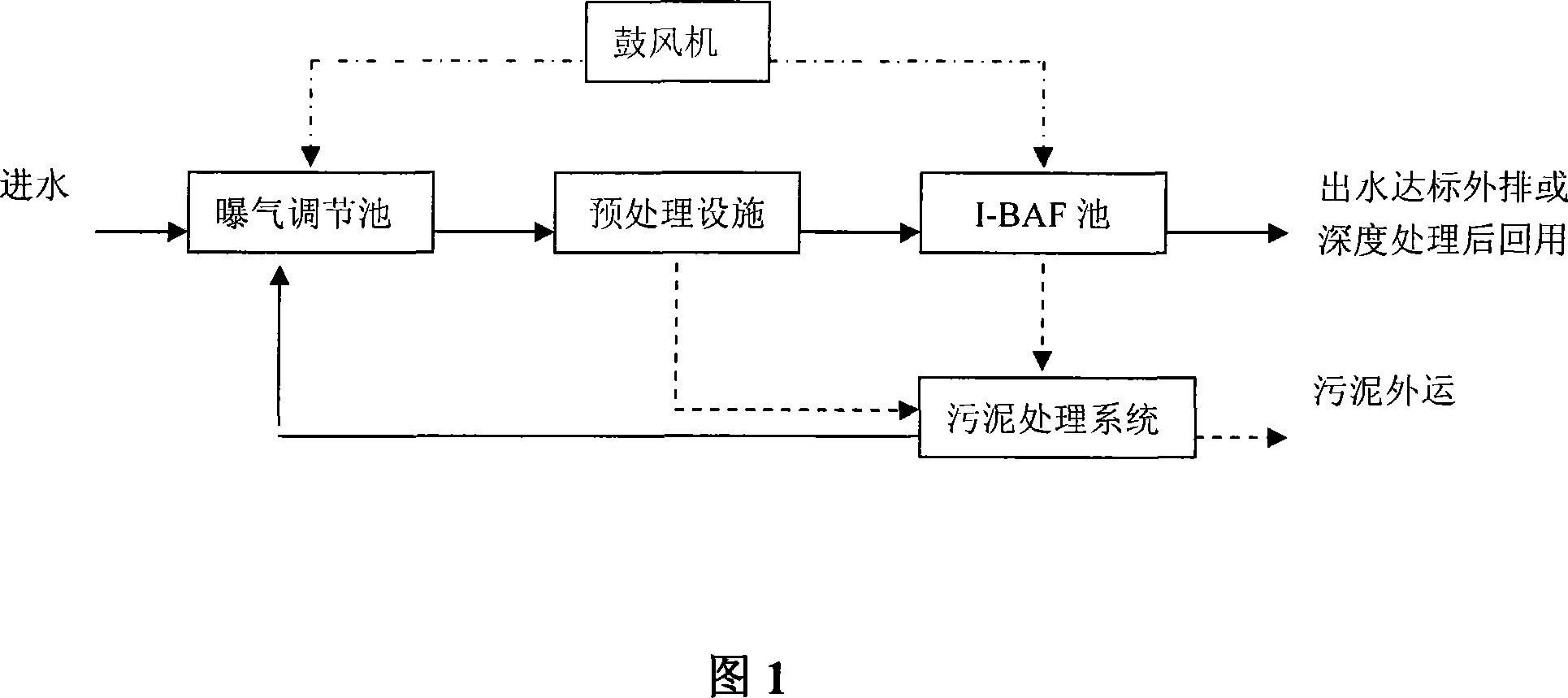

Method used

Image

Examples

Embodiment 1

[0032] A starch factory uses corn as raw material to produce high-quality starch, and the daily sewage discharge volume is 1300m 3 / d, the existing sewage treatment process is "UASB (anaerobic) + SBR (aerobic) + biological contact oxidation". The UASB process runs stably and the treatment effect is good. When the influent COD is 8000-12000mg / L, the effluent COD is generally about 800mg / L, and the effluent COD of SBR is 300-400mg / L, but the operation effect of the contact oxidation process is poor, and the effluent COD≥180mg / L, NH 3 -N exceeds the standard seriously, and cannot meet the relevant effluent discharge standards. Using S-IBAF as the main process to carry out small test experiments on site, the experimental water flow rate is 4L / h, the effective volume of the IBAF reaction tank is 80L, the hydraulic retention time is 20h, and the carrier loading is 60% (high-efficiency carrier accumulation volume 48L), the inoculated microorganisms are engineering bacteria. The in...

Embodiment 2

[0034] A monosodium glutamate factory uses corn starch as raw material to produce monosodium glutamate, and the daily sewage discharge volume is 8000m 3 / d, the existing sewage treatment process is "UASB (anaerobic) + SBR (aerobic)". SBR effluent COD is 100-200mg / L, NH 3 -N exceeds the standard seriously, and cannot meet the relevant effluent discharge standards. Using S-IBAF as the main process to carry out small test experiments on site, the experimental water flow rate is 4L / h, the effective volume of the IBAF reaction tank is 60L, the hydraulic retention time is 15h, and the carrier loading is 60% (high-efficiency carrier accumulation volume 36L), the inoculated microorganisms are engineering bacteria, and the influent of the experiment is the effluent of the sewage treatment plant. Water NH 3 -N concentration ranges from 154.3mg / L to 361.6mg / L, effluent NH 3 -N concentration is between 0.01mg / L and 0.21mg / L.

Embodiment 3

[0036] A chemical company is the largest small-scale nitrogen fertilizer enterprise in Hebei Province. Its main product production capacity is 135,000 tons of synthetic ammonia, 200,000 tons of urea, and 30,000 tons of methanol. 3 . S-IBAF combined process is used for terminal wastewater treatment, the pretreatment process is radial flow sedimentation tank, and the effective volume of IBAF is 2250m 3 , the hydraulic retention time is 27h, and the loading capacity of the carrier is 53% (the accumulation volume of the high-efficiency carrier is 1200m 3 ), the inoculated microorganisms are engineering bacteria. As of the beginning of August 2007, it has been in continuous and stable operation for 3 months, and the influent CODcr is 500-800mg / L, BOD 5 300-500mg / L, SS 300-1000mg / L, NH 3 - When N is 500-700mg / L, CODcr in effluent water quality is 81-108mg / L, BOD 5 8-15mg / L, SS 40-70mg / L, NH 3 -N is 4.8-12mg / L, which can continuously and stably reach the first-level discharge st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com