High-speed air-blowing static spinning composite preparation method and device for ultra-fine polymer fibre

An electrospinning and ultrafine fiber technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc. The effect of uniform diameter and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

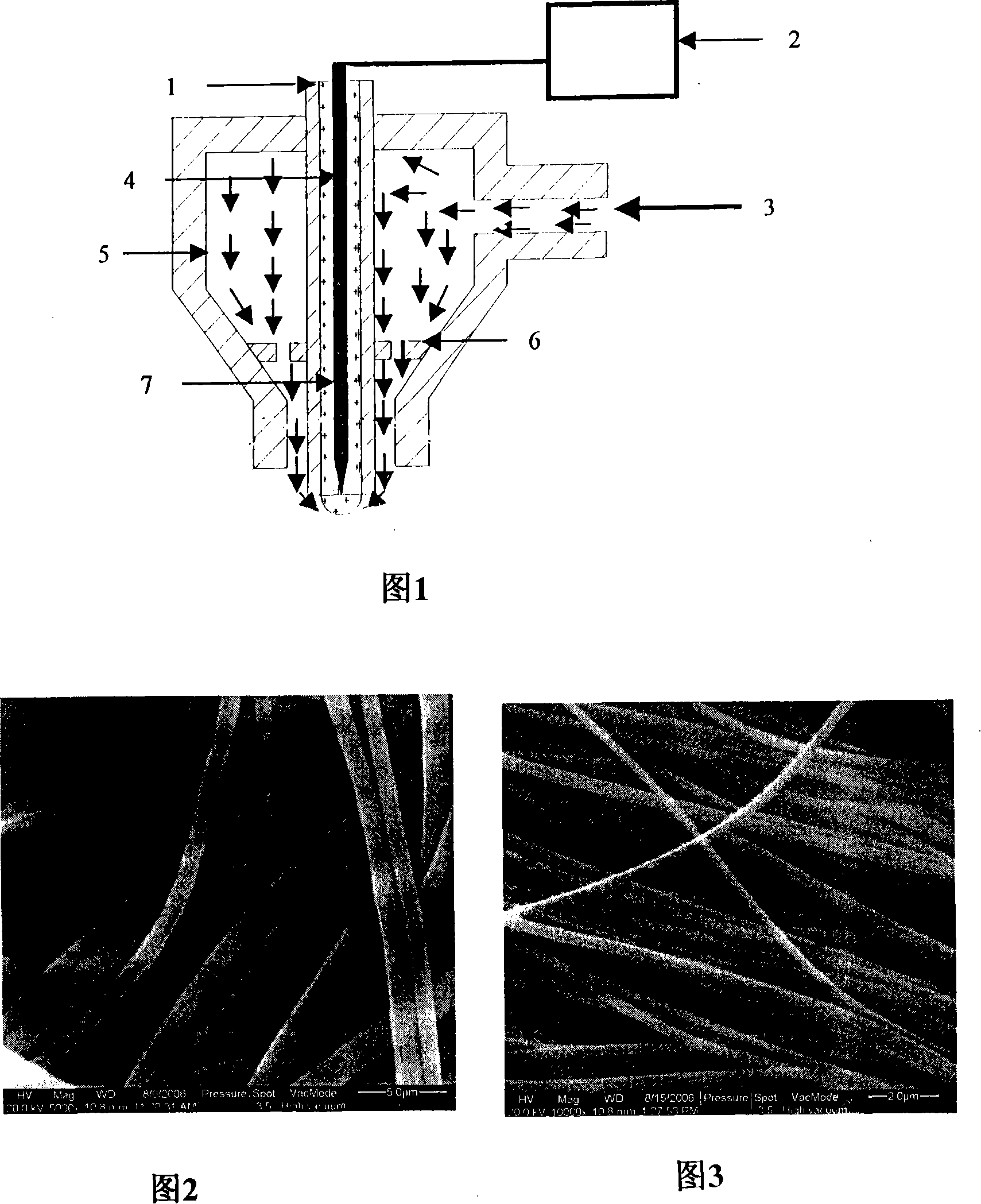

[0017] Example 1: A device for composite preparation of ultrafine polymer fibers by high-speed air-blowing electrospinning includes: nozzles, high-voltage power supplies, metal needles, and nozzle jackets are tapered tubes, and the middle part of the nozzles is provided with polymer solution nozzles 4, There is a metal needle 7 in the center of the nozzle 4, and the tail of the metal needle 7 is connected to the high-voltage power supply 2. There is an air uniform valve 6 between the nozzle 4 and the nozzle casing. The side wall of the nozzle casing is provided with a high-pressure air outlet 3 and a high-pressure air outlet 3 It is connected with the uniform gas valve and nozzle 4. The pipe wall between the jackets of the device prepared by high-speed air-blowing electrospinning of ultrafine polymer fibers separates the air flow and the polymer solution. A constant pressure is applied to the polymer solution, and the polymer solution flows out from the nozzle inner tube polym...

example 2

[0018] The preparation method of example 2 polyacrylonitrile (PAN) spinning solution

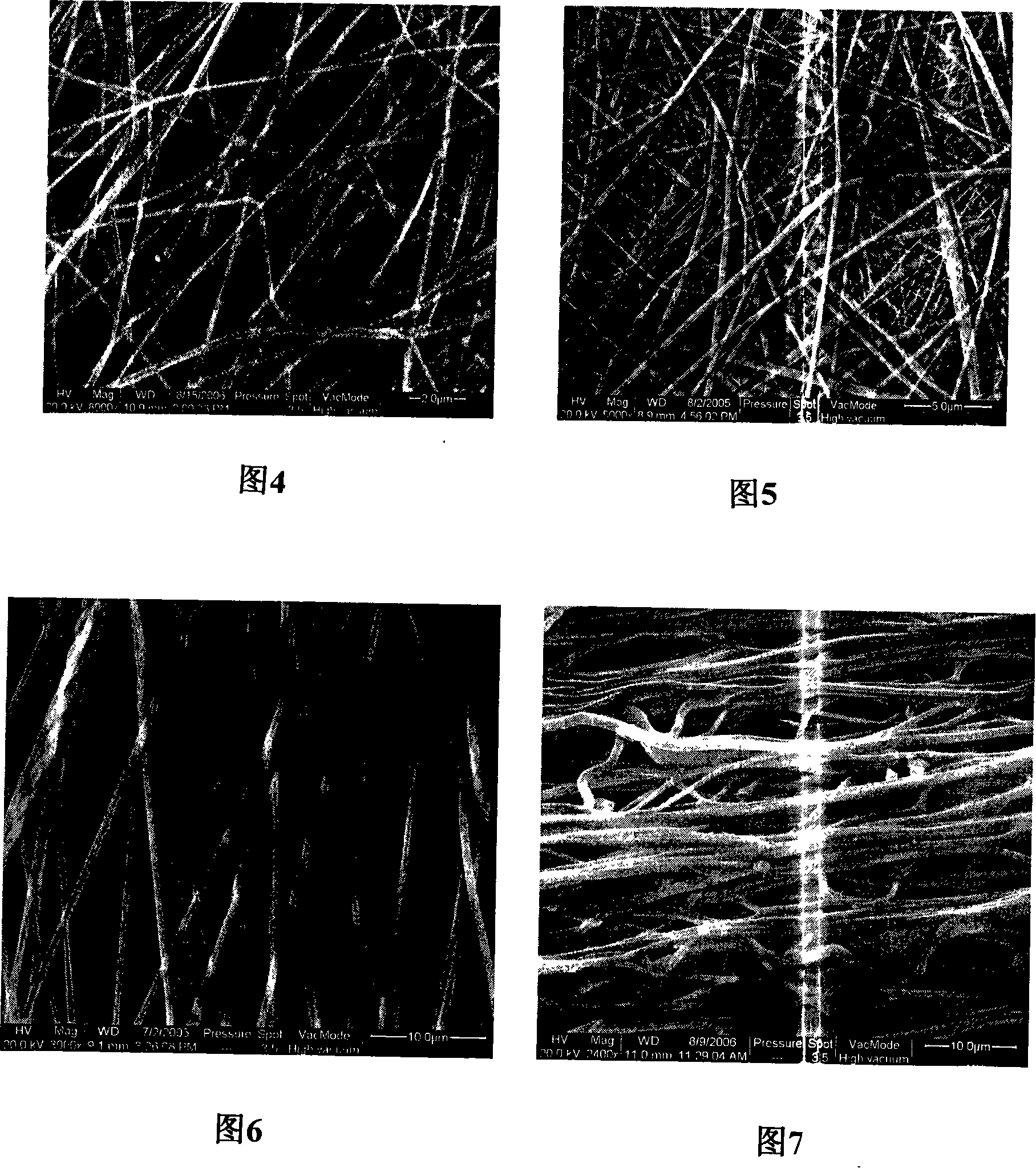

[0019] Weigh 10g of PAN with an intrinsic viscosity of 2.3dl / g, add 90g N'N-dimethylacetamide (DMAc), control the solution mass concentration to be about 10%, add about 0.2% cetyltrimethyl Ammonium bromide (DEMAB) was used to increase the conductivity of the solution, and stirred at 100°C for 2 hours to form a uniform and transparent solution. The electric field strength of spinning is 50kV / m, the gas flow rate is 10L / min, the gas flow rate of the spinneret is 204m / s, the solution consumption (single nozzle) is 0.3ml / min, and the diameter of the nanofiber is 800-1500nm. The SEM photo of PAN nanofibers is shown in Figure 2.

example 3

[0020] The preparation method of example 3 polyamic acid (PAA) spinning solution

[0021] Take 50 g of the original PAA / DMAc solution with a synthetic concentration of about 15% and an intrinsic viscosity of 2.02dl / g, add 5 g of tetrahydrofuran (THF) to dilute to a total mass concentration of the solution of about 12%, and add about 0.2% of organic salt DEMAB was stirred at 0°C for 2 hours to form a uniform and transparent solution. The electric field strength of spinning is 60KV / m, the gas flow rate is 20L / min, the gas flow rate of the spinneret is 408m / s, the solution consumption (of a single nozzle) is 0.25ml / min, and the diameter of the nanofiber is 390-700nm. The SEM photo of PAA nanofibers is shown in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com