Sub-wavelength continuous surface micro-structure preparation method based on negative refractive rate lens

A negative refractive index and sub-wavelength technology, which is applied in the field of sub-wavelength continuous surface microstructure preparation, can solve the problem that the processing range is difficult to expand to the sub-wavelength scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

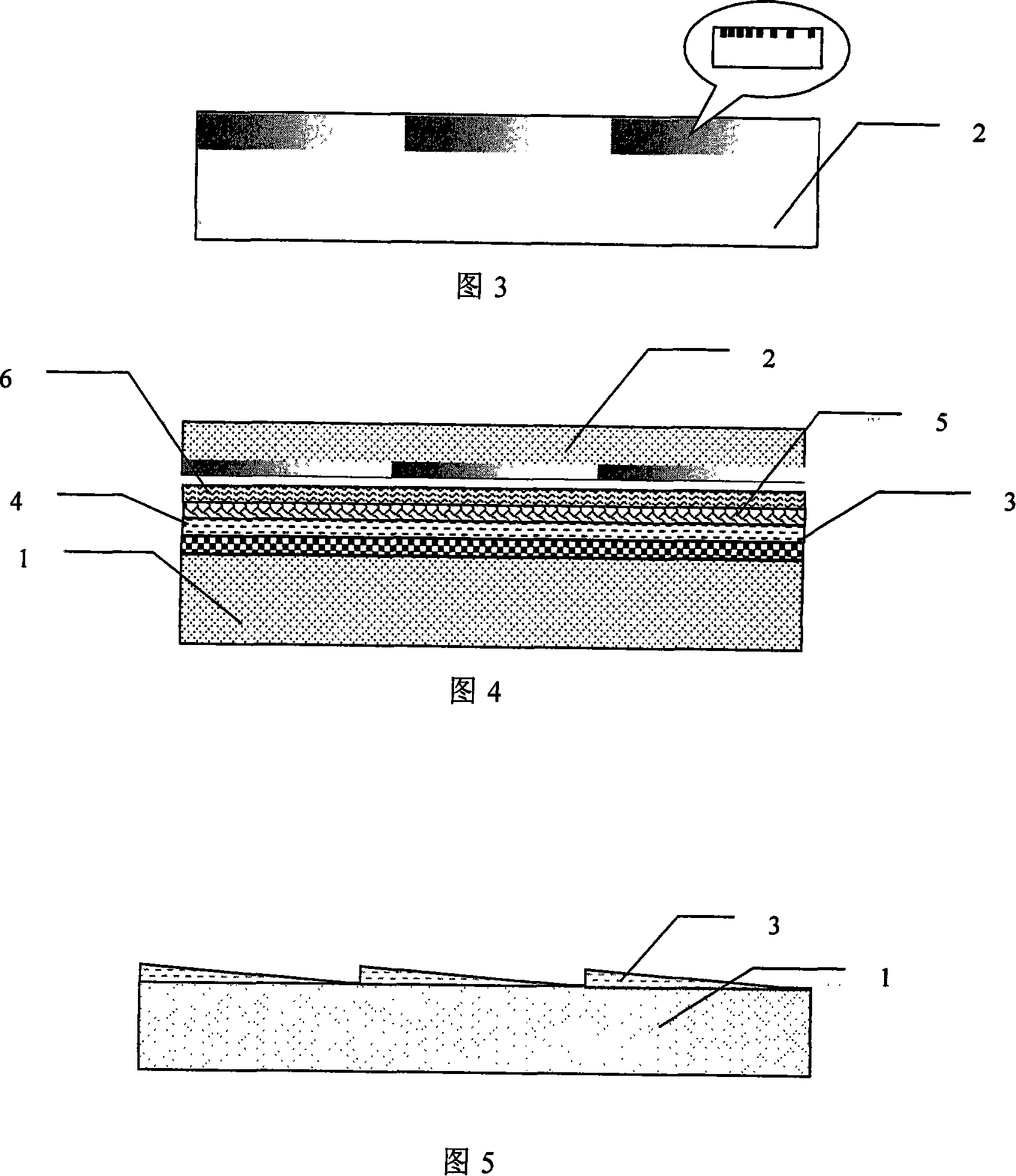

[0027] The present invention will be described in detail below in conjunction with specific embodiments, but the scope of protection of the present invention is not limited to the following examples, and should include all content in the claims.

[0028] In the specific embodiment of the present invention, only the metal silver layer is taken as an example. The main similarities between the metal gold layer and the metal silver layer are both used as negative refractive index lenses. identical. In addition, the various materials used as the spacer layer and gap layer, whether they are organic materials or inorganic materials, have exactly the same functions, and the process operation steps are also exactly the same. Therefore, the present invention only provides an embodiment, and other implementation modes are completely the same as the embodiment.

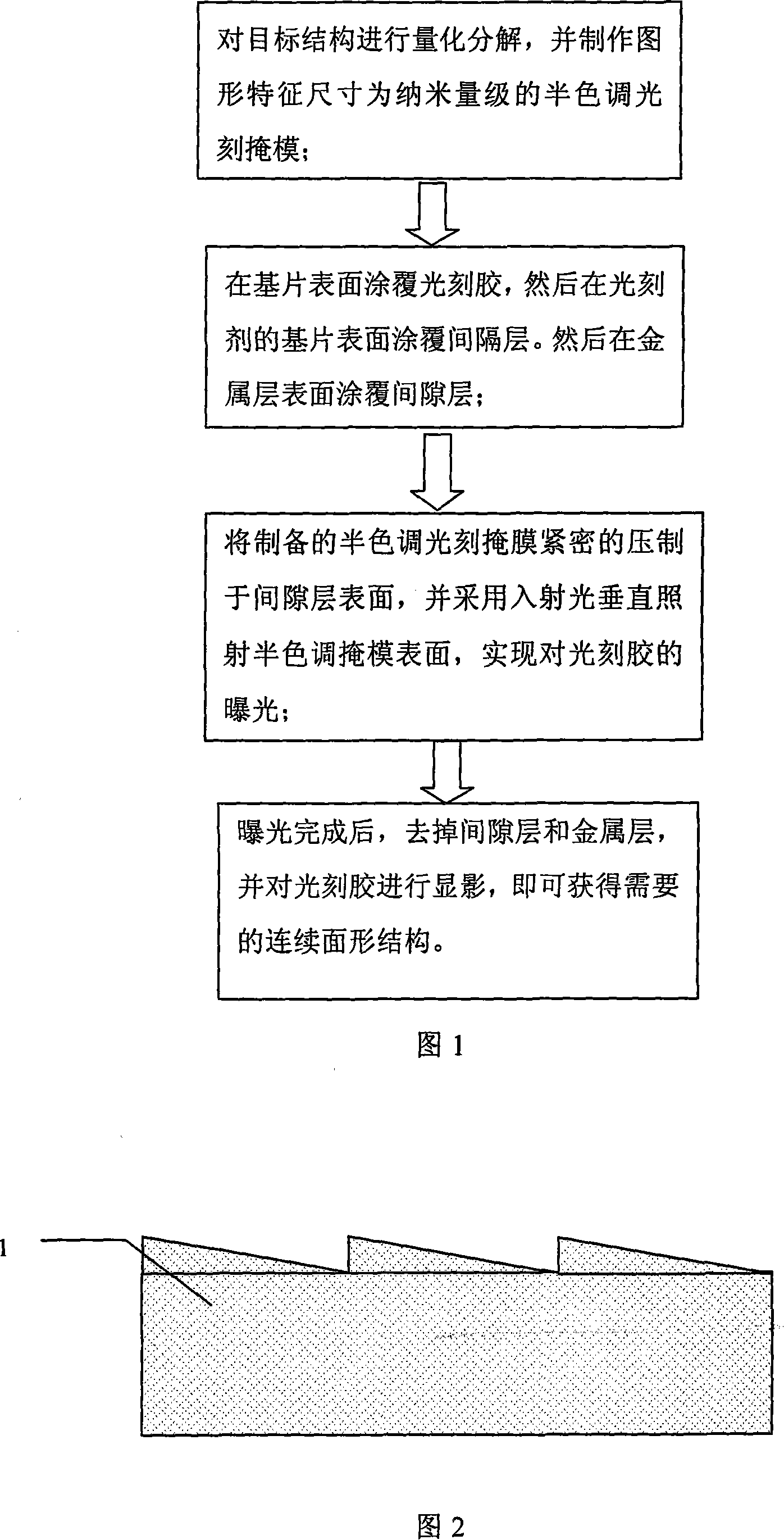

[0029] The specific implementation steps of the present invention are as follows:

[0030] (1) For the target structure of qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com