Carbon-free casting powder for casting steel making die

A mold slag and die casting technology, applied in the field of auxiliary materials for steel-making ingots, can solve the problems of poor spreadability and thermal insulation properties of mold slag, poor thermal insulation and spreading properties, low melting point viscosity, etc. Good thermal insulation performance and good melting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

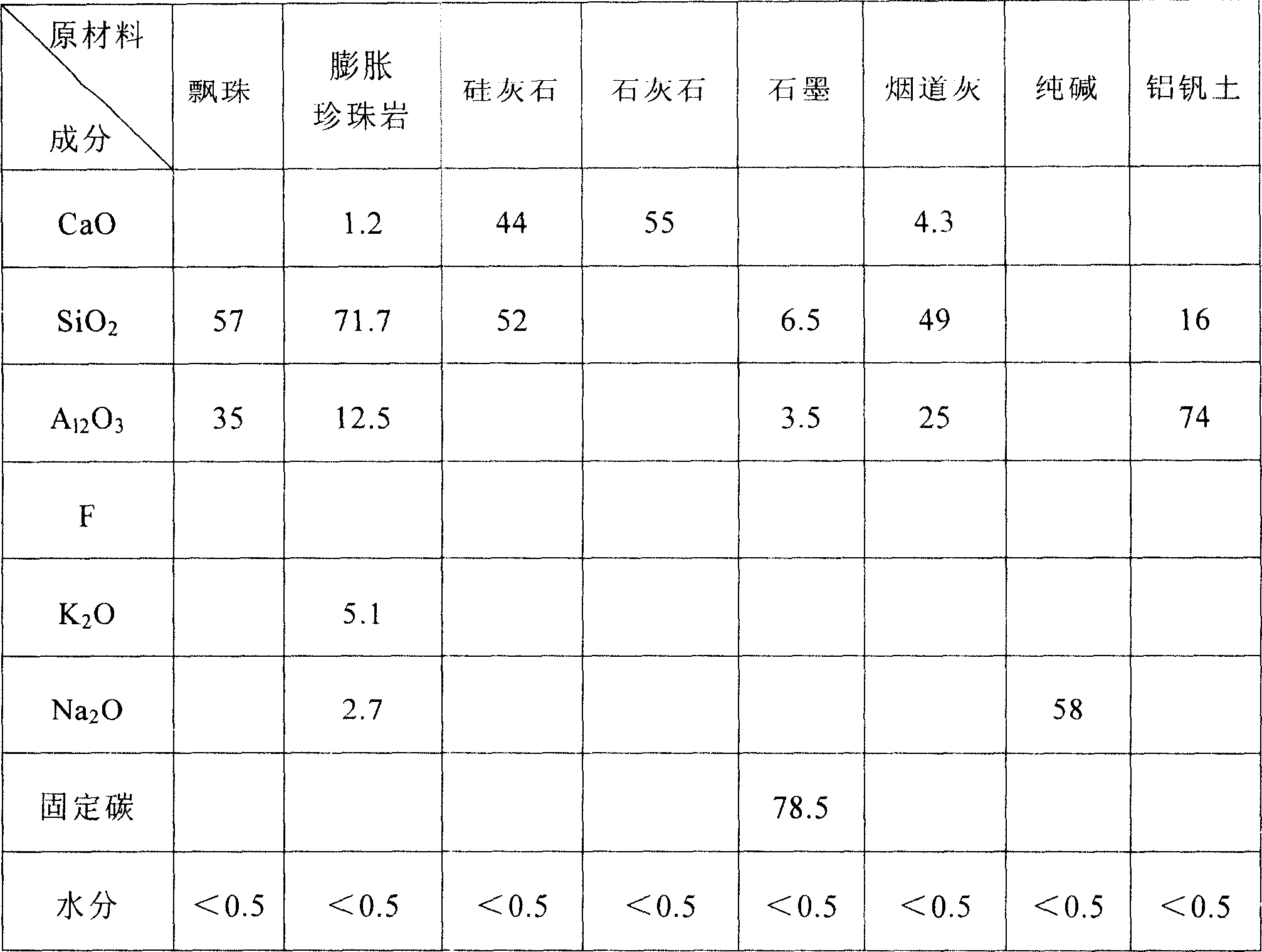

[0035] The formula of carbon-free mold flux for steelmaking mold casting is: containing CaO, SiO 2 and a small amount of Al 2 o 3 The wollastonite is the basic slag material, and the addition amount is 57wt%; it contains SiO 2 、Al2 o 3 The floating beads, the addition amount is 20wt%; contains SiO 2 、Al 2 o 3 The expanded perlite, the addition amount is 15wt%; Industrial soda ash, the addition amount is 8wt%.

[0036] The particle size control of the above-mentioned wollastonite, expanded perlite and industrial soda ash is: greater than 0.25 mm and less than 0.9%, less than 0.044 mm and not less than 57%; the particle size of floating beads is 100% less than 0.36 mm.

[0037] In this example, the physical properties of mold flux are: melting temperature is 1312°C; viscosity (1400°C Pa.s) is 1.7; bulk density is 0.39g / cm 3 .

[0038] The effect of using mold flux is: good melting performance, no carburization, and excellent surface quality of billets.

Embodiment 2

[0040] The formula of carbon-free mold flux for steelmaking mold casting is: containing CaO, SiO 2 and a small amount of Al 2 o 3 The wollastonite is the basic slag material, the addition amount is 50wt%; it contains SiO 2 、Al 2 o 3 The floating beads, the addition amount is 15wt%; contains SiO 2 、Al 2 o 3 The added amount of expanded perlite is 25wt%; industrial soda ash is added in an amount of 10wt%.

[0041] The particle size control of the above-mentioned wollastonite, expanded perlite and industrial soda ash is: greater than 0.25 mm and less than 0.8%, less than 0.044 mm and not less than 56%; the particle size of floating beads is 100% less than 0.35 mm.

[0042] In this example, the physical properties of mold flux are: melting temperature is 1310°C; viscosity (1400°CPa.s) is 1.6; bulk density is 0.31g / cm 3 .

[0043] The effect of using mold flux is: good melting performance, no carburization, and excellent surface quality of billets.

Embodiment 3

[0045] The formula of carbon-free mold flux for steelmaking mold casting is: containing CaO, SiO 2 and a small amount of Al 2 o 3 The wollastonite is the basic slag material, the addition amount is 68wt%; it contains SiO 2 、Al 2 o 3 The floating beads, the addition amount is 9wt%; contains SiO 2 、Al 2 o 3 The added amount of expanded perlite is 18wt%; industrial soda ash is added in an amount of 5wt%.

[0046] The particle size control of the above-mentioned wollastonite, expanded perlite and industrial soda ash is: greater than 0.25 mm and less than 0.85%, less than 0.044 mm and not less than 62%; the particle size of floating beads is 100% less than 0.34 mm.

[0047] In this example, the physical properties of mold flux are: melting temperature is 1340°C; viscosity (1400°C Pa.s) is 1.3; bulk density is 0.37g / cm 3 .

[0048] The effect of using mold flux is: good melting performance, no carburization, and excellent surface quality of billets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com