Bacillus licheniformis fibrinolytic enzyme and production method thereof

A Bacillus licheniformis and production method technology, applied in the field of bioengineering, can solve the problems of low enzyme production level, high price, and defects in enzymatic properties, and achieve the effects of short process flow, high production efficiency, and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Medium and culture method:

[0047] The strains were stored on a slant in LB medium. Firstly, the strains were cultured at 37°C for 24 hours, and then inoculated into the liquid fermentation medium.

[0048] The liquid fermentation medium contains 2% glucose, 2% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, and extract the juice), KH 2 PO 4 1%, K 2 HPO 4 0.5%, MgSO 4 0.45%, pH natural.

[0049] The inoculum size is 1%, the fermentation temperature is 37°C, the shaker speed is 140r / min, and the maximum enzyme activity obtained is 320IU / ml after culturing for 38 hours.

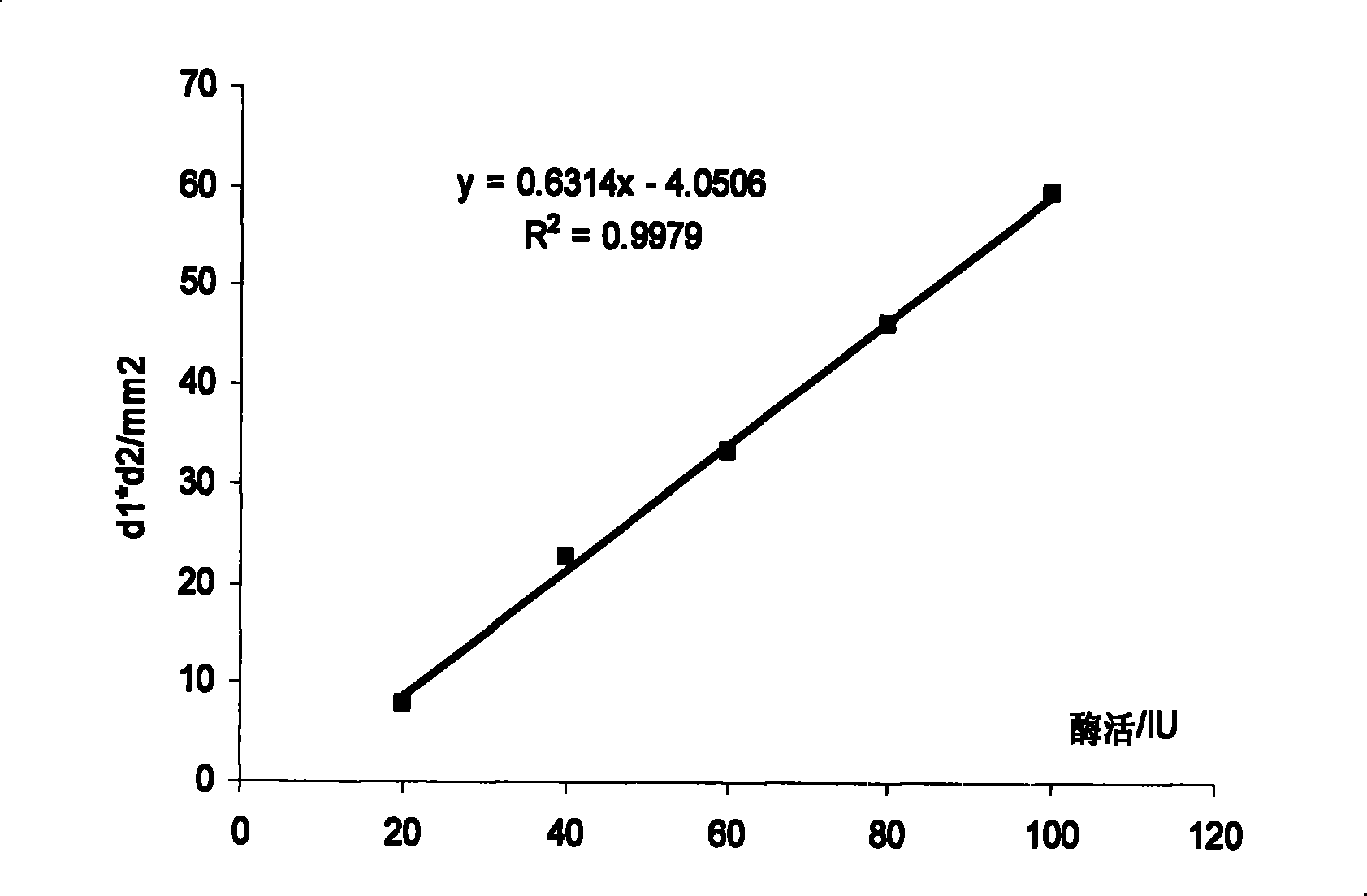

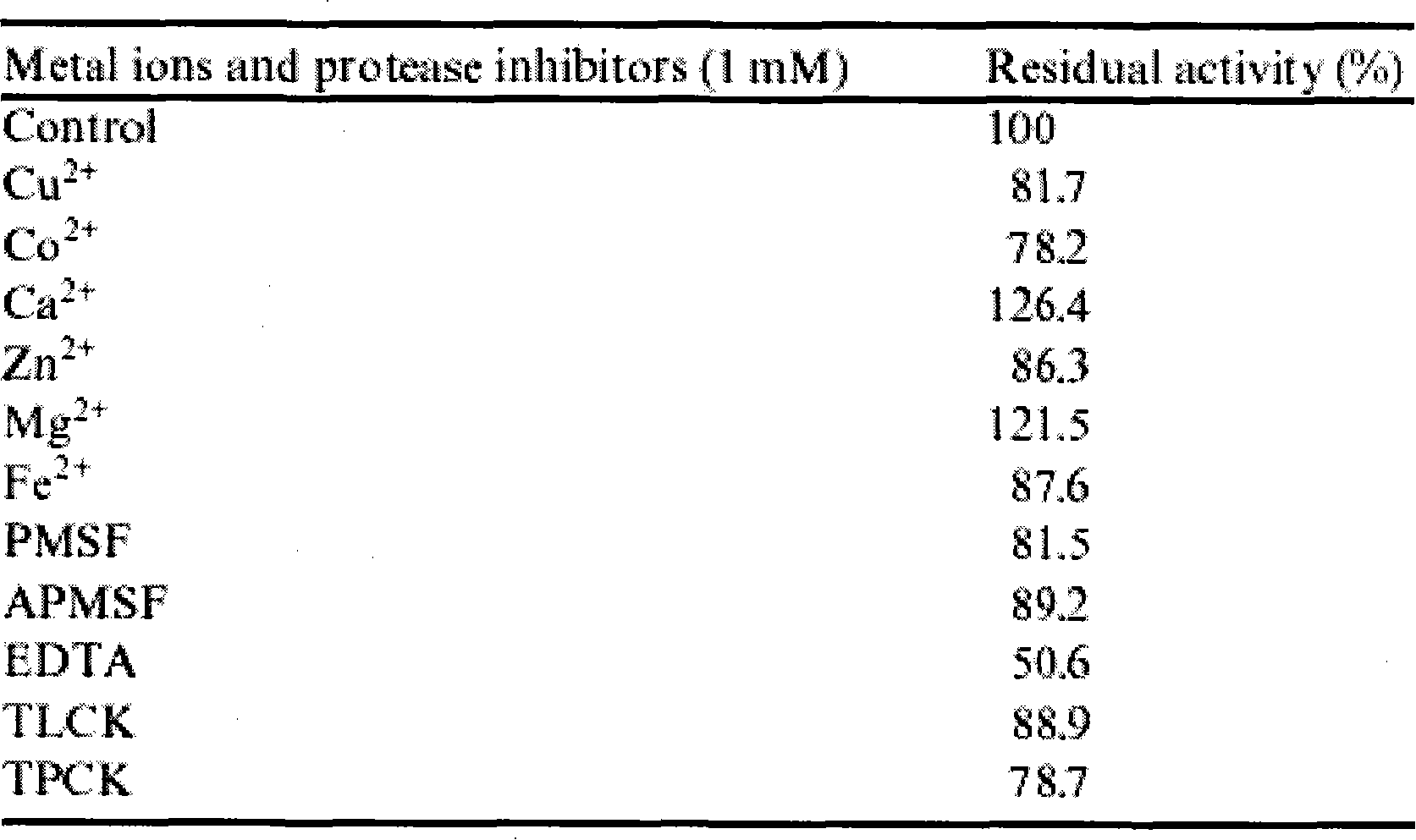

[0050] Rough purification of enzymes: The fermentation broth was subjected to high-speed refrigerated centrifugation at a speed of 12,000r / min and a temperature of 4°C to remove the bacteria to obtain a supernatant, which was decolorized by a gel column Sephadex G-50 and then used in mass percent concentration Carry out segmental salti...

Embodiment 2

[0054] The strains were stored on a slant in LB medium. Firstly, the strains were cultured at 37°C for 24 hours, and then inoculated into the liquid fermentation medium.

[0055] The liquid fermentation medium contains 2% bran, 2% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, filter to obtain juice), KH 2 PO 4 1%, K 2 HPO 4 0.5%, MgSO 4 0.45%, pH natural. The inoculation amount is 1%, the fermentation temperature is 37° C., the shaking table rotation speed is 120 r / min, and the maximum enzyme activity obtained is 510 IU / ml after culturing for 72 hours.

[0056] According to the rough purification of enzyme in embodiment 1 and the fine purification method of enzyme, obtain the higher bacillus licheniformis plasmin of enzymatic activity, through SDS-PAGE analysis, its molecular size is 30KD; The specific activity of this enzyme is 52000IU / mg protein.

Embodiment 3

[0058] The strains were stored on a slant in LB medium. Firstly, the strains were cultured at 37°C for 24 hours, and then inoculated into the liquid fermentation medium.

[0059] The liquid fermentation medium contains 4% bran, 2% yeast extract, 10% soybean juice (preparation method: soak 10% soybeans for 24 hours, simmer for 30 minutes, filter to obtain juice), CaCl 2 0.1%, KH 2 PO 4 1%, K 2 HPO 4 0.5%, MgSO 4 0.45%, pH natural. The inoculum size is 1%, the fermentation temperature is 37°C, the shaking table rotation speed is 140r / min, and the maximum enzyme activity obtained is 590IU / ml after culturing for 72 hours.

[0060] According to the rough purification of the enzyme in Example 1 and the refined purification method of the enzyme, the higher Bacillus licheniformis plasmin of enzyme activity is obtained, and through SDS-PAGE analysis, its molecular size is 30KD; Finally freeze-drying obtains the higher enzyme activity eluent samples. The specific activity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com