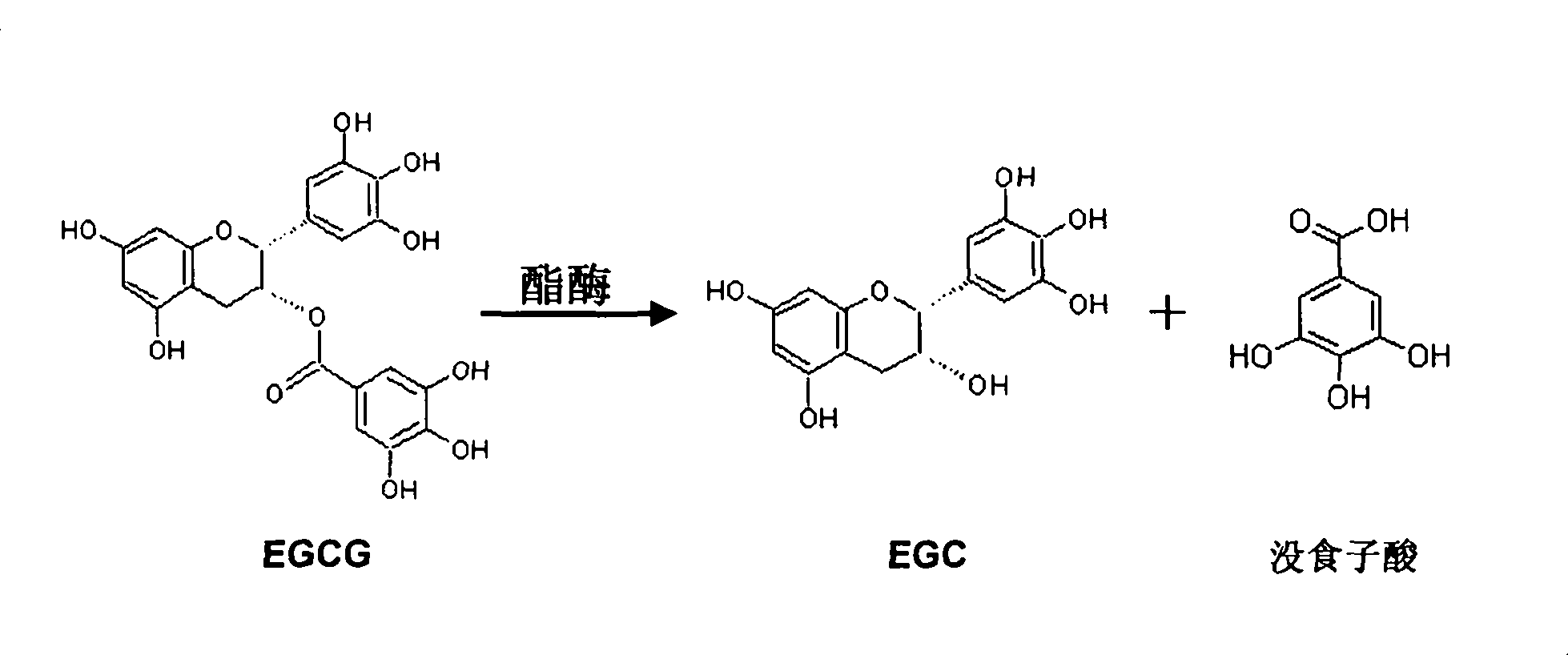

Induction preparation of EGCG esterase and method for producing EGC and gallic acid by using the enzyme

A technology of gallic acid and esterase, which is applied in the field of preparation and catalytic conversion of enzymes, can solve the problems of low hydrolysis rate, low enzyme output, easy oxidation, etc., and achieve high conversion rate, simple operation and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Seed culture of Aspergillus niger ATCC 46890

[0033] Aspergillus niger seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N; use Aspergillus niger ATCC 46890 as the production strain, at pH 5.0, 30°C, 200r / Min conditions for 36 hours.

[0034] 2. Fermentation of Aspergillus niger to produce enzymes

[0035] Aspergillus niger enzyme production medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, add EGCG to a final concentration of 2.5g / L, pH5.0; at 4% inoculum size , at 30°C and 160r / min for 72h to induce enzyme production. The fermented supernatant liquid collected by filtration or centrifugation is the EGCG hydrolase liquid. In the experiment, the fermentation culture without adding EGCG was used as the control.

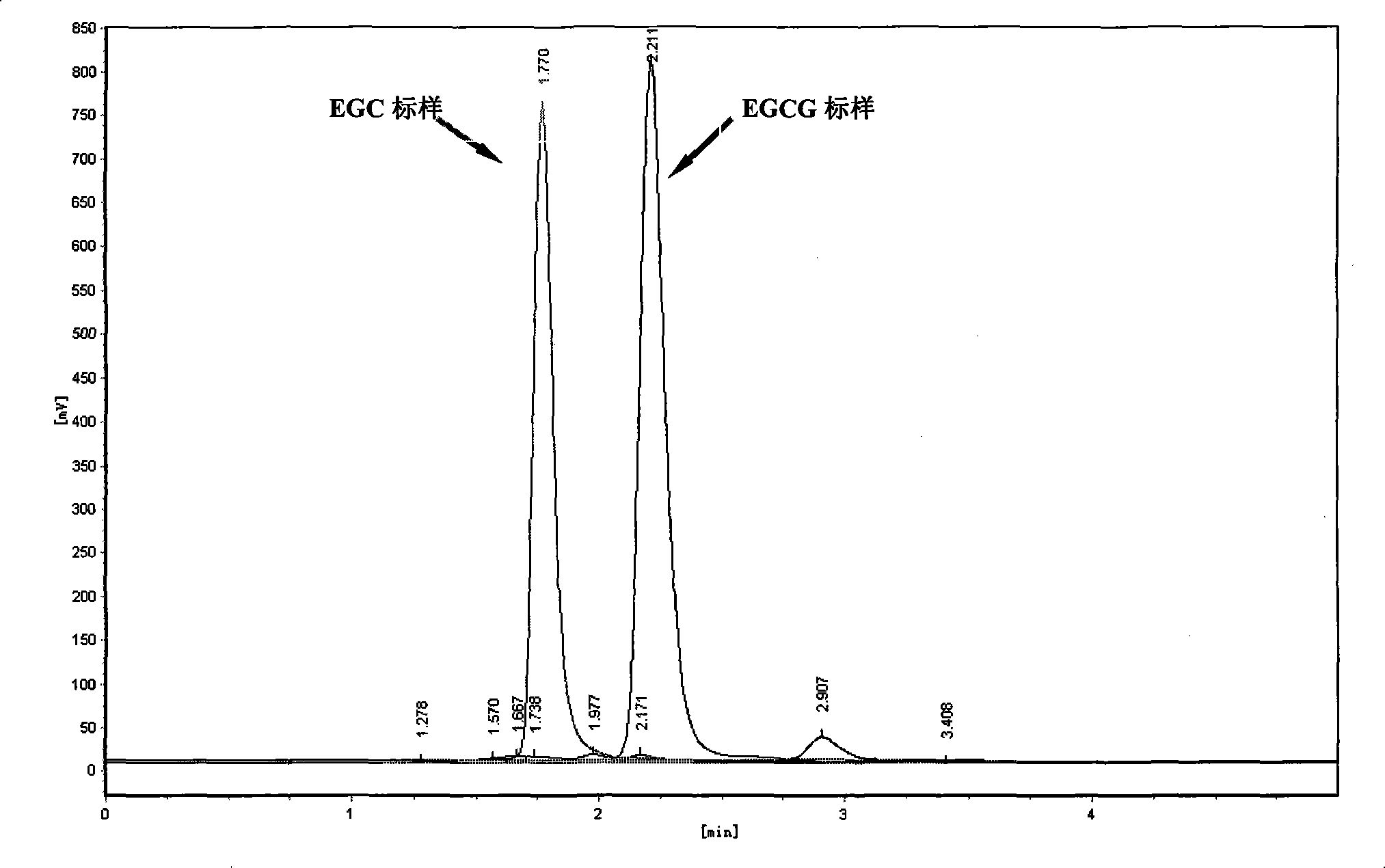

[0036] 3. Enzymatic hydrolysis of EGCG

[0037] Reaction system: 10g / L EGCG substrate 2mL, EGCG hydrolase solution 2mL, pH5.2 acetate buffer 2mL; EGCG hydrolase solutio...

Embodiment 2

[0042] 1. Seed culture of Aspergillus niger MC 57

[0043] Aspergillus niger seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N; Aspergillus niger MC 57 was used as the production strain, pH 5.0, 30°C, 200rpm culture 36 hours.

[0044] 2. Fermentation of Aspergillus niger to produce enzymes

[0045] Aspergillus niger enzyme production medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, add EGCG to a final concentration of 5.0g / L, pH5.0; at 8% inoculum size , at 30°C and 160r / min for 72h to induce enzyme production. The fermented supernatant liquid collected by filtration or centrifugation is the EGCG hydrolase liquid. In the experiment, the fermentation culture without adding EGCG was used as the control.

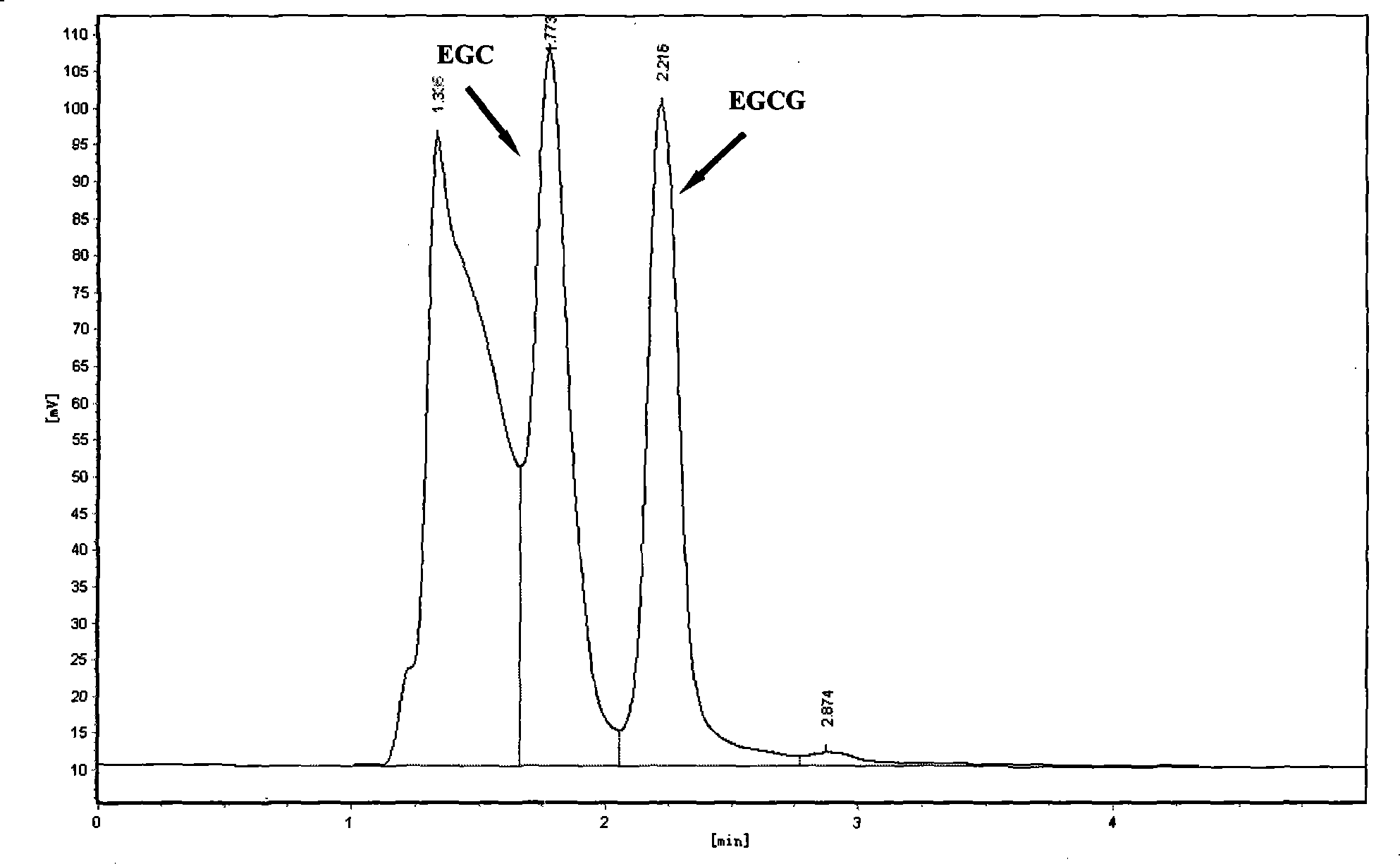

[0046] 3. Enzymatic hydrolysis of EGCG

[0047] Reaction system: 15g / L EGCG substrate 2mL, EGCG hydrolase solution 2mL, pH5.2 acetate buffer 2mL; EGCG hydrolase solution blank system: pH5....

Embodiment 3

[0050] 1. Seed culture of Aspergillus niger ATCC 46890

[0051] Aspergillus niger seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N; use Aspergillus nigerATCC 46890 as the production strain, at pH 5.0, 30°C, 200r / min for 36 hours.

[0052] 2. Fermentation of Aspergillus niger to produce enzymes

[0053] Aspergillus niger enzyme production medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, add EGCG to a final concentration of 10.0g / L, pH5.0; at 8% inoculum size , at 30°C and 130r / min for 72h to induce enzyme production. The fermented supernatant liquid collected by filtration or centrifugation is the EGCG hydrolase liquid. In the experiment, the fermentation culture without adding EGCG was used as the control.

[0054] 3. Enzymatic hydrolysis of EGCG

[0055] Reaction system: 30g / L EGCG substrate 2mL, EGCG hydrolase solution 2mL, pH5.2 acetate buffer 2mL; EGCG hydrolase solution blank sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com