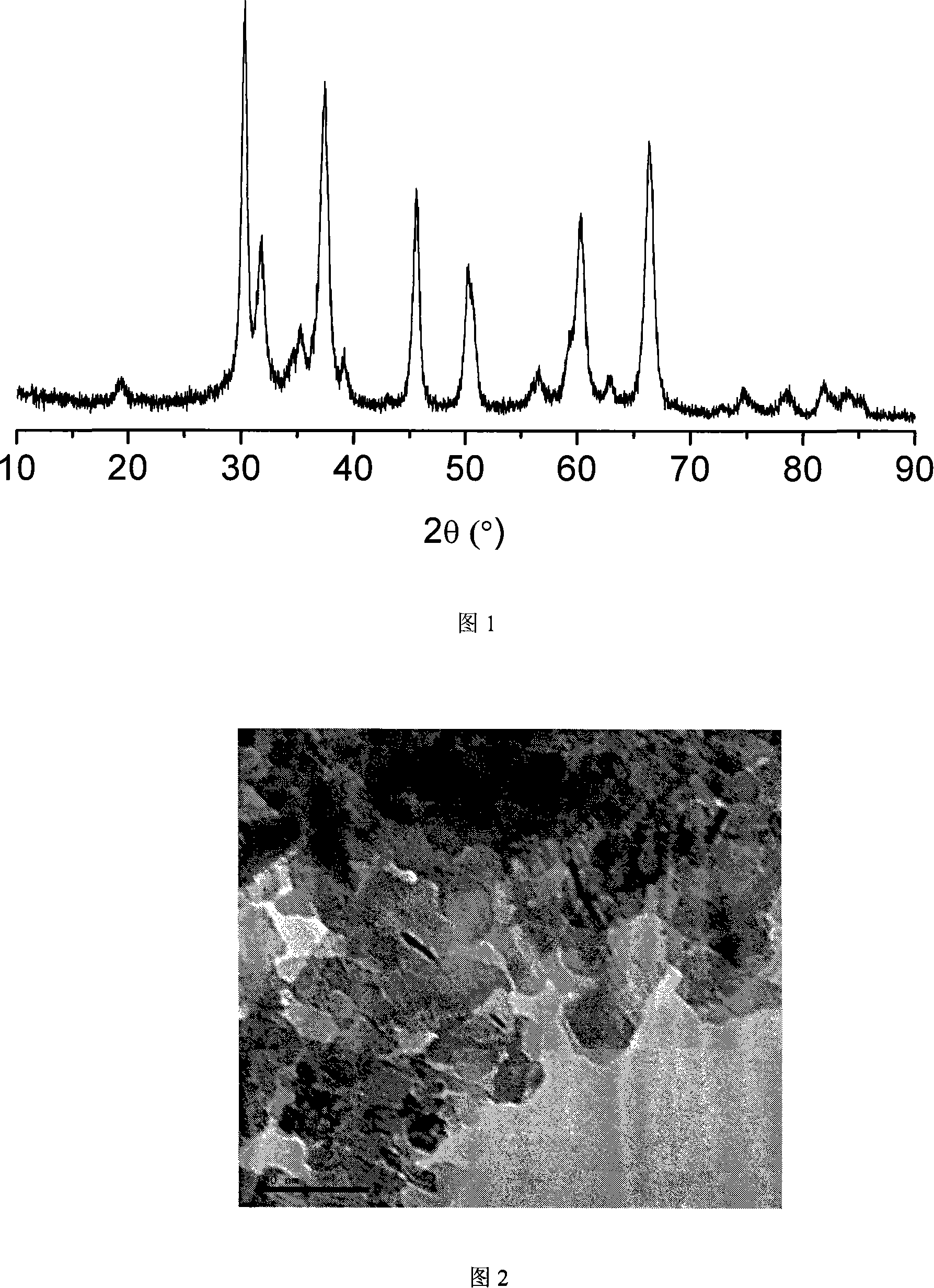

Preparation method of zirconium manganese doped hexa- aluminate catalyzer

A hexaaluminate and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price, restrict the development of precious metal catalysts, etc., and achieve low cost, high temperature stability, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The inverse microemulsion is mixed by 50% cyclohexane, 16% n-butanol, 20% OP-10 emulsifier and 14% water (volume ratio) and then added in a three-necked flask, stirred at a speed of 600 rpm for 10 hours, Let stand for 12 hours. Prepare 0.4mol / L zirconium nitrate solution, 0.6mol / L manganese nitrate solution, and 2mol / L aluminum nitrate solution. Zirconium nitrate: manganese nitrate: aluminum nitrate is 1: 1.5: 10.5 (molar ratio) after mixing, in 80 ℃ of water baths, add dropwise in the inverse microemulsion with the speed of 0.5d / s, the amount of adding polyethylene glycol is 4g, Stop the water bath and stirring, and let stand for 1 to 3 hours. Then drop 3 mol / L urea and 5 mol / L ammonia water in a ratio of 1:2 (volume ratio) into the microemulsion system at a rate of 0.5 d / s in a water bath at 80° C. to produce precipitation until the pH is 8. The precipitate was aged for 24 hours, and the precipitate was filtered out. The precipitate was washed with industrial alcoh...

Embodiment 2

[0015] The inverse microemulsion is added in the there-necked flask after mixing 60% cyclohexane, 20% n-butanol, 20% OP-10 emulsifier and 10% water (volume ratio), and stirred for 10 hours at a speed of 600 rev / min. Let stand for 12 hours. Prepare 0.5mol / L zirconium nitrate solution, 1.0mol / L manganese nitrate solution, and 1.5mol / L aluminum nitrate solution. Zirconium nitrate: manganese nitrate: aluminum nitrate is mixed at 1:2:10 (molar ratio) and then added dropwise to the inverse microemulsion in a constant temperature water bath at 80°C at a rate of 0.5d / s, and the amount of polyethylene glycol added is 3g. Stop the water bath and stirring, let stand for 3h. Then drop 3 mol / L urea and 5 mol / L ammonia water in a ratio of 1:1 (volume ratio) into the microemulsion system at a rate of 0.5 d / s in a water bath at 80°C to produce precipitation until the pH is 8.5. The precipitate was aged for 24 hours, and the precipitate was filtered out. The precipitate was washed with indu...

Embodiment 3

[0017] The inverse microemulsion is added in the there-necked flask after mixing 40% cyclohexane, 15% n-butanol, 25% OP-10 emulsifier and 30% water (volume ratio), and stirred for 10 hours at a speed of 600 rev / min. Let stand for 12 hours. Prepare 0.5mol / L zirconium nitrate solution, 1.0mol / L manganese nitrate solution, and 1.5mol / L aluminum nitrate solution. Zirconium nitrate: manganese nitrate: aluminum nitrate is mixed at 1:1:12 (molar ratio) and then added dropwise to the inverse microemulsion in a constant temperature water bath at 80°C at a rate of 0.5d / s, and the amount of polyethylene glycol added is 2g. Stop the water bath and stirring, let stand for 2h. Then drop 2 mol / L urea and 3.5 mol / L ammonia water in a ratio of 2:1 (volume ratio) into the microemulsion system at a rate of 0.5 d / s in a water bath at 80°C to produce precipitation until the pH is 10. The precipitate was aged for 24 hours, and the precipitate was filtered out. The precipitate was washed with ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com