Low-temperature sintering hexagonal crystal series soft magnet ferrite

A technology of soft magnetic ferrite and hexagonal ferrite, which is applied in the field of metal materials, can solve the problems of reducing the performance of components and affecting the sintering effect, and achieve the effects of high material performance indicators, wide firing temperature and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, adopts analytically pure Fe 2 o 3 、BaCO 3 、 Bi 2 o 3 , CuO, Co 3 o 4 , ZnO, MgO, MnO 2 , NiO, TiO 2 As the initial raw material, weigh the raw material according to the composition ratio (weight ratio) shown in Table 1, use absolute ethanol as the medium for ball milling and mixing for 24 hours, dry at 75°C, pass through a 200-mesh sieve, and pre-calcine for 4 hours; the obtained powder is ball milled Sieve, granulate, shape, and sinter at 890°C for 4 hours. Ring samples, outer diameter 20mm, inner diameter 10mm, thickness 2.5mm, molding pressure 7MPa; sheet samples, diameter 10mm, thickness 1mm, molding pressure 2MPa. The upper and lower surfaces of the fired flake samples were coated with silver to measure their dielectric constant and resistivity. The magnetic spectrum of the fired ring sample was measured by HP4291B (1M-1GHz) RF impedance analyzer. The performance parameters of the obtained samples are listed in Table 1.

Embodiment 2

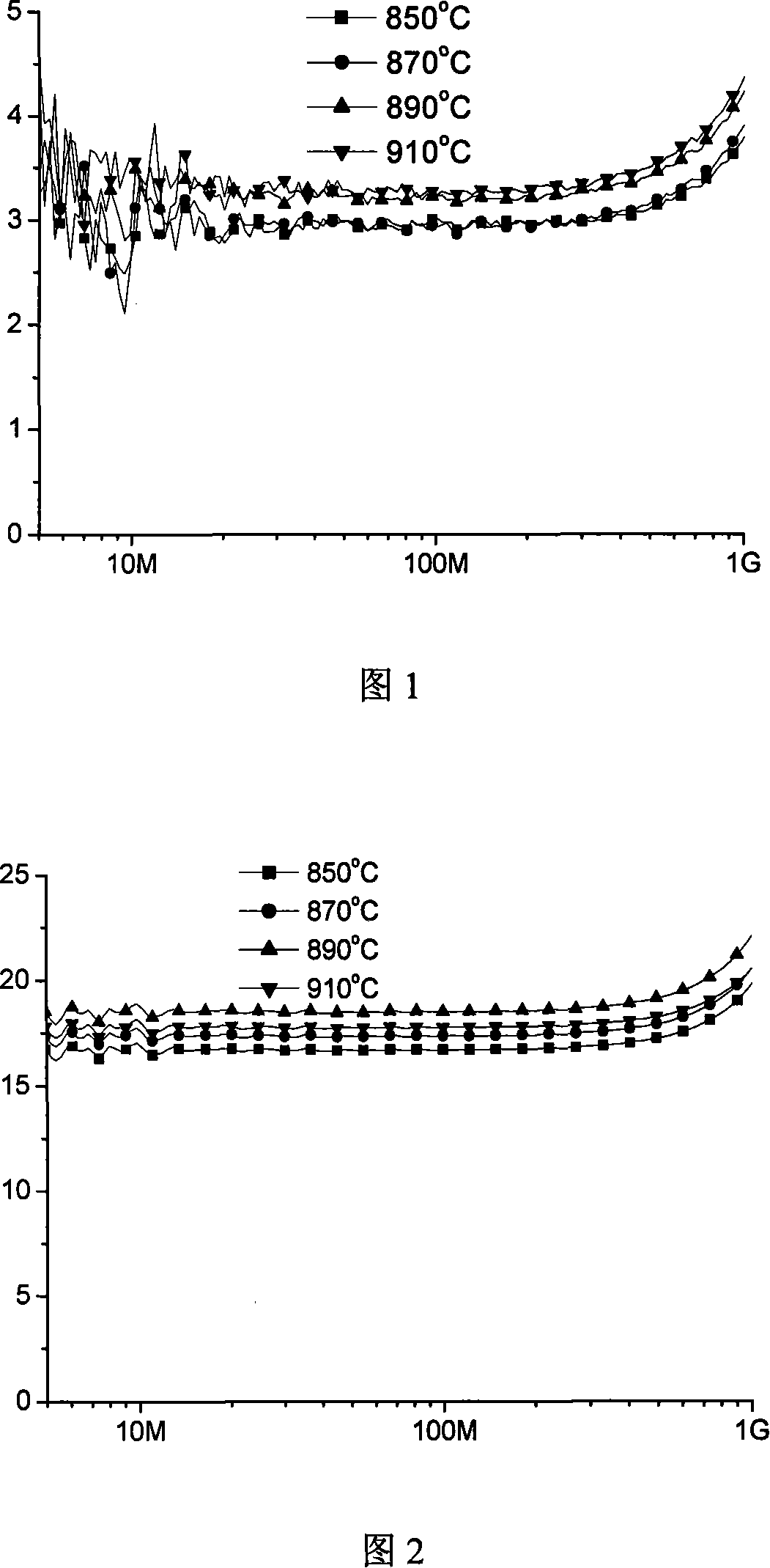

[0013] Embodiment 2, adopt analytically pure Fe 2 o 3 、BaCO 3 、 Bi 2 o 3 , CuO, Co 3 o 4 , ZnO as the initial raw material, by weight ratio Fe 2 o 3 : BaCO 3 : Bi 2 o 3 :CuO:Co 3 o 4 : ZnO=100: 37.7: 4.9: 3.4: 8.5: 6.9 Weigh the raw materials, use absolute ethanol as the medium for ball milling and mixing for 24 hours, dry at 75°C, pass through a 200-mesh sieve, pre-calcine at 900°C, and keep warm for 4 hours to obtain Pure single-phase Y-type hexagonal ferrite powder; ball milling, granulation, molding, sintering at 850°C, 870°C, 890°C, 910°C for 2 hours (denoted as samples 2-1, 2- 2, 2-3 and 2-4). Ring samples, outer diameter 20mm, inner diameter 10mm, thickness 2.5mm, molding pressure 7MPa; sheet samples, diameter 10mm, thickness 1mm, molding pressure 2MPa. The upper and lower surfaces of the fired flake samples were coated with silver to measure their dielectric constant and resistivity. The fired ring sample was measured with HP4291B (1M-1GHz) RF impedance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com