Lead magnesio-niobate-lead titanate binary system high-heat electricity-release ceramic material and preparation technique thereof

A pyroelectric ceramic and lead magnesium niobate technology, which is applied to the lead magnesium niobate-lead titanate binary system high pyroelectric ceramic material and its preparation, and the field of pyroelectric ceramic material and its preparation, which can solve the complex process , less source, high cost, to achieve the effect of simple preparation, convenient raw material processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition formula of lead magnesium niobate (PMN)-lead titanate (PT) binary system is: xPb(Mg 1 / 3 Nb 2 / 3 )O 3 +(1-x)PbTiO 3 , x=0.28, the process of preparing a single-component linear pyroelectric ceramic material with the binary system element of the above-mentioned composition formula is as follows:

[0027] 1) Preparation of MgNb 2 o 6 , that is, in the basic form of MgCO 3 and Nb 2 o 5 reaction, where MgCO 3 and Nb 2 o 5 The feed ratio (molar ratio) is 1:1, the reaction temperature is 950~1020°C, and the reaction time is 2~6 hours;

[0028] 2) Prepare lead magnesium niobate-lead titanate single-component powder, that is, add PbO and TiO according to the chemical formula ratio 2 In the above MgNb 2 o 6 Medium reaction, the reaction conditions are: first react at 680-720°C for 1-3 hours, then react at 820-860°C for 1-3 hours;

[0029] 3) Carry out sintering according to the conventional ceramic material sintering process, the sintering temperature...

Embodiment 2

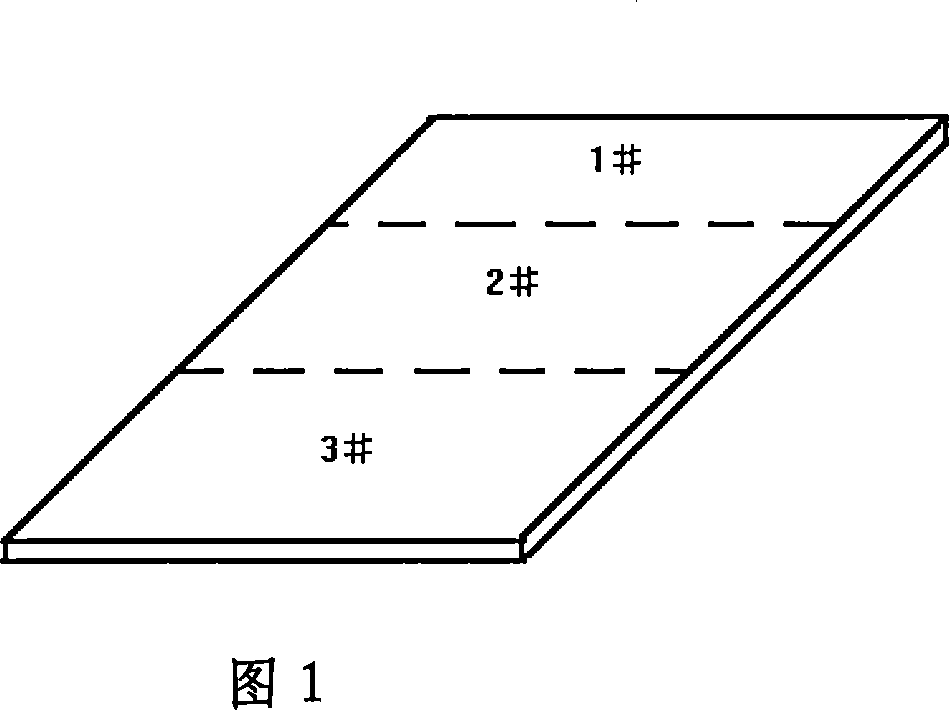

[0033] The composition formulas of lead magnesium niobate (PMN)-lead titanate (PT) binary system elements are: xPb(Mg 1 / 3 Nb 2 / 3 )O 3 +(1-x)PbTiO 3 , x=0.31(1#), 0.33(2#), 0.35(3#), the process of preparing multi-component nonlinear pyroelectric ceramic material with the above-mentioned binary system elements of each composition formula is as follows:

[0034] 1) Preparation of MgNb 2 o 6 , that is, in the basic form of MgCO 3 and Nb 2 o 5 reaction, where MgCO 3 and Nb 2 o 5 The feed ratio (molar ratio) is 1:1, the reaction temperature is 950~1020°C, and the reaction time is 2~6 hours;

[0035] 2) Preparation of lead magnesium niobate-lead titanate component powders, that is, adding PbO and TiO respectively according to the chemical formula ratio 2 In the above MgNb 2 o 6Medium reaction, the reaction conditions are: first react at 680-720°C for 1-3 hours, then react at 820-860°C for 1-3 hours;

[0036] 3) Place the spacer in the mold first, fill the above-mention...

Embodiment 3

[0041] The composition formula of lead magnesium niobate (PMN)-lead titanate (PT) binary system is: xPb(Mg 1 / 3 Nb 2 / 3 )O 3 +(1-x)PbTiO 3 , x=0.25, wherein the doping element is Mn (in the form of MnO), and the doping amount is 0.5wt% MnO, a process for preparing a single-component linear pyroelectric ceramic material with the doped binary system element of the above composition formula as follows:

[0042] 1) Preparation of MgNb 2 o 6 , that is, in the basic form of MgCO 3 and Nb 2 o 5 reaction, where MgCO 3 and Nb 2 o 5 The feed ratio (molar ratio) is 1:1, the reaction temperature is 950~1020°C, and the reaction time is 2~6 hours;

[0043] 2) Prepare lead magnesium niobate-lead titanate single-component powder, that is, add PbO and TiO according to the chemical formula ratio 2 and MnO 2 with the above MgNb 2 o 6 Medium reaction, the reaction conditions are: first react at 680-720°C for 1-3 hours, then react at 820-860°C for 1-3 hours;

[0044] 3) Carry out sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com