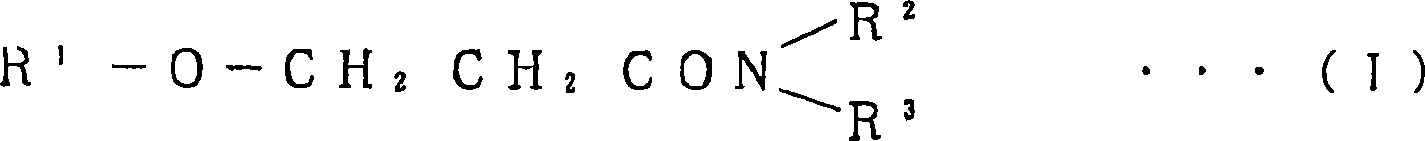

Beta-alkoxypropionamide compound, solvent, detergent, liquid pharmaceutical composition, and process for producing beta-alkoxypropionamide compound

A technology for alkoxypropionamides and medicines, applied in the fields of solvents, detergents and liquid pharmaceutical compositions, beta-alkoxypropionamides, and can solve the problems of rapid disappearance of effects, application limitations and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

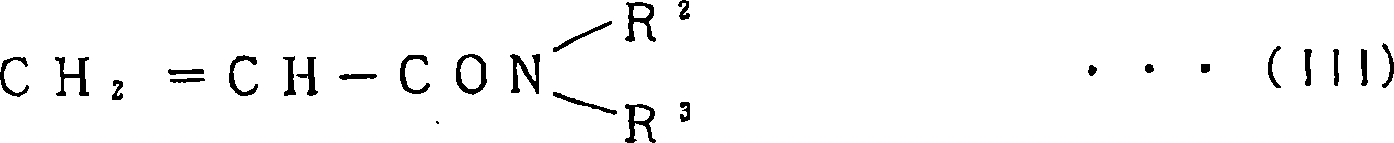

[0049]Another raw material in the preparation method of the present invention is an aliphatic monohydric alcohol with 5 to 18 carbon atoms, R in the above general formula (IV) 5 An alkyl group having 5 to 18 carbon atoms is formed. The aliphatic monohydric alcohol may be linear or branched, and specific examples thereof include n-pentanol, hexanol, octanol, 2-ethylhexanol, decyl alcohol, and lauryl alcohol.

[0050] When the β-alkoxypropionamides in the present invention are used in the form of a mixture as a solvent or a detergent, the mixture can be prepared during the reaction. At this time, the above-mentioned acrylamides as raw materials may be used in combination of at least two kinds; the above-mentioned aliphatic monohydric alcohols may be used in combination of at least two kinds; these two forms may also be used.

[0051] The use ratio of acrylamide and aliphatic monohydric alcohol is preferably stoichiometric or excessive, but it is generally disadvantageous in ter...

Embodiment 1

[0066] 19.828 g of N,N-dimethylacrylamide and 20.434 g of 1-hexanol were put into a 300 mL separable flask equipped with a stirring device, a thermocouple, and a nitrogen gas introduction tube, and stirred while introducing nitrogen gas. Then, 0.338 g of sodium tert-butoxide was added and reacted at 35° C. for 4 hours. After heating, 150 mg of phosphoric acid was added to make the solution uniform, and then left to stand for 3 hours. The solution was filtered to remove precipitates, and unreacted materials were further removed by an evaporator. The yield was 37.4 g (yield 93%).

[0067] determination of the resulting substance 1 As a result of H-NMR, 0.95 ppm (3H), 1.3-1.5 ppm (8H), 2.4 ppm (2H), 2.9 ppm (6H), 3.4 ppm (2H) and 3.7 ppm (2H) were observed. As a result, the following structure was found. A solubility test of the compound was performed. The results are shown in Table 1.

[0068] 【Compound 9】

[0069]

Embodiment 2

[0071] 19.828 g of N,N-dimethylacrylamide and 14.824 g of 1-butanol were put into a 300 mL separable flask equipped with a stirring device, a thermocouple, and a nitrogen gas introduction tube, and stirred while introducing nitrogen gas. Then, 0.338 g of sodium tert-butoxide was added and reacted at 35° C. for 4 hours. After heating, 150 mg of phosphoric acid was added to make the solution uniform, and then left to stand for 3 hours. The solution was filtered to remove precipitates, and unreacted materials were further removed by an evaporator. The yield was 30.5 g (yield 88%).

[0072] determination of the resulting substance 1 As a result of H-NMR, 0.95 ppm (3H), 1.3-1.5 ppm (4H), 2.4 ppm (2H), 2.9 ppm (6H), 3.4 ppm (2H) and 3.7 ppm (2H) were observed. As a result, the following structure was found. A solubility test of the compound was performed. The results are shown in Table 1.

[0073] 【Compound 10】

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com