Method for restraining edge breakdown of avalanche photodiode

An avalanche photoelectric and diode technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as difficulty, limit chip size, and complex implementation, and achieve the goal of suppressing and preventing edge breakdown Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

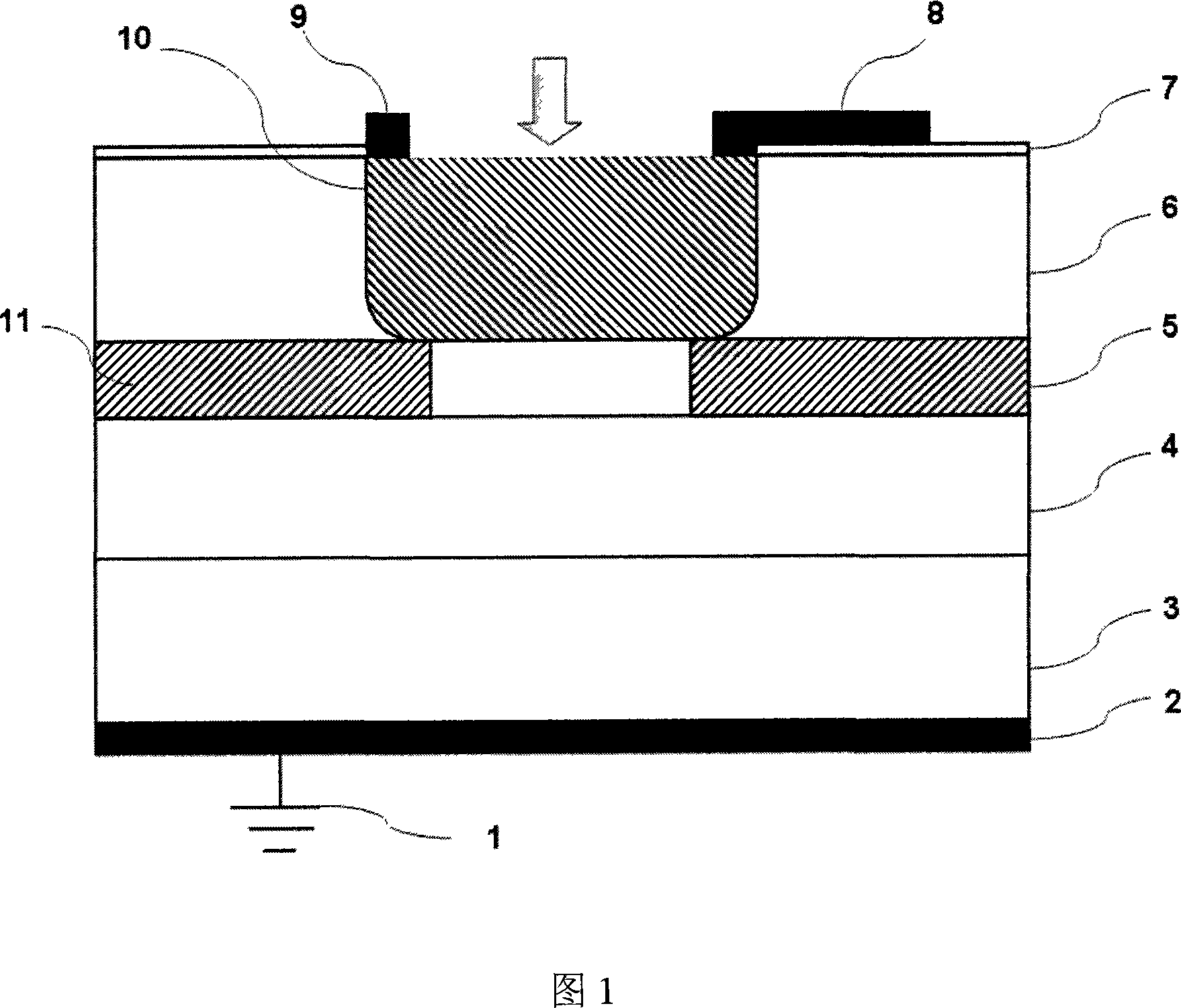

Embodiment 1

[0029] As shown in Figure 2, the APD structure with front light incident, the substrate 3 is GaAs material (gallium arsenide), the absorption layer 4 is GaInNAs material (gallium indium nitrogen arsenide), and the multiplication layer 5 is AlGaAs material (aluminum gallium arsenide) , The intrinsic substrate layer 6 is GaAs material. Choosing GaInAs material for the absorption layer 4 can control the width of the bandgap by adjusting the composition of In and N so that the wavelength of the absorbed light falls in the optical communication band; choosing AlGaAs material for the multiplication layer 5 can effectively control the multiplication noise. In the process of process realization, firstly, the GaInNAs absorption layer 4, the AlGaAs (x>0.8) multiplication layer 5 with high aluminum composition and the intrinsic substrate layer 6 can be grown sequentially on the N-type GaAs substrate 3 by MOCVD, and then by diffusion A P-type heavily doped region 10 is formed on the intri...

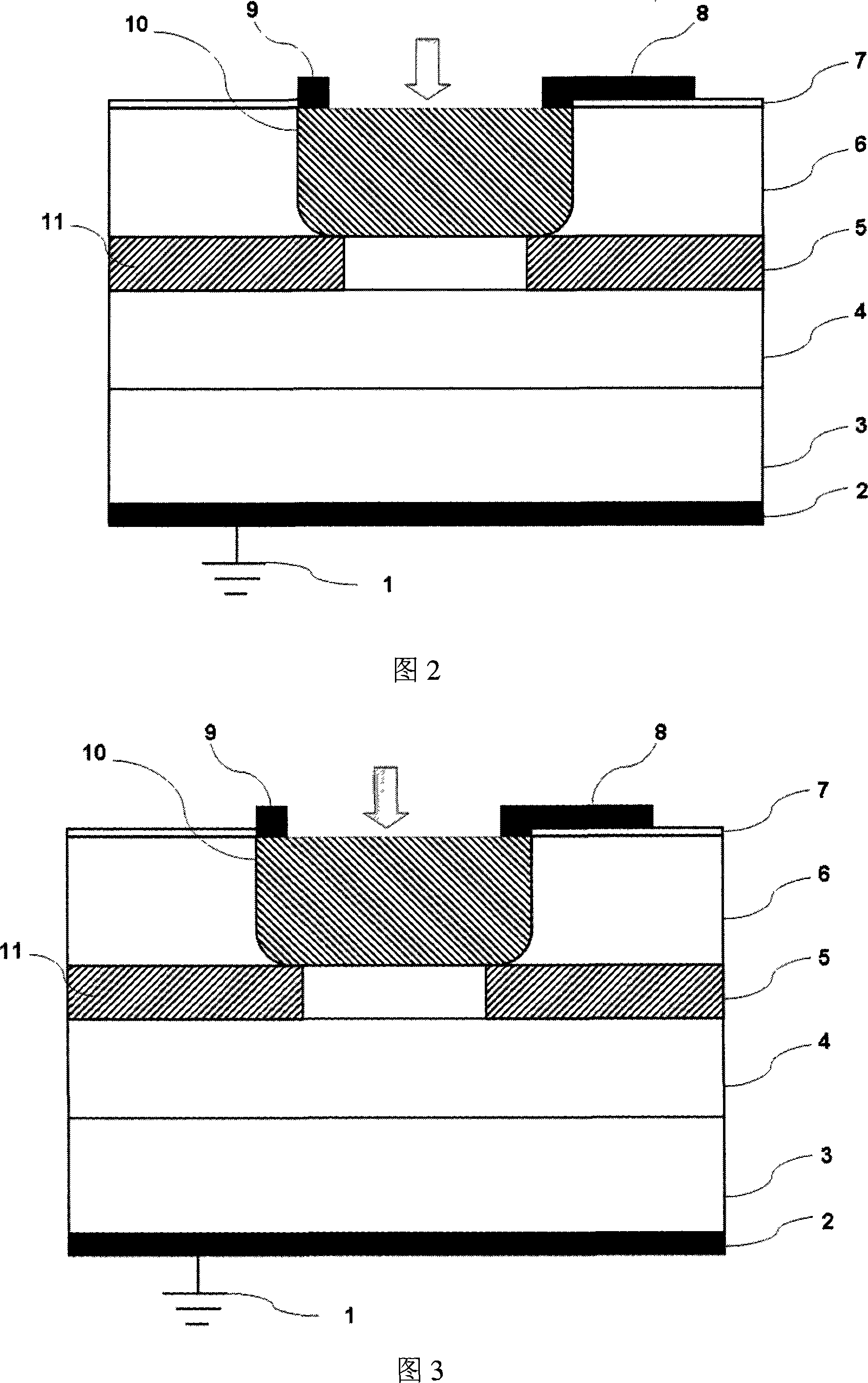

Embodiment 2

[0031] Figure 3 shows the APD structure with front light incident, the substrate 3 is made of InP material (indium phosphide), the absorption layer 4 is made of GaInAs material, the multiplication layer 5 is made of GaAlInAs material, and the intrinsic substrate layer 6 is made of InP material. Since the InGaAs material matched with InP absorbs in the optical communication band, and its SCAM structure has good bandwidth characteristics, it is widely used in optical communication systems. The process of technological realization is identical with embodiment 1.

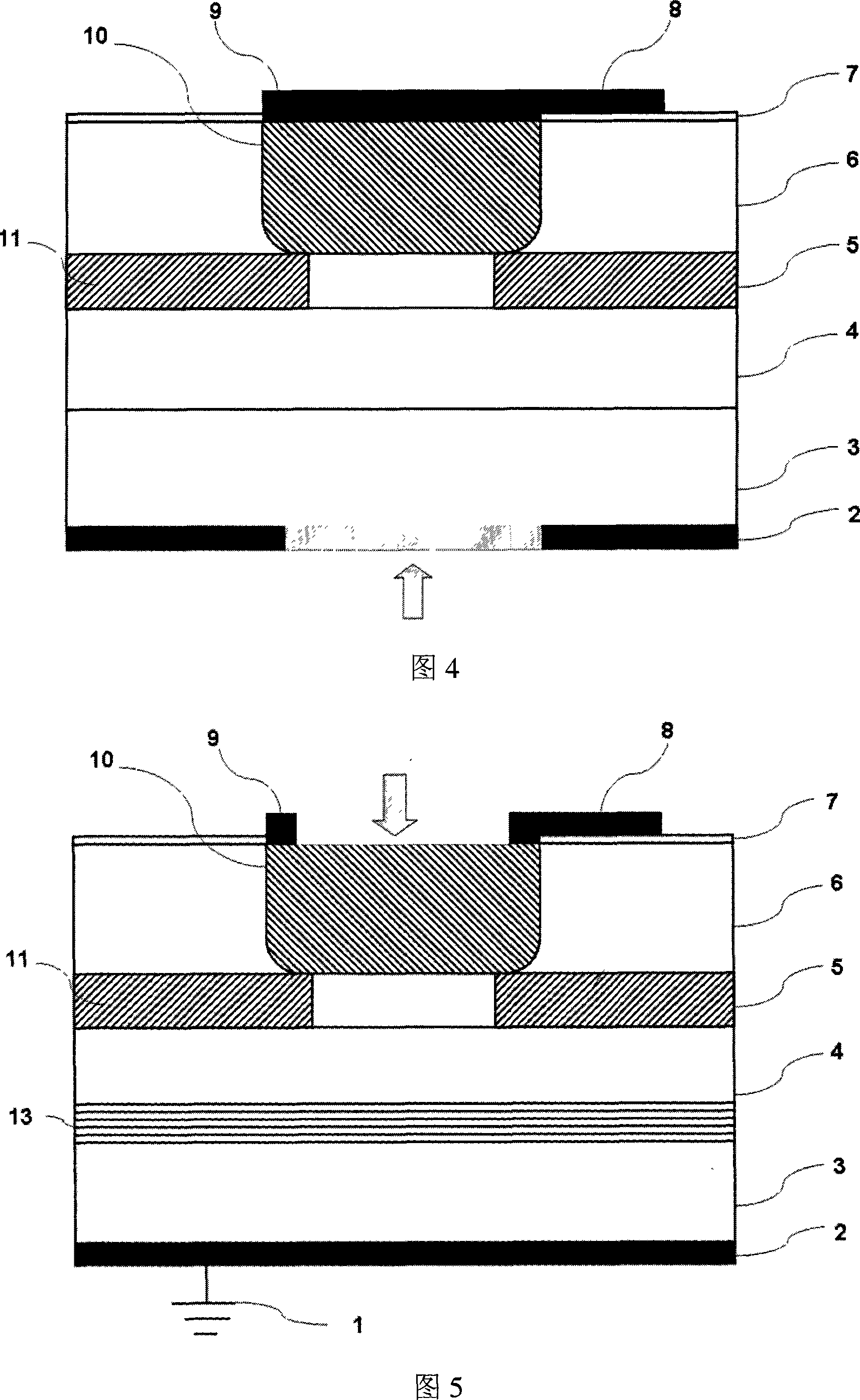

Embodiment 3

[0033] Figure 4 shows the APD structure with back light incident, the substrate 3 is made of GaAs material, the absorption layer 4 is made of GaInNAs material, the multiplication layer 5 is made of AlGaAs material, and the intrinsic substrate layer 6 is made of GaAs material. The manufacture of the main structure in terms of technology is the same as that of Embodiment 1, the difference lies in the manufacture of electrodes. In this embodiment, the P-type electrode 8 and the P-type electrode 9 are directly fabricated on the P-type heavily doped region 10. When fabricating the N-type electrode 2, a substrate 3 is etched on the substrate 3 by semiconductor photolithography to receive incident light. window, and evaporate an anti-reflection metal film, and finally make an N-type electrode 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com