Light solidifying composition and burned object pattern obtained using the same

A technology of photocurability and composition, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment. It can solve the problems of discoloration of glass substrates, difficult oxidation of silver powder, etc., and achieve the effect of reducing yellowing of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

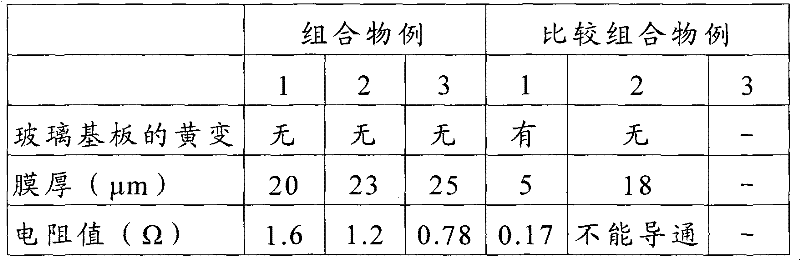

[0043] Hereinafter, the present invention will be specifically described based on examples, but of course, the present invention is not limited to the following examples. In addition, "parts" in the following description mean parts by mass unless otherwise specified.

[0044] The components shown in Composition Examples 1 to 5 and Comparative Composition Examples 1 to 2 below were blended in respective composition ratios, stirred with a mixer, kneaded with a three-roll mill, and formed into a paste.

[0045] - Solder alloy powder: A powder having an alloy composition ratio (mass %) of 96.5% of tin, 3% of silver, and 0.5% of copper was used. The average particle diameter of this alloy powder is the average particle diameter measured using the particle size distribution measuring apparatus by the laser analysis diffraction method, (D50)=12 micrometers, (D10)=9.5 micrometers, (D90)=15.43 micrometers. In addition, the average particle diameter of 10 randomly selected particles ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com