LED light-emitting component

A technology of light-emitting elements and light-emitting wafers, applied to semiconductor devices of light-emitting elements, optical elements for changing the spectral characteristics of emitted light, light sources, etc., can solve the problem of changing spatial light intensity distribution and color temperature Ra value, changing color parameters, Edge color cast and other problems, to avoid high temperature heating, uniform light color rendering, reduced light attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

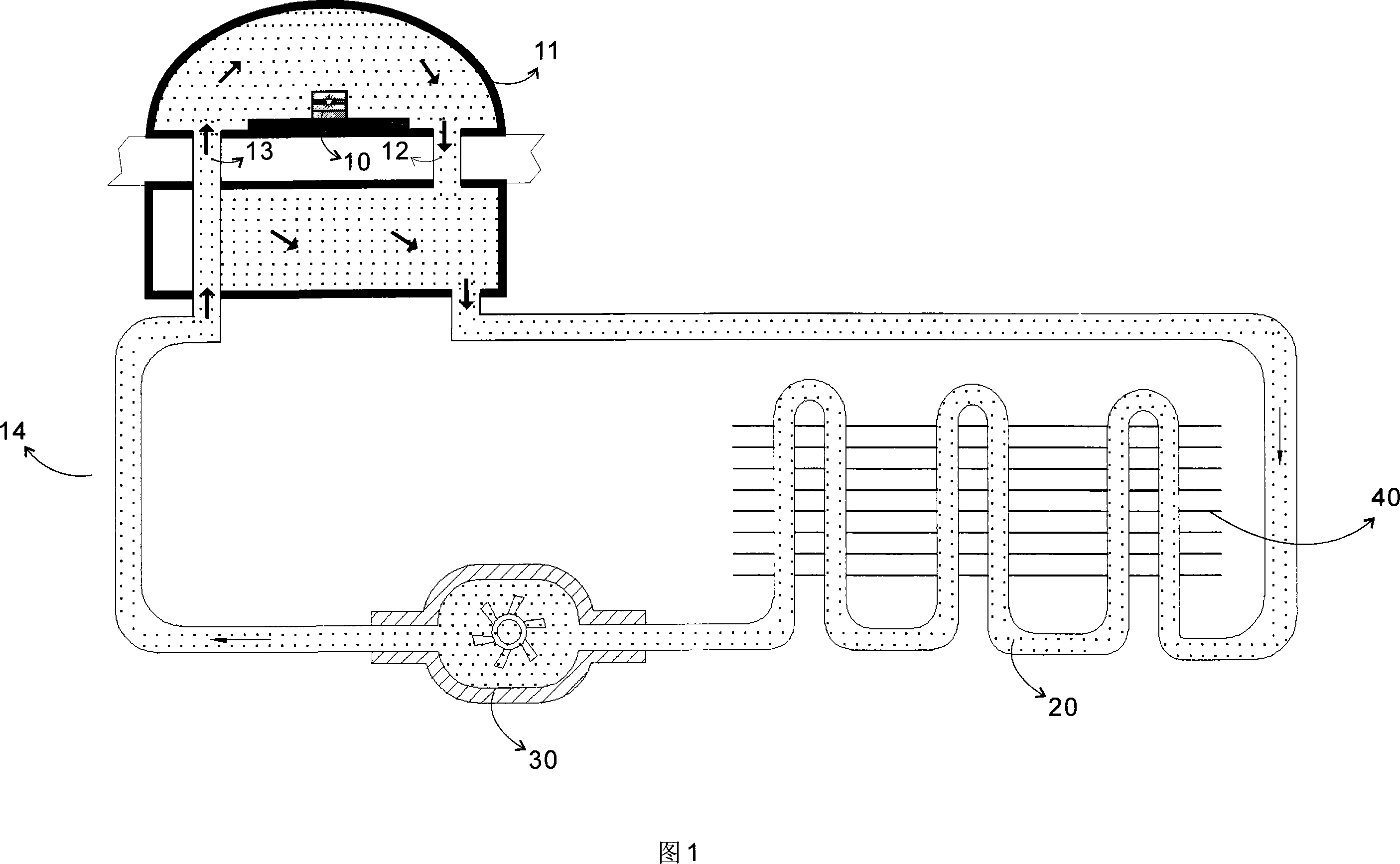

[0017] As shown in FIG. 1 , an LED light-emitting element is provided with an LED light-emitting chip 10 mounted on a metal substrate in a transparent cover 11 . The transparent cover 11 preferably adopts an outer contour with optical characteristics. The transparent cover 11 is provided with flow liquid circulation inlets and outlets 12, 13, and the flow liquid circulation inlets and outlets 12, 13 are preferably arranged on the bottom surface of the transparent cover 11 to form a sealed space. Connect a liquid cooling circulation cooling device 14 at the inlet and outlet 12 and 13 of the flowing liquid circulation, fill the transparent cover 11 with liquid through the liquid cooling circulation cooling device 14, and make the liquid cover the LED light emitting chip 10 surface. Phosphor powder is added to the liquid, so that the phosphor powder is uniformly dispersed in the liquid on the surface of the LED light-emitting chip 10 , wherein the flowing liquid containing the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com