Biofermentation method of foodstuff garbage

A technology for food waste and biological fermentation, applied in the field of biological fermentation of waste, can solve the problems of increasing production cost of commercial enzyme preparations, effective utilization of difficult-to-product fermentation production strains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

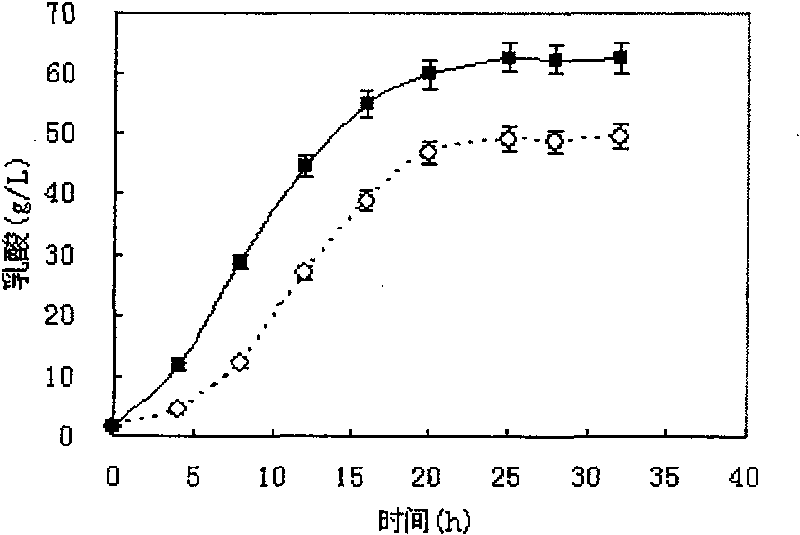

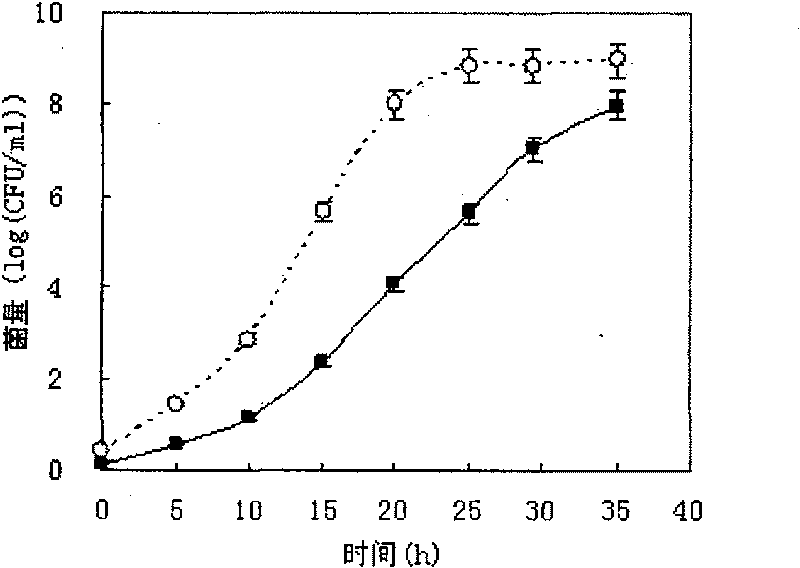

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the food waste of this embodiment is biologically fermented according to the following steps: (1) filter the food waste and inoculate Aspergillus niger, then prepare saccharification enzyme koji by solid-state fermentation under the condition of 30~35° C. for 5~6 days; (2) ) adding saccharifying enzyme koji and biological fermentation strains to fresh food waste, and adding tap water of the same quality as fresh food waste to ferment; (3) separating and purifying to obtain the fermentation product.

[0009] The saccharification enzyme koji prepared in step (1) of this embodiment can be used directly without drying.

[0010] This embodiment can be used for fermentative production of organic acids, alcohols, hydrogen and methane, and biological fermentation strains and fermentation conditions can be selected according to the required fermentation products, and existing conventional methods can be used for the separation and purification of fermenta...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step (1), after the food waste is filtered dry, it is first crushed into a volume less than 1.5cm 3 particle. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in the step (1), press the 7%~9% inoculation concentration of food waste quality after filtering to be 10 6 ~10 7 Spores / mL of Aspergillus niger spore suspension. Other steps and parameters are the same as those in Embodiment 1.

[0013] The saccharifying enzyme koji prepared in this embodiment has not been dried and purified, and its saccharifying enzyme activity is 3500-4500 U / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com