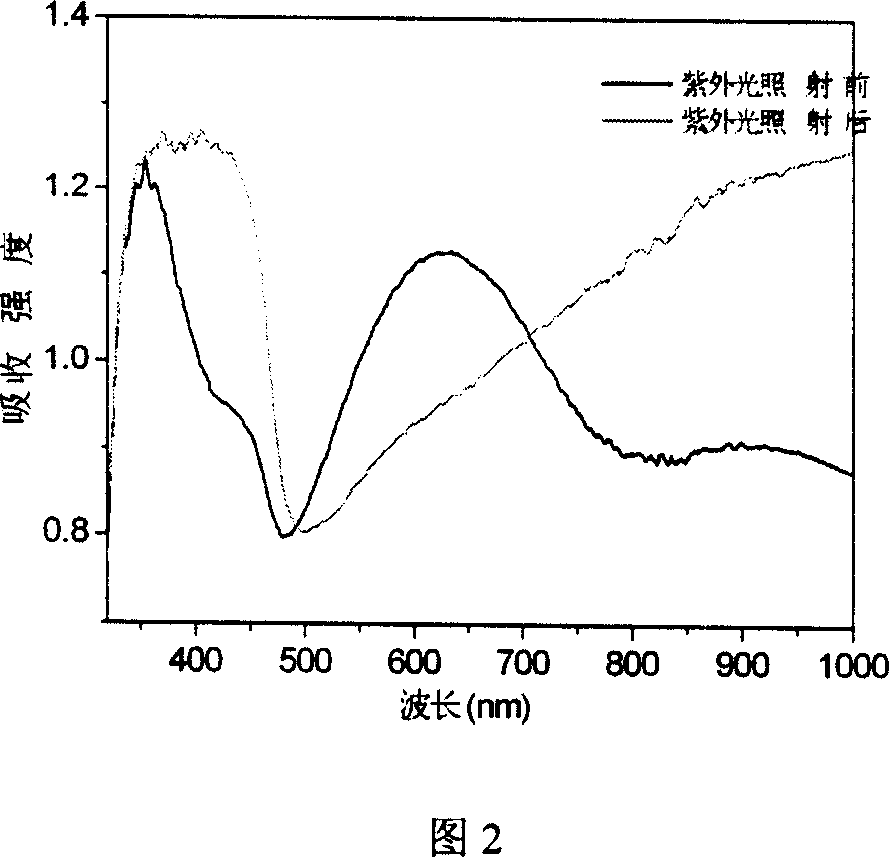

High obstructive polyaniline composite film and its preparation method and use

A high-barrier, composite film technology, applied in the field of functional materials, can solve the problems of insufficient strength of modified polyaniline and affect the conductivity, etc., and achieve the effects of low cost, good repeatability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) 3 g of polyaniline in intrinsic state was dissolved in 100 g of chloroform, stirred for 12 hours, and the insoluble matter was filtered off to obtain a solution of polyaniline in intrinsic state;

[0050] 2) 3 g of vinylidene chloride-acrylonitrile copolymer (copolymerization ratio 9:1) was dissolved in 5 g of chloroform to obtain the copolymer solution;

[0051] 3) Add 10 g of the intrinsic polyaniline solution obtained in step 1) to the polyvinylidene chloride copolymer solution obtained in step 2), and mix evenly to obtain a uniform intrinsic polyaniline mixed solution;

[0052] 4) Put the intrinsic state polyaniline mixed solution prepared in step 3) into the liquid supply device of the electrospray device, and the working distance (the distance between the needle tip and the receiving device) is 16 cm; the receiving device is covered with a thin metal aluminum 40cm 2 square printing paper; turn on the high-voltage power supply, adjust the electrospray voltage t...

Embodiment 2

[0063] 1) 3 g of polyaniline in intrinsic state was dissolved in 100 g of N,N-dimethylformamide, stirred for 12 hours, and insolubles were filtered off to obtain polyaniline in intrinsic state;

[0064] 2) 3 g of vinylidene chloride-methyl acrylate copolymer (copolymerization ratio 9:1) was dissolved in 5 g of N,N-dimethylformamide to obtain the copolymer solution;

[0065] 3) Add 10 g of the intrinsic polyaniline solution obtained in step 1) to the polyvinylidene chloride copolymer solution obtained in step 2), and mix evenly to obtain a uniform intrinsic polyaniline mixed solution;

[0066] 4) Put the intrinsic state polyaniline mixed solution prepared in step 3) into the liquid supply device of the electrospray device, and the working distance (the distance between the needle tip and the receiving device) is 10 cm; Placed carrier film; turn on the high-voltage power supply, adjust the electrospray voltage to 10kV, and the conductive polyaniline mixture is sprayed from the s...

Embodiment 3

[0070] 1) 3 g of polyaniline in intrinsic state was dissolved in 100 g of N,N-dimethylformamide, stirred for 12 hours, and insolubles were filtered off to obtain polyaniline in intrinsic state;

[0071] 2) 1 g of vinylidene chloride-vinyl acetate copolymer (copolymerization ratio 9:1) was dissolved in 10 g of N,N-dimethylformamide to obtain the copolymer solution;

[0072] 3) Add 5 g of the intrinsic polyaniline solution obtained in step 1) to the polyvinylidene chloride copolymer solution obtained in step 2), and mix evenly to obtain a uniform intrinsic polyaniline mixed solution;

[0073] 4) Put the intrinsic state polyaniline mixed solution prepared in step 3) into the liquid supply device of the electrospray device, and the working distance (the distance between the needle tip and the receiving device) is 8 cm; the receiving device is placed on a metal aluminum sheet cotton fiber fabric; turn on the high-voltage power supply, adjust the electrospray voltage to 12kV, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com