System and method for detoxifying boiler flyash re-melt soldering slag

A fly ash and boiler technology is applied in the system field of chromium slag detoxification treatment by boiler fly ash remelting method. problem, to achieve the effect of improving combustion efficiency and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

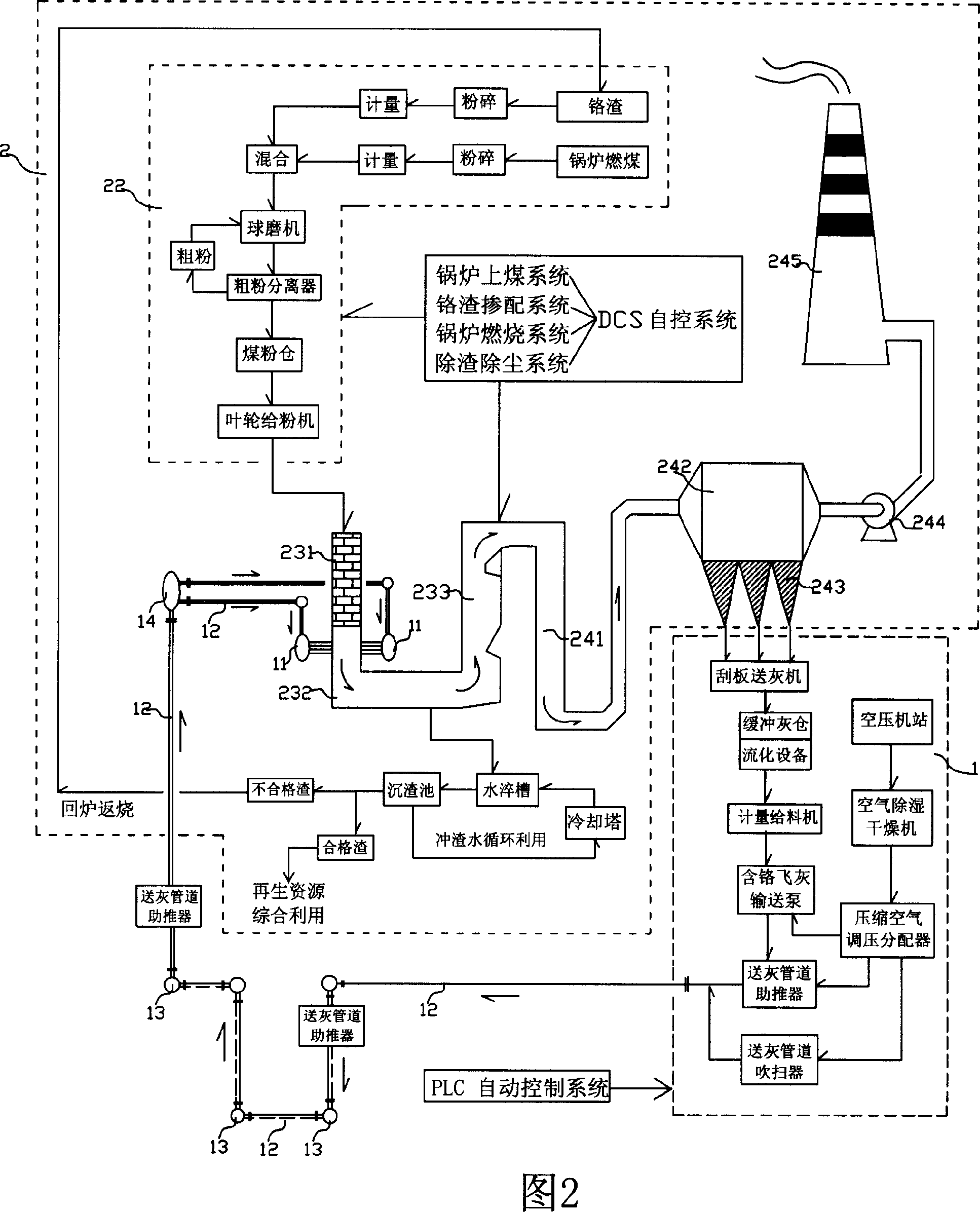

[0030] As shown in Figure 2, in the present embodiment, mainly taking the cyclone furnace as an example, the chromium slag detoxification treatment system and method thereof of the present invention are as follows:

[0031] The boiler fly ash remelting chromium slag detoxification system of the present invention includes a boiler system 1 and a fly ash remelting system 2. system and ash and slag removal system, the boiler system also includes a tail electrostatic precipitator 242, the fly ash remelting system has at least one high-pressure fly ash injector 11 with compressed air as the carrier, and the high-pressure fly ash injection The ash inlet of the device 11 is connected with the outlet of the electrostatic precipitator 242 at the boiler tail, and the ash delivery outlet of the high-pressure fly ash injector 11 is connected with the boiler slag section 232 in the high temperature zone of the boiler combustion system. The high-pressure fly ash injector 11 is a high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com