Outside cycle continuous biological aerated filter for composite fillers

A technology of biological aerated filter and composite filler, applied in the field of continuous biological aerated filter with external circulation of composite filler, which can solve problems such as blockage, reduced oxygen transfer rate, unstable effluent quality, etc., to improve treatment efficiency and improve cleaning Effect, enhance the effect of hanging film and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

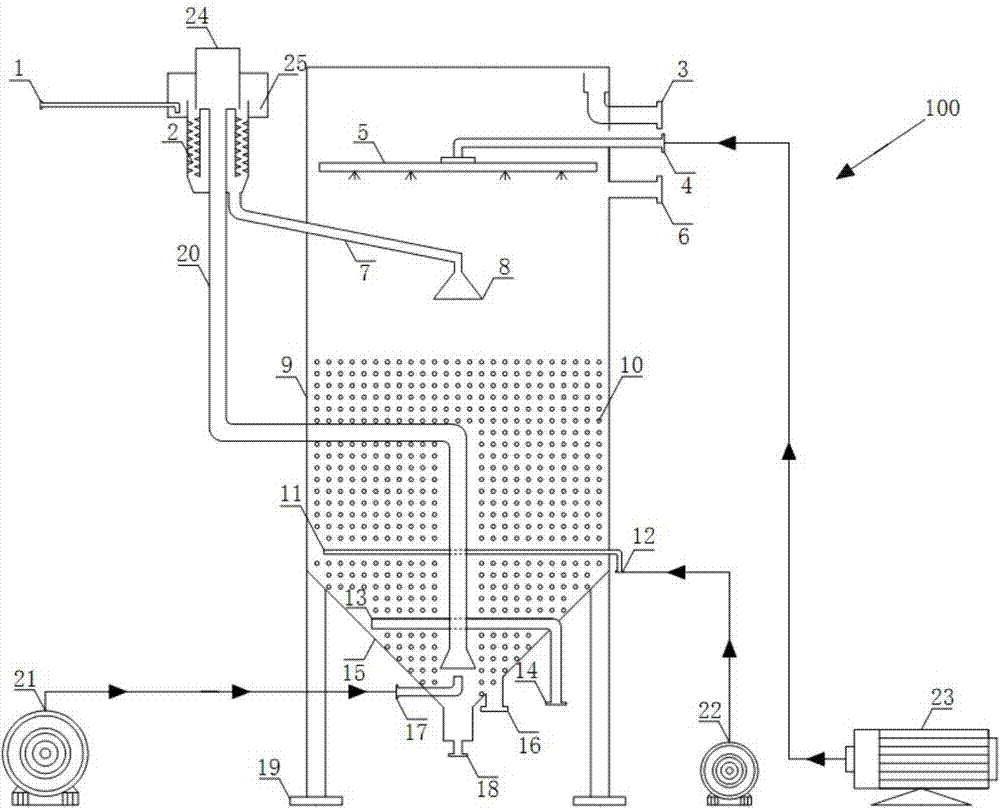

[0018] The biological aerated filter of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] figure 1 It is a schematic cross-sectional structure diagram of the biological aerated filter of the present invention.

[0020] Such as figure 1 As shown, the biological aerated filter 100 of the present invention includes two main parts of the continuous biological aerated filter main body and the packing cleaning part. Among them, the packing cleaning part includes a compressed air supply unit, a compressed air lift pipe 2, a compressed air lifting pipe protective cover 24, a packing cleaning unit includes a packing self-cleaning device 2, and a cleaning waste water discharge unit includes a waste water catchment area 25 and a waste water discharge pipe 1 , The filler return unit includes a material guide pipe 7 and a material guide cover 8 . Among them, the compressed air supply unit has an air compressor 21 and a compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com