Oil sludge cleaning agent and method for treating oil sludge by using oil sludge cleaning agent

A cleaning agent and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of oil in sludge being difficult to elute, achieve easy degradation, improve sludge cleaning rate, improve The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-efficiency sludge cleaning agent, comprising a soil eluent and an emulsifier; the raw material mass percentage of the soil eluent consists of 3% sodium sulfate, 2.5% limonene, 0.3% citric acid, propylene bis(octadecyl di Methyl ammonium chloride) 1%, water 93.2%; The raw material mass percent of emulsifier is composed of fatty alcohol polyoxyethylene ether (AEO-9) 10%, hydroxyethyl ethylenediamine 20%, sodium carbonate 55%, mouse Li glycolipid 15%.

Embodiment 2

[0027] A high-efficiency sludge cleaning agent, comprising a soil eluent and an emulsifier; the raw material mass percentage of the soil eluent consists of 5% sodium sulfate, 5% limonene, 0.5% oxalic acid, propylene bis(octadecyl dimethyl ammonium chloride) 2%, water 87.5%; the raw material mass percent of emulsifier is composed of fatty alcohol polyoxyethylene ether (AEO-9) 15%, hydroxyethyl ethylenediamine 10%, sodium carbonate 50%, cascara Glycolipids 25%.

Embodiment 3

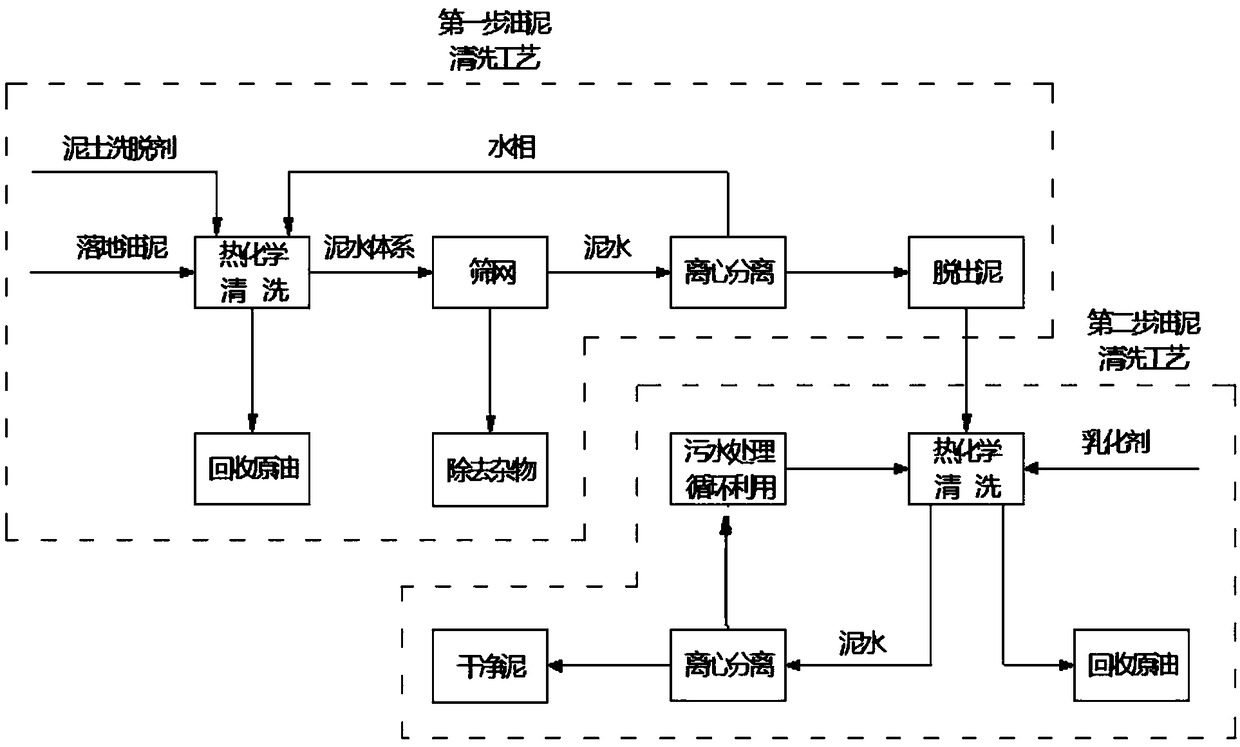

[0029] A method of using the oil sludge cleaning agent of Example 1: in the first cleaning container (cleaning tank) with a mechanical stirring device, add the oil sludge to be treated and the soil eluent at a mass ratio of 1:4, and heat it at a temperature of 75 ° C. , under the condition of stirring speed of 500rpm, after stirring for 0.5-1h, keep it at constant temperature for 0.5-1h, the mixed system is divided into three layers, the upper layer is the crude oil washed out, the middle layer is the water layer, and the lower layer is the muddy water system; take the upper layer of crude oil and To be recovered, the muddy water system is filtered with a screen to remove large-sized stones, organic matter and other sundries in the sludge. The filtered muddy water system is subjected to high-speed centrifugation, and the water phase obtained by centrifugation is transported to the first cleaning tank for recycling. Collect the desorbed sludge in the lower layer after centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com