Synthesis of animal nutrient additive amino-acid-selenomethionine

A technology of selenomethionine and nutritional additives, which is applied in the field of synthesis of selenium-containing amino acid compounds, can solve the problems of harsh reaction conditions, long process route, and high cost, and achieve the effects of mild reaction conditions, good safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

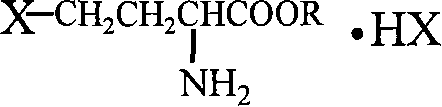

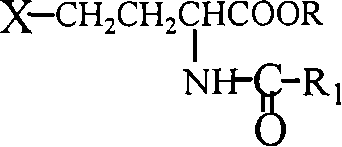

Method used

Image

Examples

Embodiment 1

[0035] Add 50g CH to a 500ml reaction bottle 3 SeSeCH 3 , add 20ml of DMSO to dilute, add 100ml of 6M NaOH aqueous solution under stirring, keep the temperature at 25°C, add a total of 6g of NaBH in batches 4 , fully stirred and reacted for 5 hours to obtain a transparent solution.

[0036] Add 35g of 4-bromo-α-aminobutyric acid methyl hydrobromide to the above obtained solution, raise the temperature to 60°C, stir and react for 3 hours, after the reaction is completed, add 3M hydrochloric acid to acidify, concentrate to dryness, dissolve with ethanol, Filtrate, collect the filtrate, adjust pH=6-7 with ammonia water, filter, wash, and dry to obtain 14.85 g of metallic luster selenomethionine with a yield of 60%, HPLC content analysis of 98%, and selenium content of 38.5%.

Embodiment 2

[0038] Add 150g CH to a 1000ml reaction bottle 3 SeSeCH 3 , add 100ml DMF for dilution, add 300ml concentration of 8M KOH aqueous solution under stirring, keep the temperature at 60°C, add a total of 64.5g of KBH in batches 4 , fully stirred and reacted for 4 hours to obtain a transparent solution.

[0039] Add 135g of methyl 4-chloro-α-(N-acetyl)aminobutyrate to the solution obtained above, raise the temperature to 40°C, stir and react for 8 hours, after the reaction, add 2M hydrochloric acid to acidify, concentrate to dryness, and wash Dissolve, filter, collect the filtrate, adjust pH=6 to 7 with ammonia water, filter, wash, and dry to obtain 75.2 g of metallic luster selenomethionine with a yield of 55%, HPLC content analysis of 97%, and selenium content of 38.0%.

Embodiment 3

[0041] Add 5 g of CH to a 50 ml reaction vial 3 SeSeCH 3 , add 5ml of HMPA to dilute, add 10ml of 1M NaOH aqueous solution under stirring, keep the temperature at 20°C, add a total of 0.6g of NaBH in batches 4 , fully stirred and reacted for 10 hours to obtain a transparent solution.

[0042] Add 7g of 4-bromo-α-aminobutyric acid hydrobromide to the solution obtained above, raise the temperature to 50°C, and stir the reaction for 5 hours. After the reaction, add 3M hydrochloric acid to acidify, concentrate to dryness, dissolve with ethanol, and filter. The filtrate was collected, adjusted to pH=6-7 with ammonia water, filtered, washed, and dried to obtain 3.18 g of metallic luster selenomethionine with a yield of 61%, an HPLC content analysis of 98%, and a selenium content of 38.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com