Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

A technology for water-retaining mining and applicable conditions, applied in ground mining, earth drilling, underground mining, etc., can solve problems such as unsatisfactory water-retaining effect, low recovery rate of coal resources, and hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

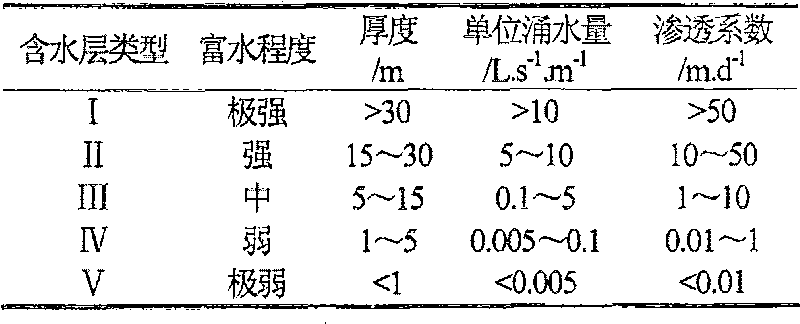

[0012] The method for classifying applicable conditions of water conservation mining of the present invention firstly performs the following steps according to the structural characteristics of shallow buried thin bedrock deposits:

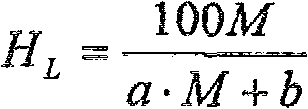

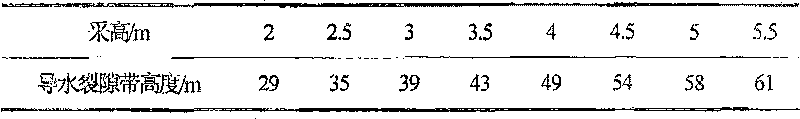

[0013] 1. Prediction of the height of the water-conducting fissure zone, the general calculation formula for the height of the water-conducting fissure zone is:

[0014] H L = 100 M a · M + b or H L =aM+b

[0015] Where: H L —height of fracture zone, m;

[0016] M - mining height, m;

[0017] a, b—coefficients related to mining geological conditions;

[0018] The conventional empirical formula for water-conducting fracture zone is not very suitable for shallow coal seams with thin bedrock. According to the structural characteristics of shallow-buried thin bedrock deposits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com