Ceramic-diaphragm sewater pretreating method

A ceramic membrane and pretreatment technology, which is applied in seawater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of chemical cleaning of polymer membranes that are easy to break, membrane maintenance and replacement, etc. Low permeation flux and other issues, to achieve the effect of reliable technical guarantee, low cost, and increase permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

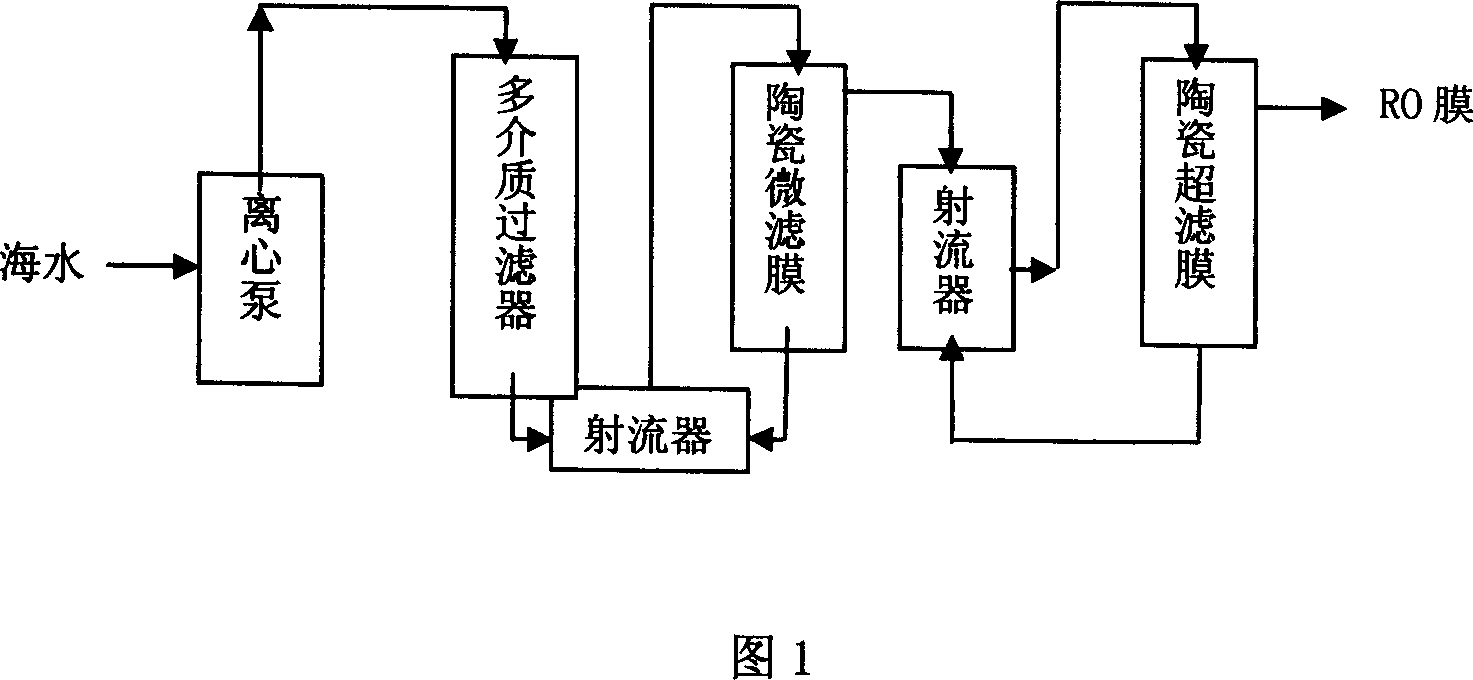

Embodiment 1

[0024] Embodiment 1 The seawater with a turbidity of 5-15 NTU is lifted to the multi-media filter by a centrifugal pump, the inlet pressure of the multi-media filter is 0-0.4 MPa, the outlet water of the multi-media filter enters the ceramic microfiltration membrane filtration unit, and the inlet pressure of the ceramic microfiltration membrane is 0 ~ 0.3MPa, the effluent enters the ceramic ultrafiltration membrane filtration unit, the inlet pressure of the ceramic ultrafiltration membrane is 0 ~ 0.25MPa, and the effluent of the ceramic ultrafiltration membrane feeds the reverse osmosis membrane. Ceramic microfiltration membrane reflux and multi-media filter effluent are mixed by ejector to become ceramic microfiltration membrane influent; ceramic ultrafiltration membrane reflux and ceramic microfiltration membrane effluent are mixed by ejector to be ceramic ultrafiltration membrane influent. The effluent turbidity of the ceramic ultrafiltration membrane is less than 0.3NTU, an...

Embodiment 2

[0025]Example 2 Seawater with a turbidity of 25 to 100 NTU has a turbidity of 5 to 15 NTU after sterilization, flocculation and precipitation, and is lifted to a multi-media filter by a centrifugal pump. The inlet pressure of the multi-media filter is 0 to 0.4 MPa. The outlet water enters the ceramic microfiltration membrane filtration unit, the inlet pressure of the ceramic microfiltration membrane is 0~0.3MPa, the outlet water enters the ceramic ultrafiltration membrane filtration unit, the inlet pressure of the ceramic ultrafiltration membrane is 0~0.28MPa, and the turbidity of the ceramic ultrafiltration membrane outlet water is less than 0.5NTU , SDI2 o 3 , the nominal pore size of the microfiltration membrane is 0.5μm, the nominal pore size of the ceramic ultrafiltration membrane is 100nm, the diameter of the membrane tube is 31mm, and the shape is a 7-channel circular tube. The number of membrane elements in each membrane shell is 7 membrane cores. The length of the mem...

Embodiment 3

[0026] Example 3 Seawater with a turbidity of 25 to 100 NTU, after sterilization, flocculation and sedimentation, has a turbidity of 5 to 15 NTU, and flows into the multi-media filter based on the potential difference, and the effluent of the filter enters the intermediate water tank, and the effluent of the intermediate water tank is lifted by a centrifugal pump to enter Ceramic microfiltration membrane filtration unit, ceramic microfiltration membrane inlet pressure 0 ~ 0.3MPa, effluent water enters ceramic ultrafiltration membrane filtration unit, ceramic ultrafiltration membrane inlet pressure 0 ~ 0.28MPa, ceramic ultrafiltration membrane effluent turbidity 2 o 3 , the nominal pore size of the microfiltration membrane is 0.2μm, the nominal pore size of the ceramic ultrafiltration membrane is 30nm, the diameter of the membrane tube is 30mm, and the shape is a 19-channel circular tube. The number of membrane elements in each membrane shell is 19 membrane cores. The length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Nominal aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com