Mesoporous CuO/Ce0.8Zr0.2O2 catalyst preparation and use of same in oxidation of CO

A catalyst and mesoporous technology, which is applied in the field of inorganic nano-catalytic materials, can solve the problems of cumbersome process, unsatisfactory low-temperature oxidation activity of catalytic CO, high toxicity of raw materials, etc., and achieve simple preparation process and equipment, good industrial production prospects, large The effect of industrial application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

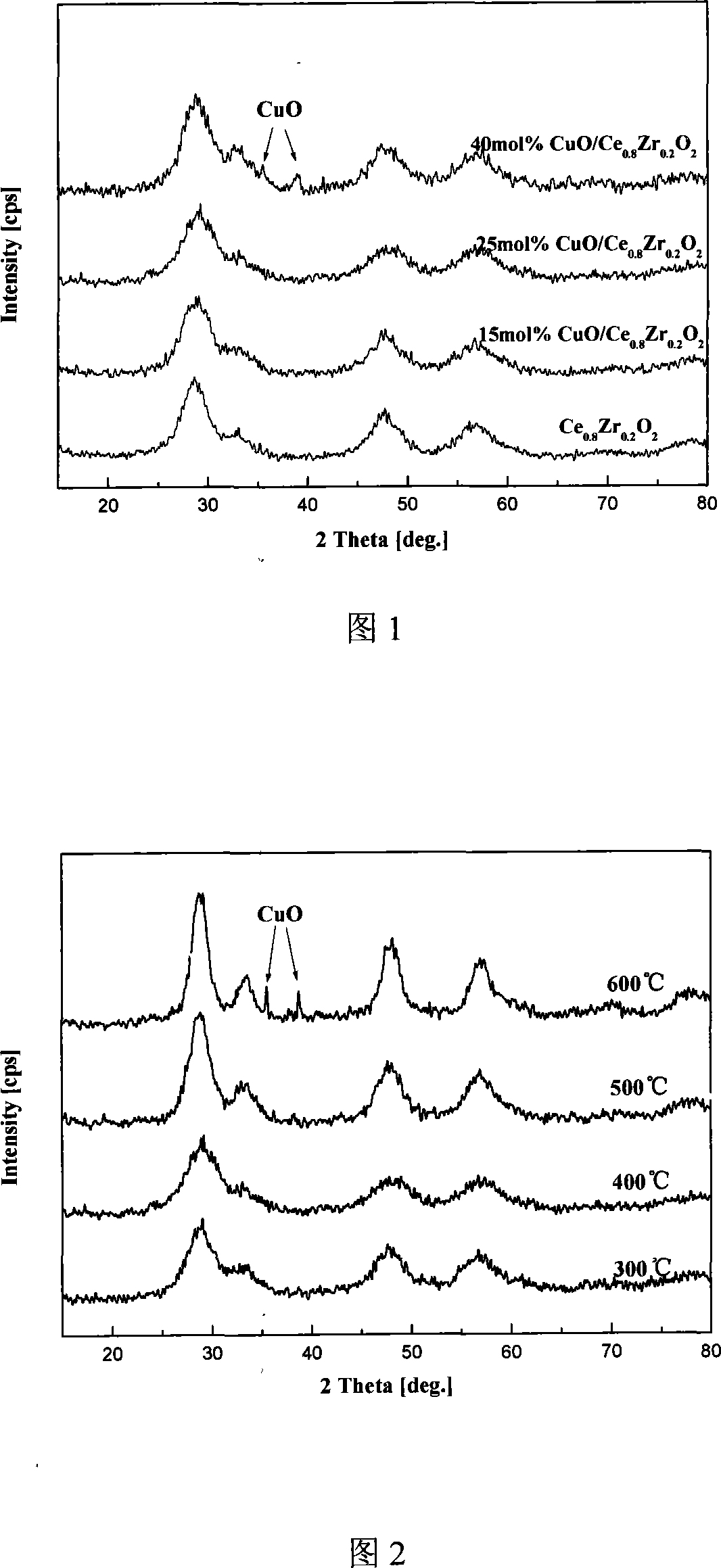

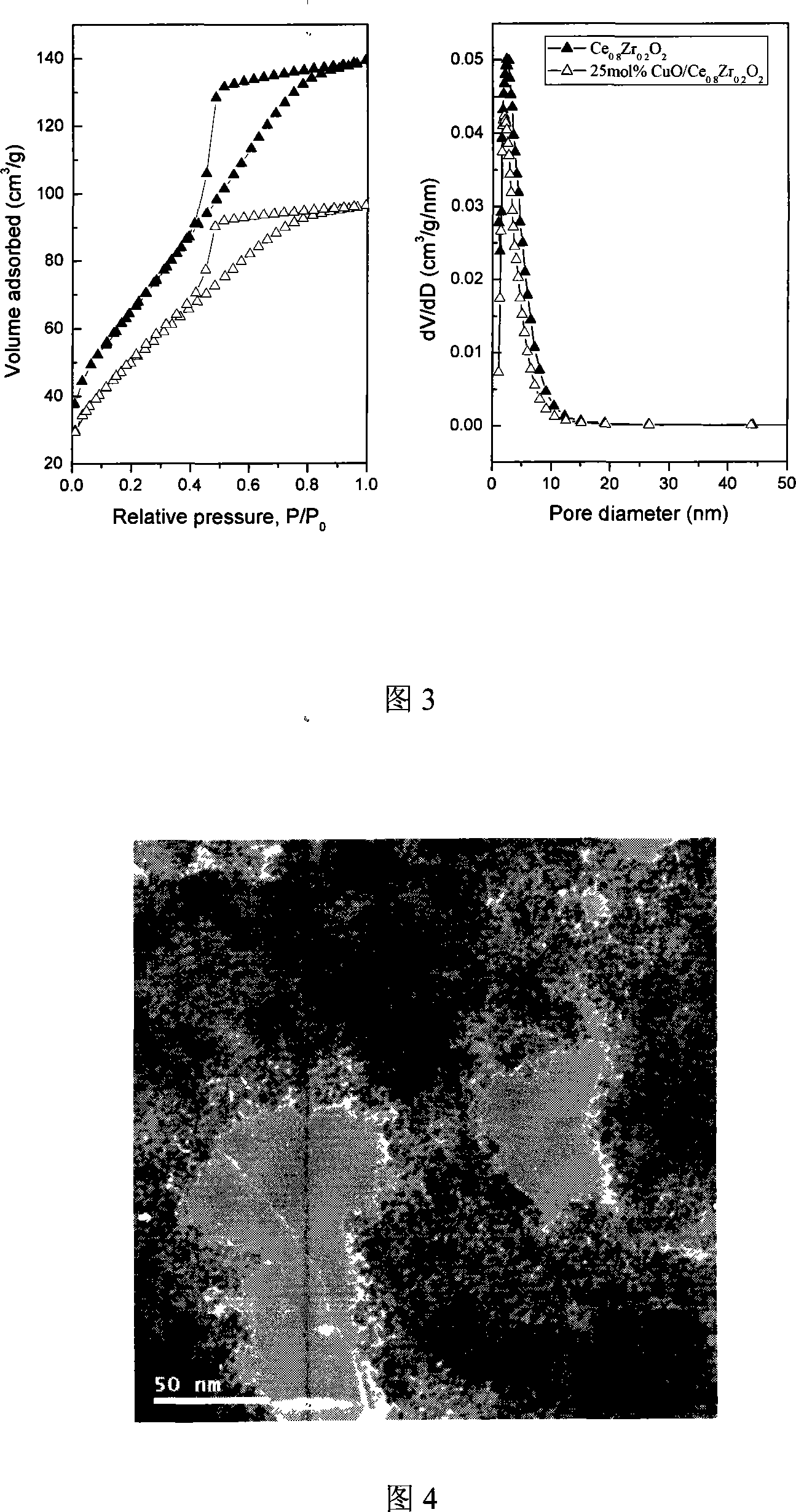

[0026] At room temperature, weigh 6 mmol of CTAB, dissolve it in 200 mL of deionized water, and disperse for 15 minutes. Add the calculated amount of Ce(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O (molar ratio 4:1), continue to stir for 30 minutes, add 0.2M NaOH solution to pH 10, stir the resulting suspension for 12 hours, age at 90°C for 3 hours, wash with hot water, suction filter, 110°C Drying for 6 hours and calcining at 400 °C for 4 hours prepared mesoporous Ce 0.8 Zr 0.2 o 2 The powder, its XRD, nitrogen adsorption and desorption analysis, and TEM analysis are shown in Figures 1, 3, and 4.

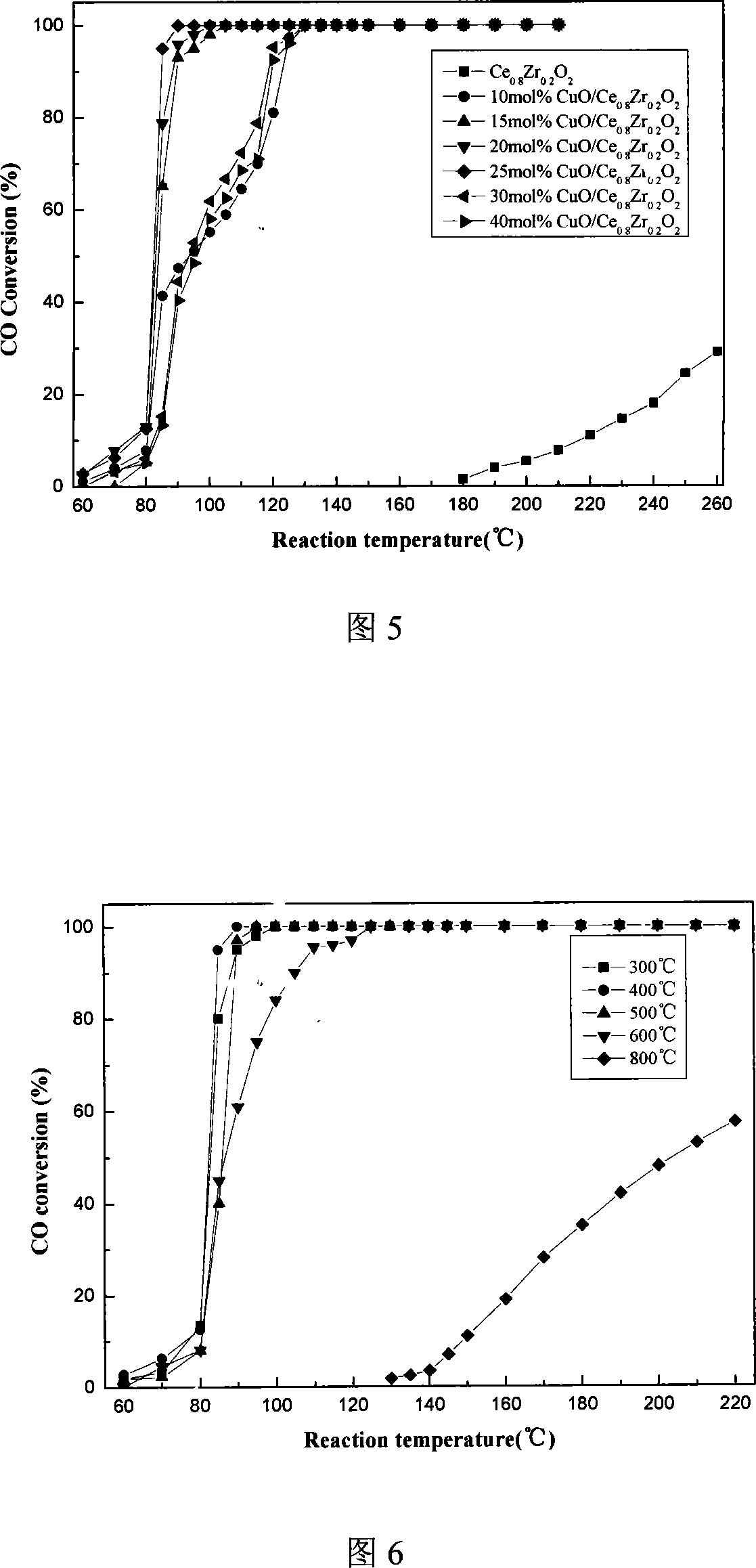

[0027] The activity evaluation of the catalyst is carried out in a fixed-bed continuous flow differential reactor. The reactor is a stainless steel tube with an inner diameter of 7mm, the catalyst loading is 200mg, the feed gas composition is air containing 10% CO (volume ratio), and the space velocity is 11000mlh -1 g -1 , CO and CO in the product gas after 15 minutes of rea...

Embodiment 2

[0029] At room temperature, weigh 6 mmol of CTAB, dissolve it in 200 mL of deionized water, and ultrasonically disperse for 15 minutes. Under vigorous stirring, a calculated amount of Cu(NO 3 ) 2 ·3H 2 O, Ce(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O (Ce, Zr molar ratio 4:1), continue to stir for 30 minutes, add 0.2M NaOH solution until the pH value is 10, stir the resulting suspension for 12 hours, age at 90°C for 3 hours, wash with hot water, and suction filter , dried at 110°C for 6 hours and calcined at 400°C for 4 hours to prepare mesoporous CuO / Ce 0.8 Zr 0.2 o 2 catalyst.

[0030] The activity evaluation of the catalyst is carried out in a fixed-bed continuous flow differential reactor. The reactor is a stainless steel tube with an inner diameter of 7mm, the catalyst loading is 200mg, the feed gas composition is air containing 10% CO (volume ratio), and the space velocity is 11000mlh -1 g -1 , CO and CO in the product gas after 15 minutes of reaction 2 The co...

Embodiment 3

[0032] Change the CuO mole percentage in Example 2 from 25% to 10%, and the others are the same as in Example 2. The catalytic activity results are shown in Figure 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com