Polyester resin, molded object thereof, and processes for producing the same

一种制造方法、聚酯树脂的技术,应用在其他家里用具、应用、家里用具等方向,能够解决不能获得高聚合度的聚合物、不能获得高品质的聚合物、没有给出低分子量挥发性物质含量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

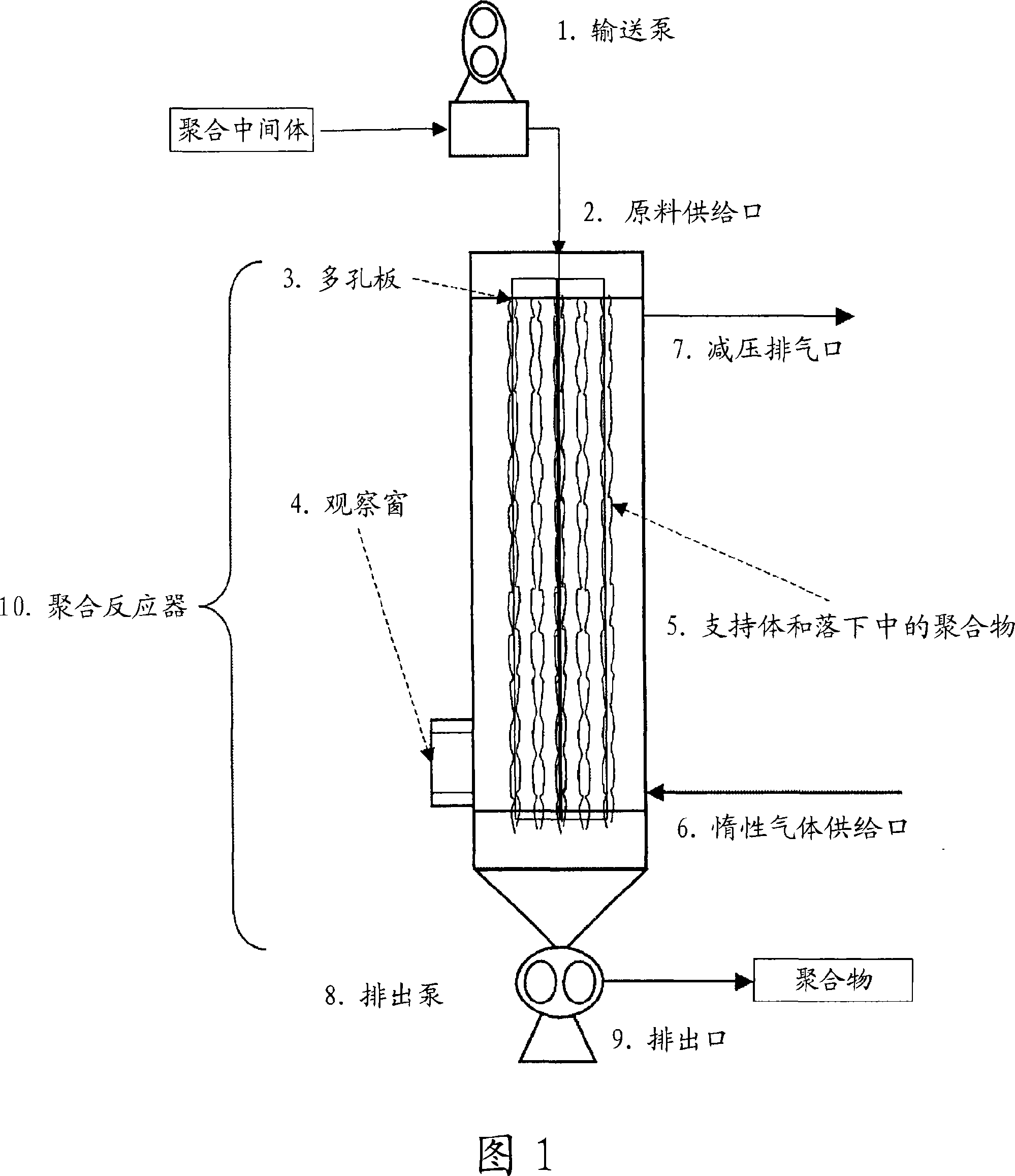

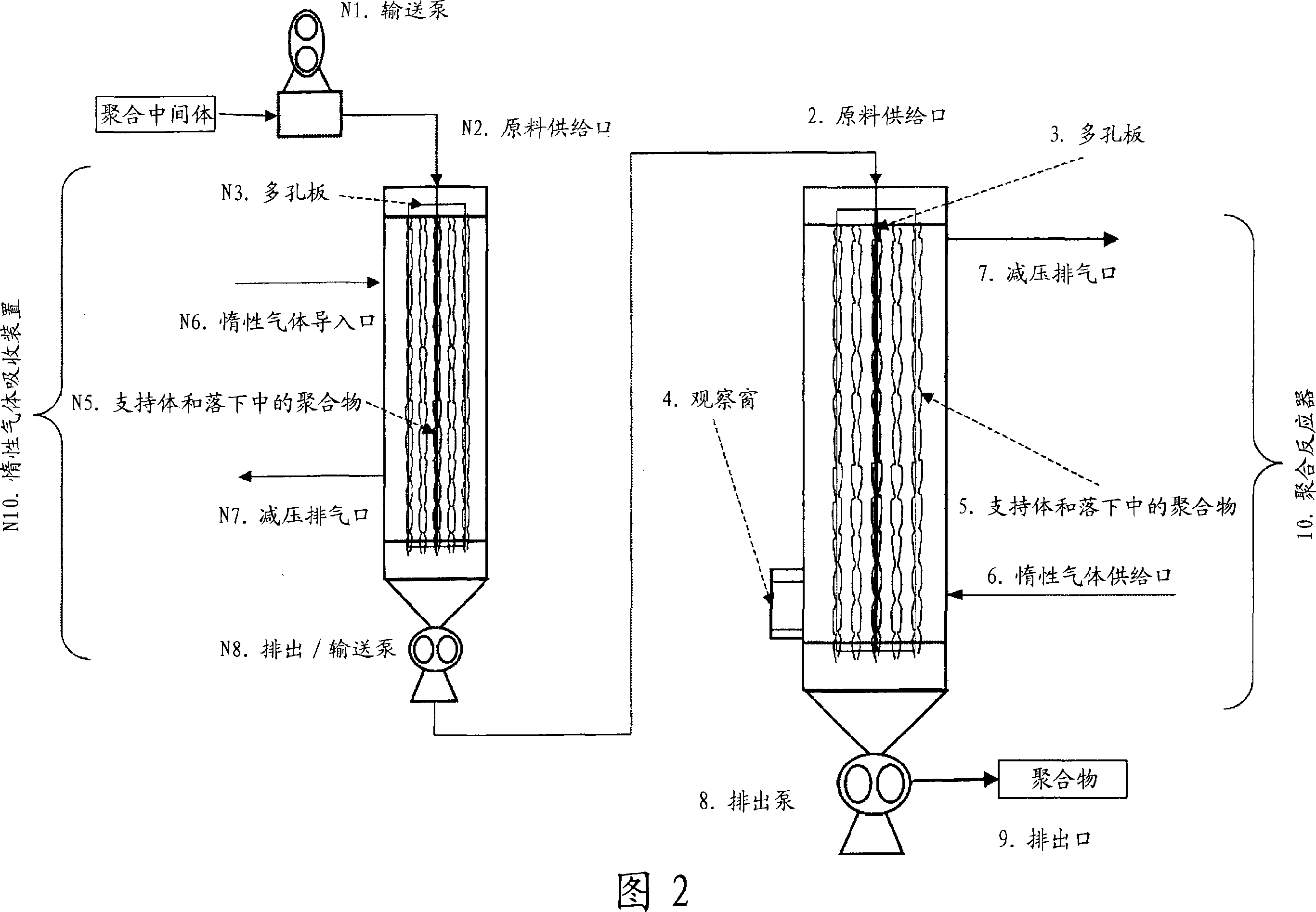

[0420] Hereinafter, examples of a preferred polymerization reactor and a preferred polymerization method used in the present invention will be described with reference to the accompanying drawings.

[0421] Fig. 1 shows a specific example of a polymerization reactor suitable for producing the polyester resin of the present invention. Polymerization intermediates of polyester resin are supplied from raw material supply port 2 to polymerization reactor 10 by delivery pump 1 , introduced into the polymerization reactor through perforated plate 3 and dropped along support 5 . The inside of the polymerization reactor is adjusted to a predetermined degree of reduced pressure. EG generated from the polymerization intermediate as a by-product, and an inert gas such as nitrogen introduced from the inert gas supply port 6 if necessary, are exhausted from the decompression exhaust port 7 . The highly polymerized polyester resin was discharged from a discharge port 9 using a discharge pu...

Embodiment 1

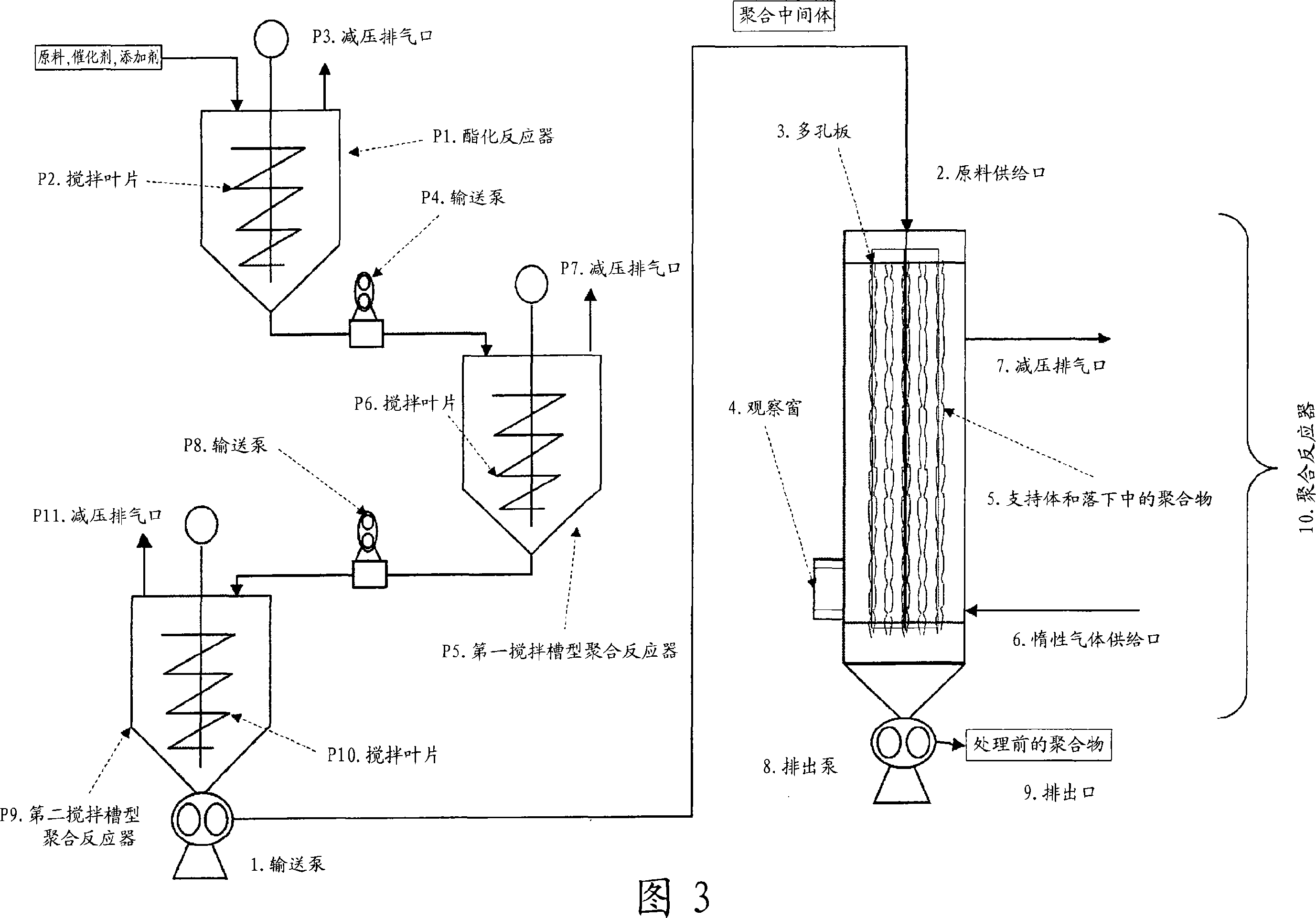

[0506] Using the apparatus shown in FIG. 3 and high-purity terephthalic acid and EG as raw materials, PET resin was polymerized by a continuous polymerization method at an average rate of 2.4 kg per hour. Use the vertical stirring polymerization reactor that has paddle shape stirring blade (P2, P6, P10) as esterification reactor (P1) and the first stirring tank type polymerization reactor (P5) and the second stirring tank type polymerization reactor (P9 ), polymerized under reduced pressure in the final polymerization reactor (10) by allowing the material to drain from the holes on the perforated plate (3) and let it fall along the support (5). Under the conditions shown in Table 1 and Table 3, polymerization was performed by continuously feeding a slurry-like mixture of 1:1.2 (molar ratio) terephthalic acid and EG to the esterification reactor. The structure of Support 1 used here is as described in Table 9.

[0507] In this operation, 0.04% by weight of antimony trioxide an...

Embodiment 2

[0516] By following the same method as in Example 1, the PET resin was polymerized by a continuous polymerization method at an average rate of 5.5 kg per hour under the conditions shown in Table 1 and Table 4.

[0517]The perforated plate (3) is 50 mm thick, and the diameter of the holes is 1 mm. They are linearly arranged in two parallel rows with an interval of 10 mm, each row has 7 holes, and the row spacing is 70 mm.

[0518] The support (5) (support 2 in Table 9) is made of 2mm diameter and 8m long wires, each wire is hung vertically and placed near each hole, and the 2mm diameter and 100mm long wires are separated by 100mm intervals. Cross the upper group of seven wires at right angles to form a metal mesh. Two pieces of this metal mesh were used (Table 9).

[0519] The properties of the polymerization intermediates are shown in Table 1 and Table 4. 10 kg of polymerized pellets were put into a vat and heat-treated in a hot air dryer at 130° C. for 10 hours, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com