Coking benzene deep desulfuration purification method

A technology for deep desulfurization and coking of benzene, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of short regeneration cycle of adsorbent, inability to completely remove thiophene, complicated process, etc., and reach the level of environmental pollution low, mild reaction and adsorption conditions, and simple method flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

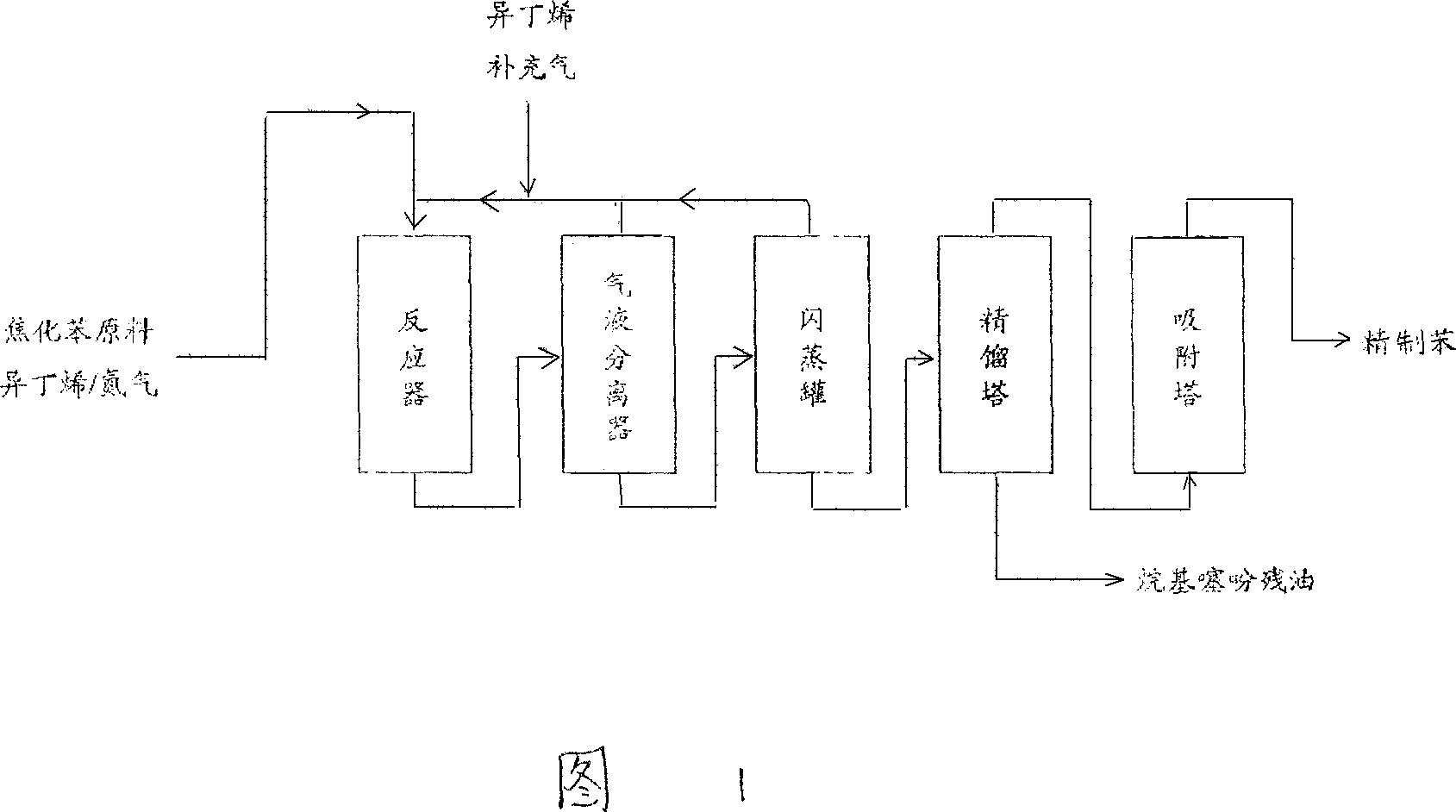

Method used

Image

Examples

Embodiment 1

[0022] Take industrial water glass (modulus 3.3, Na 2 O%=8.3, SiO 2 %=26~28) is the silicon source, sodium aluminate is the aluminum source, cetyltrimethylammonium bromide (CTAB) is the template, and the molar ratio is SiO 2 :Al 2 o 3 :CTAB:H 2 O=60:1:5:1200, using the traditional hydrothermal method to synthesize MCM-41, after roasting, 0.4mol / LNH 4 NO 3 The HMCM-41 zeolite molecular sieve was prepared by ion exchange three times in the solution, impregnated and modified with 0.8 mol / L sulfuric acid aqueous solution, and dried and roasted to obtain a solid acid catalyst. With the coking benzene that contains 500mg / L thiophene (about 0.05%wt) as raw material, isopentene is alkylating agent, at reaction temperature 200 ℃, 2.0MPa, the coking benzene solution that contains 5%wt isopentene is with mass air The speed is 2.33h -1 The flow rate is passed into the fixed bed reactor for thiophene alkylation reaction, and the thiophene in benzene is almost completely converted in...

Embodiment 2

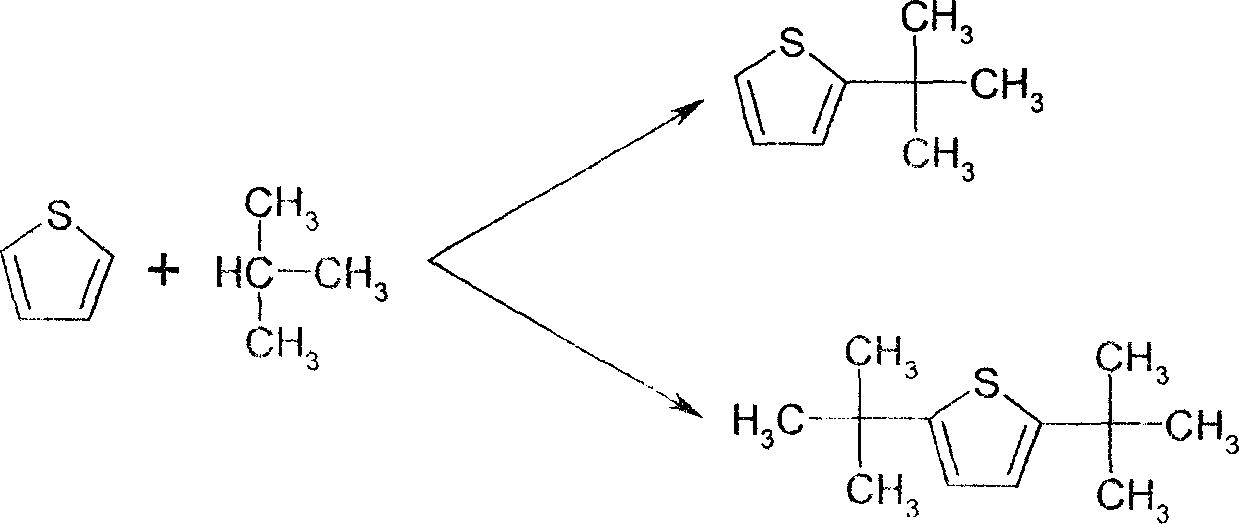

[0024] The raw material coking benzene comes from industrial raw materials after pickling, in which the thiophene content is 235mg / L, the bromine index is 65mgBr / 100g, the acidic zeolite molecular sieve HMCM-41 (Si / Al=60) is used as the catalyst, and isobutylene is used as the alkylating agent , at a reaction temperature of 85°C, normal pressure, and a raw material coking benzene feed weight space velocity of 2.4h -1 , the flow rate of isobutylene gas (gas distribution with nitrogen in a 1:1 molar ratio) is 2mL / min, and the comprehensive sample of reaction 150h is removed by rectification of a rectification tower with a theoretical plate of 15 to remove heavy component alkylthiophene, and the content of thiophene in the gained benzene product Below 4mg / L, the alkylation rate of thiophene is as high as 98.3%, and the activity of the catalyst has no obvious downward trend. The benzene product after alkylation desulfurization is at room temperature, normal pressure, and the mass ...

Embodiment 3

[0026] Using coked light benzene containing 3350mg / L thiophene (from the benzene-toluene-xylene mixed fraction after the crude benzene is processed by the pre-fractionation unit, which contains 80.7% of benzene, 15.4% of toluene, and 3.5% of xylene) as raw material, N -Methylpyrrolidone is the extraction agent, the actual number of plates in the rectification tower is 45, the solvent ratio is 3 (that is, the ratio of the volume flow rate of the extraction agent to the raw material coking light benzene), and the reflux ratio is 3. When the temperature is 78--80°C and the temperature of the tower bottom is 159--165°C, the concentration of thiophene in the coked benzene in the overhead fraction of the extractive distillation tower will drop to about 189mg / L. The coked benzene product is mixed with concentrated sulfuric acid at a ratio of 10:1 (volume ratio of coked benzene and concentrated sulfuric acid), pickled for 15 minutes at a temperature of 50°C under vigorous stirring, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com