Liquid state preparation method for nano cadmium sulfide hollow sphere

A technology of cadmium sulfide and hollow spheres, which is applied in the direction of cadmium sulfide, etc., can solve the problems of many influencing factors of the reaction system, limit the wide application, and long production cycle, and achieve the effect of easy-to-obtain raw materials, good process repeatability, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

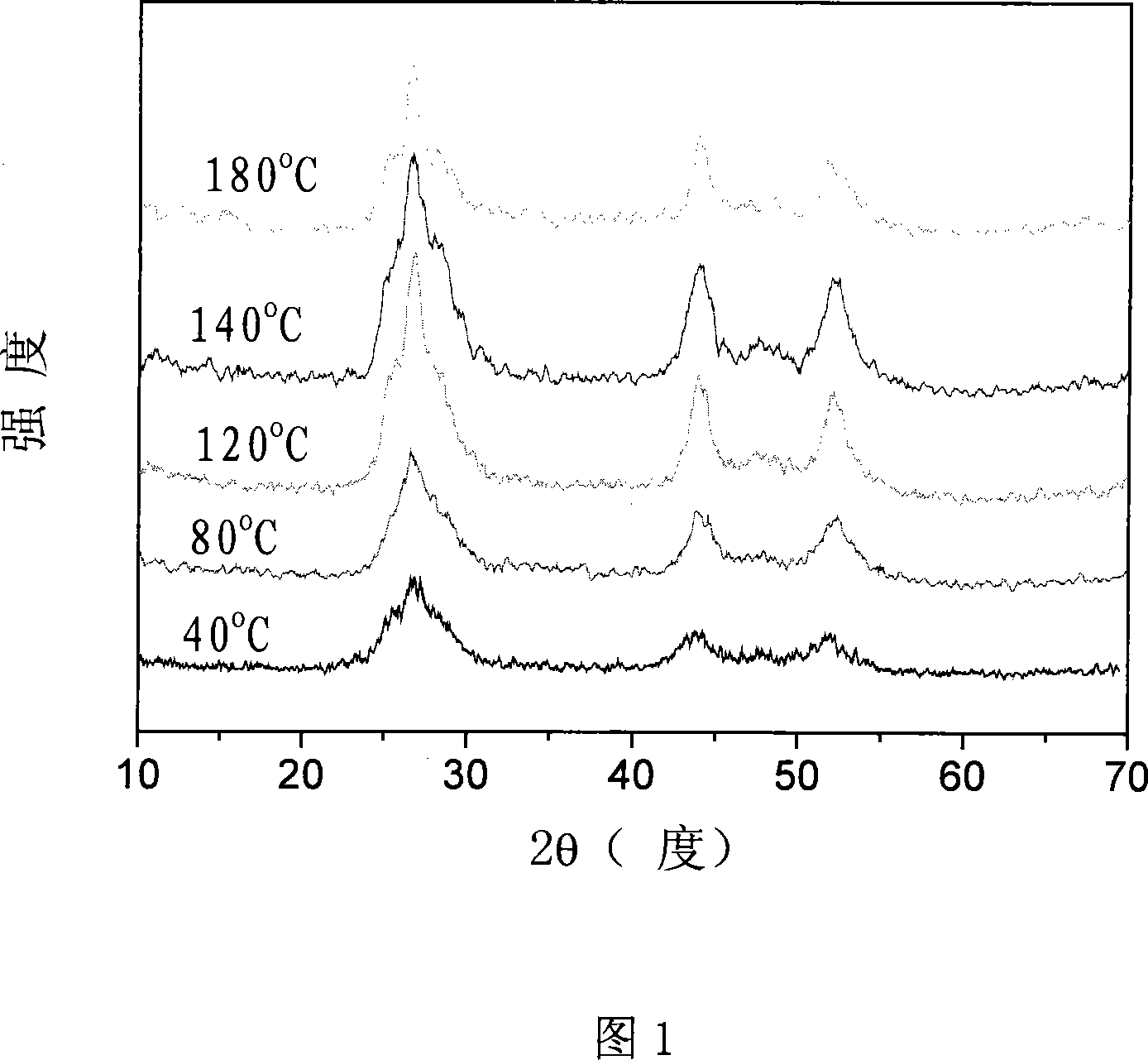

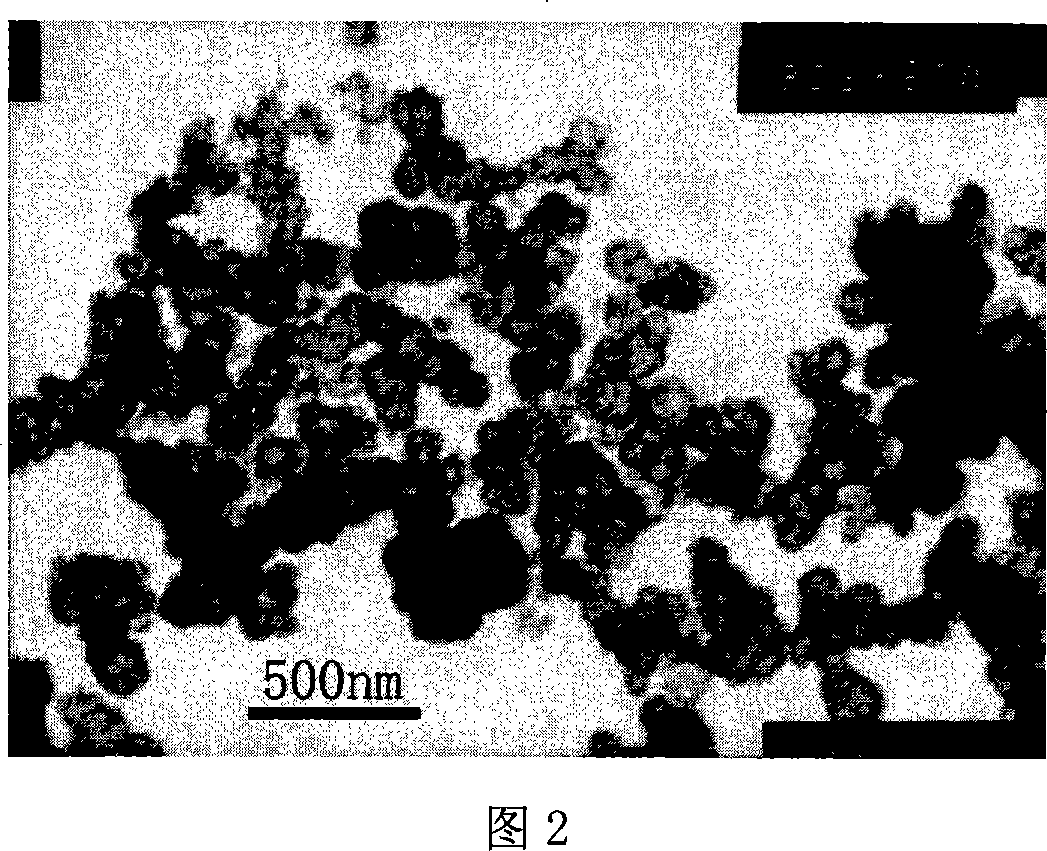

[0026] Weigh 5mmol of CdCl 2 2.5H 2 O solid was placed in a 60ml wide-mouth bottle, 30ml of distilled water was added and stirred to obtain a clear and transparent colorless solution, which was then heated in a water bath at 80°C. In addition, 6.5 mmol of sublimed sulfur was weighed and dissolved in 5-10 ml of ethylenediamine, and after all the dissolution, a dark red solution was obtained. Add sulfur powder dissolved in ethylenediamine solution to CdCl 2 In the aqueous solution, after continuing to stir for 8 hours, the mixed solution was separated by suction filtration, washed with water and ethanol, and dried in vacuo to obtain a yellow powder. The product was identified as cadmium sulfide by X-ray powder diffraction (accompanying drawing 1), and was identified as nanoscale cadmium sulfide hollow spheres by transmission electron microscopy (accompanying drawing 2). The diameter of the hollow sphere is 80-150 nanometers, and the diameter of the spherical shell is about 10...

Embodiment 2

[0029] Weigh 5mmol of CdCl 2 2.5H 2 O solid is placed in the reactor of 60ml, adds 30ml distilled water, stirs, and obtains clear and transparent colorless solution. In addition, 6.5 mmol of sublimed sulfur was weighed and dissolved in 10 ml of ethylenediamine, and a dark red solution was obtained after all the dissolution. Add sulfur powder dissolved in ethylenediamine solution to CdCl 2 In the aqueous solution, continue stirring for 30 minutes, seal the reaction vessel, react at 120°C for 10 hours, then cool to room temperature, open the reaction vessel, separate the reaction solution by suction filtration, wash with water and ethanol, and obtain a yellow powder after vacuum drying. Product is identified as cadmium sulfide (accompanying drawing 3) through X-ray powder diffraction, is identified as nanoscale cadmium sulfide hollow spheres by scanning electron microscope (accompanying drawing 3) and transmission electron microscope (accompanying drawing 4), and the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com