Process for purifying zinc from casting zinc residue

A zinc slag and process technology, which is applied in the field of non-ferrous metal recovery, can solve the problems of many types of impurity metal ions, large acid consumption in the leaching section, and high energy consumption in electrowinning, and achieve low labor intensity, reduced investment costs, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

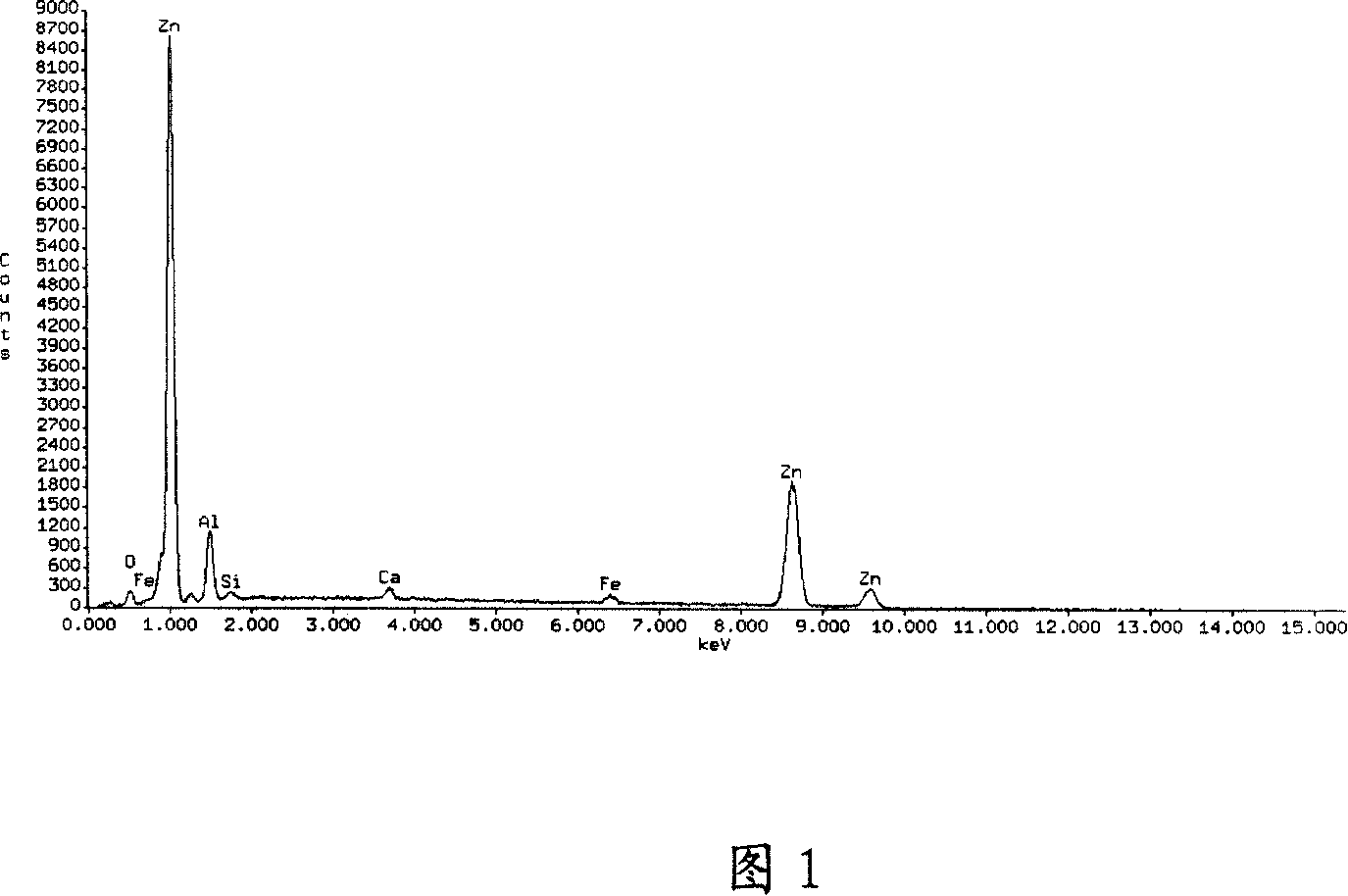

[0026] The energy spectrum (EDS) analysis of the composition of the molten zinc slag is shown in Figure 1. It can be seen that the impurities in zinc slag are mainly aluminum, iron, oxygen, silicon, and calcium. The specific content is shown in Table 1. The content of impurities is not high, especially the content of iron, which has the most significant impact on melting and casting. Heat the zinc slag to 600°C in a reducing atmosphere, and cast it directly into an anode plate. The size of the mold is 6cm×5cm×1cm (length×width×thickness).

[0027] Impurity name

Content (wt%)

aluminum

iron

4.34

1.39

2.08

0.69

0.38

[0028] The zinc plate melted and cast with the above-mentioned fused and cast zinc slag prepared above is used as the anode plate, the cathode plate is made of pure aluminum plate, and the specification is 5cm×5cm×1cm (length×width×thickness), and the con...

Embodiment 2

[0031] The electrolysis parameters are electrolysis temperature 30°C, homopolar spacing 12cm, current density 600A / m 2 , electrolysis for 24 hours, no need to stir during electrolysis. Others are the same as embodiment 1.

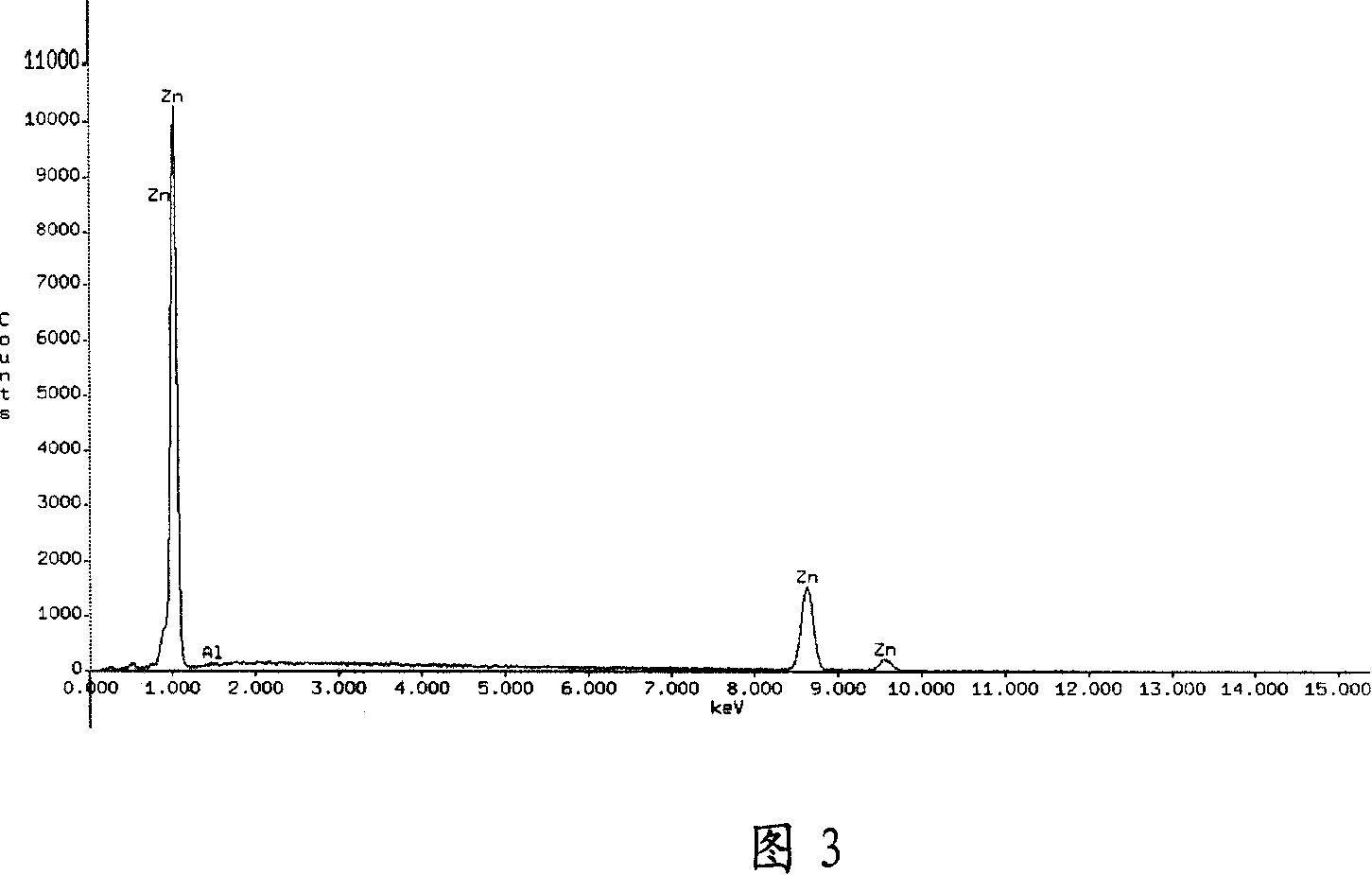

[0032] The current efficiency of the electrolysis process is 98.6%, and the obtained cathode zinc is compact and bright, but the phenomenon of dendritic growth on the cathode plate is relatively serious. The results of energy spectrum analysis are shown in Figure 3, and the composition is shown in Table 3. It can be seen that compared with the analysis results of cathode zinc obtained in Example 1, there is not much change.

[0033] Figure 4 is the XRD analysis result of the cathode zinc product. It can be seen that the characteristic peaks of each angle in the figure are almost all characteristic peaks of zinc element. On the one hand, it shows that the cathode zinc product has a high purity; on the other hand, it shows that zinc is on the cathode plate ...

Embodiment 3

[0036] The electrolysis parameters are electrolysis temperature 30°C, homopolar spacing 12cm, current density 400A / m 2 , electrolysis for 24 hours, no need to stir in the electrolysis process, other conditions are the same as in Example 1.

[0037] The current efficiency of the electrolysis process is 99.3%, the obtained cathode zinc is dense and bright, and there are slight nodules growing on the cathode plate. The results of energy spectrum analysis are shown in Figure 5, and the composition is shown in Table 4. It can be seen that compared with the analysis results of cathode zinc obtained in Example 1, there is not much change.

[0038] element name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com