Pyrolytic treatment method for chromium slag

A treatment method and technology for chrome slag, which are applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of difficult chrome slag treatment and high cost of microwave technology, reduce equipment investment and operating costs, and improve energy use. efficiency, reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

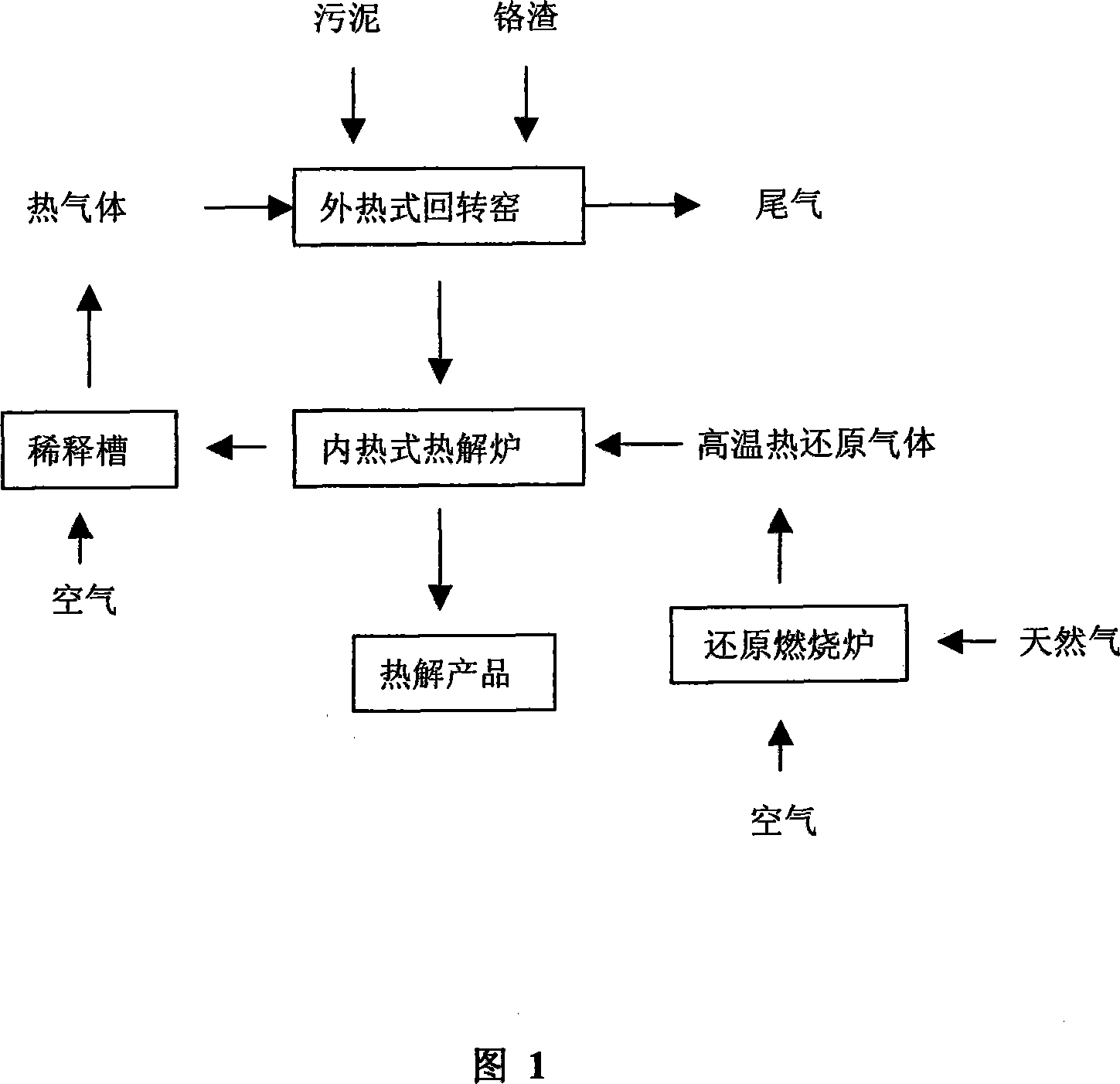

Image

Examples

Embodiment 1

[0024] After the chromium residue is ground to 60 mesh, it is mixed with dewatered sludge (water content 80%), the mass ratio of chromium residue to sludge is 1:0.5, and the mixture is sent into the inner cylinder of the externally heated rotary furnace through a screw feeder for further processing. Preheating and drying, the mixture stays in the inner drum of the externally heated rotary kiln for 0.25 hours, so that the moisture content of the dried mixture is lower than 5%.

[0025] The reduction combustion furnace uses natural gas as fuel, and the air excess coefficient in the reduction combustion furnace is controlled to be 0.9. The temperature of the generated hot gas is about 500°C, and the oxygen content is less than 0.5%. The generated high-temperature hot gas is introduced into the internal heating type pyrolysis furnace.

[0026] Send the mixture preheated by the external heating rotary furnace into the internal heating pyrolysis furnace, and directly contact the high...

Embodiment 2

[0031] After grinding the chromium slag to 60 mesh, mix it with dewatered sludge (moisture content 60%), the mass ratio of chromium slag and sludge is 1:2, and send the mixture into the inner cylinder of the externally heated rotary furnace through a screw feeder. Preheating and drying, the mixture stays in the inner drum of the externally heated rotary kiln for 0.25 hours, so that the moisture content of the dried mixture is lower than 5%.

[0032] The reduction combustion furnace uses natural gas as fuel, and the air excess coefficient in the reduction combustion furnace is controlled to be 0.8. The temperature of the generated hot gas is 650°C, and the oxygen content is less than 0.5%. The generated high-temperature hot gas is introduced into the internal heating type pyrolysis furnace.

[0033] Send the mixture preheated by the external heating rotary furnace into the internal heating pyrolysis furnace, and directly contact the high temperature hot gas with a temperature of...

Embodiment 3

[0038] After grinding the chromium slag to 60 mesh, mix it with dewatered sludge (moisture content 60%), the mass ratio of chromium slag to sludge is 1:0.5, and send the mixture into the inner cylinder of an externally heated rotary furnace through a screw feeder for further processing. Preheating and drying, the mixture stays in the inner barrel of an externally heated rotary kiln for 4 hours, so that the moisture content of the dried mixture is lower than 5%.

[0039] The reduction combustion furnace uses natural gas as fuel, and the air excess coefficient in the reduction combustion furnace is controlled to be 0.8. The temperature of the generated hot gas is 500°C, and the oxygen content is less than 0.5%. The generated high-temperature hot gas is introduced into the internal heating type pyrolysis furnace.

[0040] Send the mixture preheated by the external heating rotary furnace into the internal heating pyrolysis furnace, and directly contact the high temperature hot gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com