System for preparing micro particles with hydraulic cavitation reinforcing supercritical auxiliary atomizing and its method

A hydraulic cavitation and supercritical technology, which is applied in the direction of liquid separation into beads and granulation, can solve problems such as long residence time, early precipitation of solutes, and impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

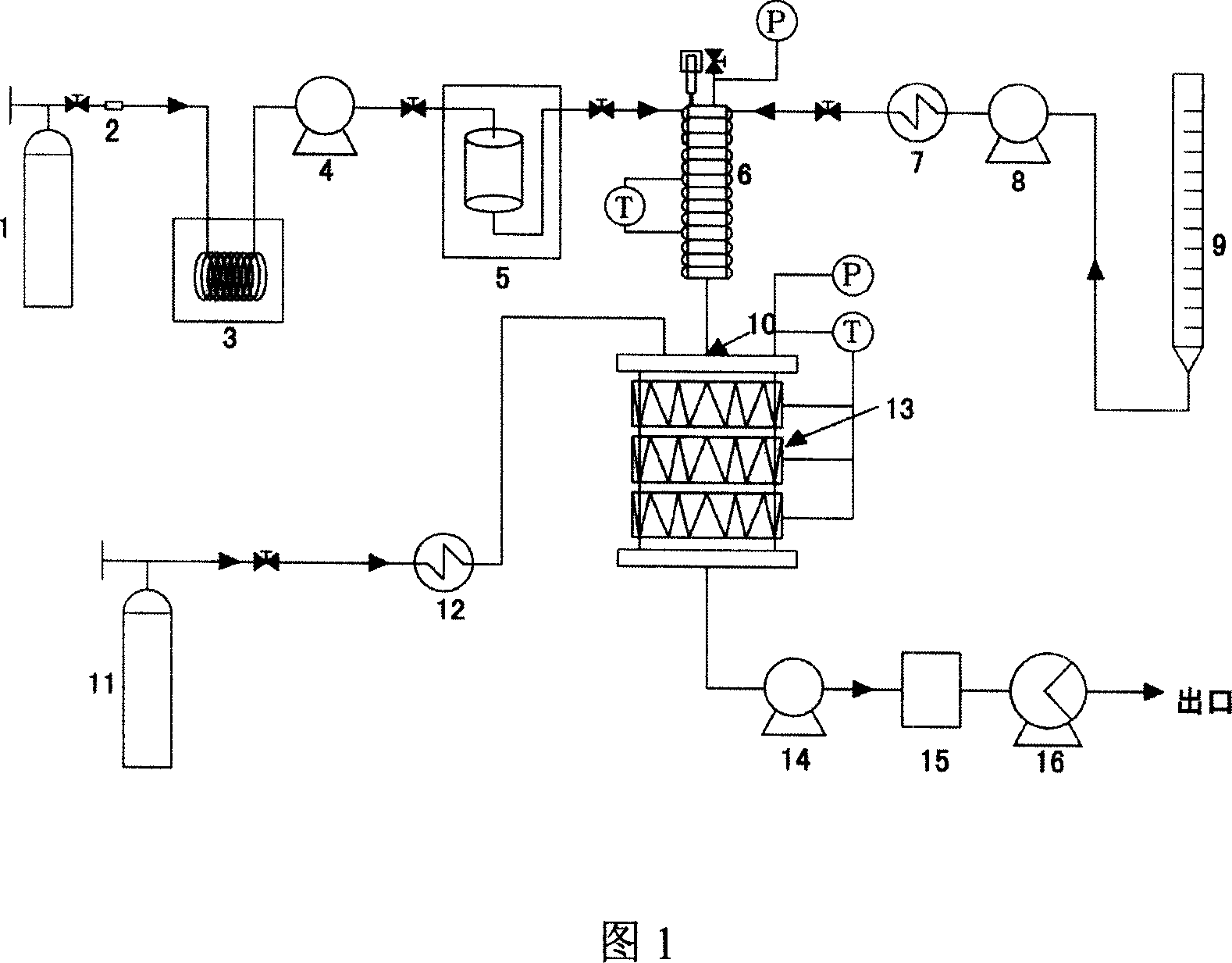

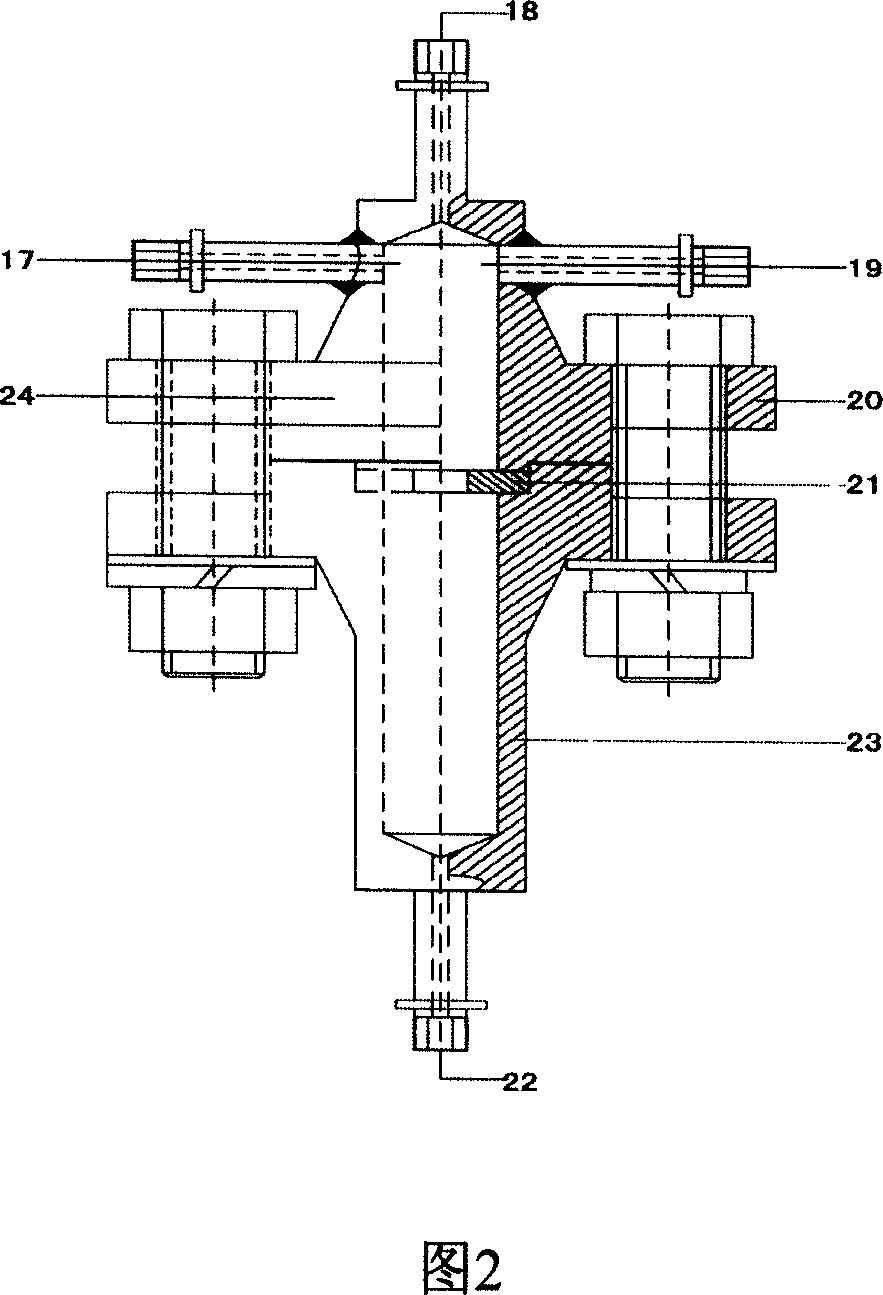

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of levofloxacin hydrochloride microparticles

[0024] First prepare an appropriate amount of levofloxacin hydrochloride methanol solution with a concentration of 2mg / ml, and preheat the solution to 40°C with a water bath; adjust the inner diameter of the nozzle to 200μm; turn on the compressor, and heat the CO in the buffer tank 2 Increase the pressure to 8MPa, heat the temperature control box to 40°C; set the temperature control of the precipitator to 60°C, and feed 40NL / min of nitrogen preheated to 60°C. Then feed 60g / min CO into the hydraulic cavitation mixer 2 Fluid, the copper sieve plate porosity (single hole) is 1 / 8; The hydraulic cavitation mixer is boosted to 8MPa, then pumps into the levofloxacin hydrochloride methanol solution of 25ml / min in the hydraulic cavitation mixer, and the residence time is 40 ~60 seconds, the pressure of the hydraulic cavitation mixer is accurately controlled at 8MPa (±0.1MPa); after the mist droplets a...

Embodiment 2

[0025] Embodiment 2: Preparation of polylactic acid microparticles

[0026]First prepare an appropriate amount of polylactic acid dichloromethane solution with a concentration of 6mg / ml, and preheat the solution to 40°C with a water bath; adjust the inner diameter of the nozzle to 100μm; turn on the compressor, and heat the CO in the buffer tank. 2 Increase the pressure to 8MPa, heat the temperature control box to 40°C; set the temperature control of the precipitator to 70°C, and feed 40NL / min of nitrogen preheated to 70°C. Then feed 50g / min CO into the hydraulic cavitation mixer 2 Fluid, the porosity of the copper sieve plate (8 round holes of 1mm) is 0.32; the hydraulic cavitation mixer is boosted to 8MPa, and then 35ml / min of polylactic acid dichloromethane solution is pumped into the hydraulic cavitation mixer, The residence time is 40-60 seconds, and the pressure of the hydraulic cavitation mixer is precisely controlled at 8MPa (±0.1MPa); after the mist droplets appear a...

Embodiment 3

[0027] Embodiment 3: the preparation of aspirin microparticles

[0028] First prepare an appropriate amount of aspirin ethanol solution with a concentration of 2mg / ml, and preheat the solution to 60°C with a water bath; adjust the inner diameter of the nozzle to 200μm; turn on the compressor, and heat the CO in the buffer tank. 2 Increase the pressure to 9MPa, heat the temperature control box to 60°C; set the temperature control of the precipitator to 90°C, and inject 50N L / min of hot nitrogen preheated to 90°C. Then feed 65g / min CO into the hydraulic cavitation mixer 2 Fluid, copper sieve plate porosity (single hole) is 1 / 10; boost the hydraulic cavitation mixer to 9MPa, then pump 40ml / min aspirin ethanol solution into the hydraulic cavitation mixer, the residence time For 40 to 60 seconds, the pressure of the hydraulic cavitation mixer is precisely controlled at 9MPa (±0.1MPa); after mist droplets appear at the outlet of the nozzle, the vacuum pump is turned on, and the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com