Method for manufacturing charcoal / charcoal pantograph pan in use for electric locomotive

A technology for pantograph slides and electric locomotives, applied in cable/conductor manufacturing, electric vehicles, conductive materials dispersed in non-conductive inorganic materials, etc. In order to solve problems such as low strength, it can achieve the effects of good lubricating performance, small amount of wear, excellent mechanical properties and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

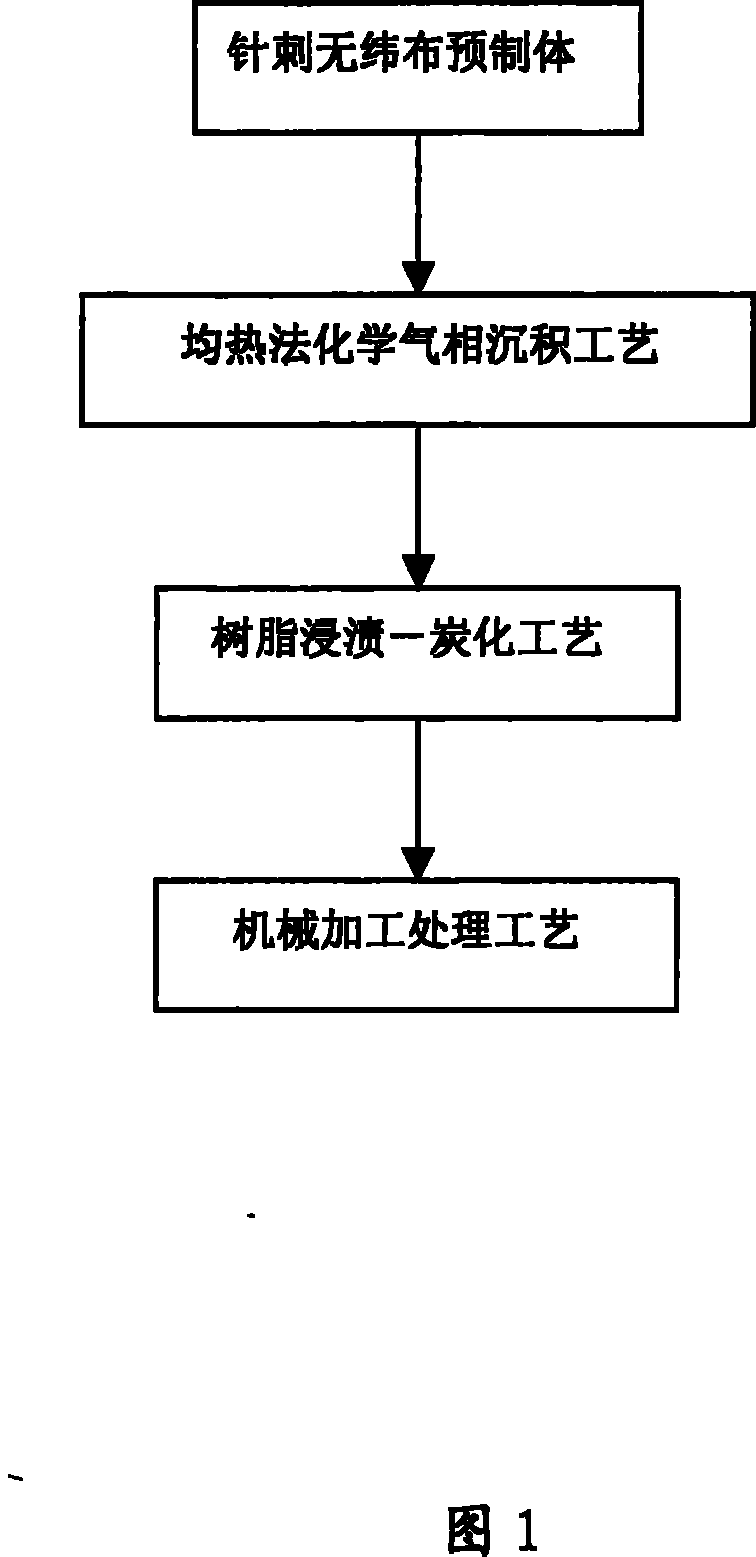

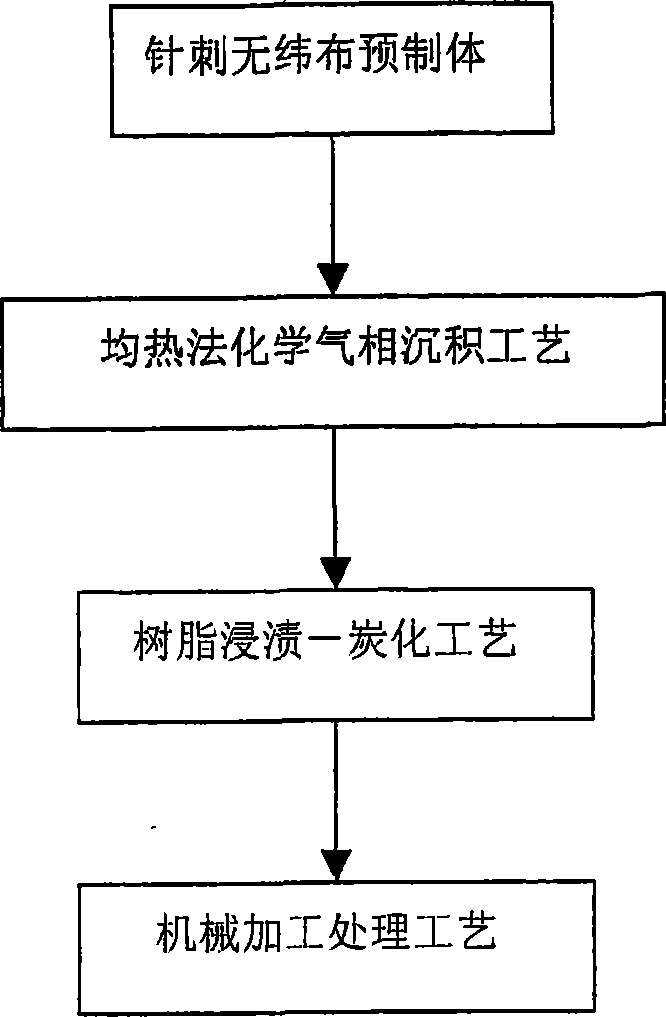

Method used

Image

Examples

Embodiment 1

[0020] (1) The quasi-three-way structure prefabricated body is adopted with full carbon fiber acupuncture without weft cloth;

[0021] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional prefabricated body, the deposition temperature is 920 ° C, the deposition time is 168 hours, and the deposition density is ≥ 1.20 g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0022] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.8MPa for 5h, the curing temperature is 160°C and then transferred to a carbonization furnace for carbonization treatment at 800°C;

[0023] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

Embodiment 2

[0025] (1) Acupuncture non-weft full carbon fiber quasi-three-way structure prefabricated body;

[0026] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional structure preform, the deposition temperature is 940°C, the deposition time is 120 hours, and the deposition is to a density ≥ 1.20g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0027] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.4MPa for 5 hours, the curing temperature is 180°C, and then transferred to a carbonization furnace for carbonization at 900°C;

[0028] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

Embodiment 3

[0030] (1) Acupuncture non-weft full carbon fiber quasi-three-way structure prefabricated body;

[0031] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional structure preform, the deposition temperature is 960°C, the deposition time is 144 hours, and the deposition is to a density ≥ 1.20g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0032] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.2MPa for 5 hours, the curing temperature is 200°C and then transferred to a carbonization furnace for carbonization treatment at 1000°C;

[0033] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

[0034] The invention introduces the carbon / carbon composite material to be used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com