Film photoetching manufacturing method of plasma display plate electrode and its product

A plasma and manufacturing method technology, which is applied in the manufacture of electrode systems, the manufacture of discharge tubes/lamps, and the manufacture of cold cathodes, etc., can solve the problems of electrode line defects, bubble amplification, defect point multiplication, etc., and achieves low manufacturing difficulty and cost. , Improve the quality and reduce the effect of defect points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

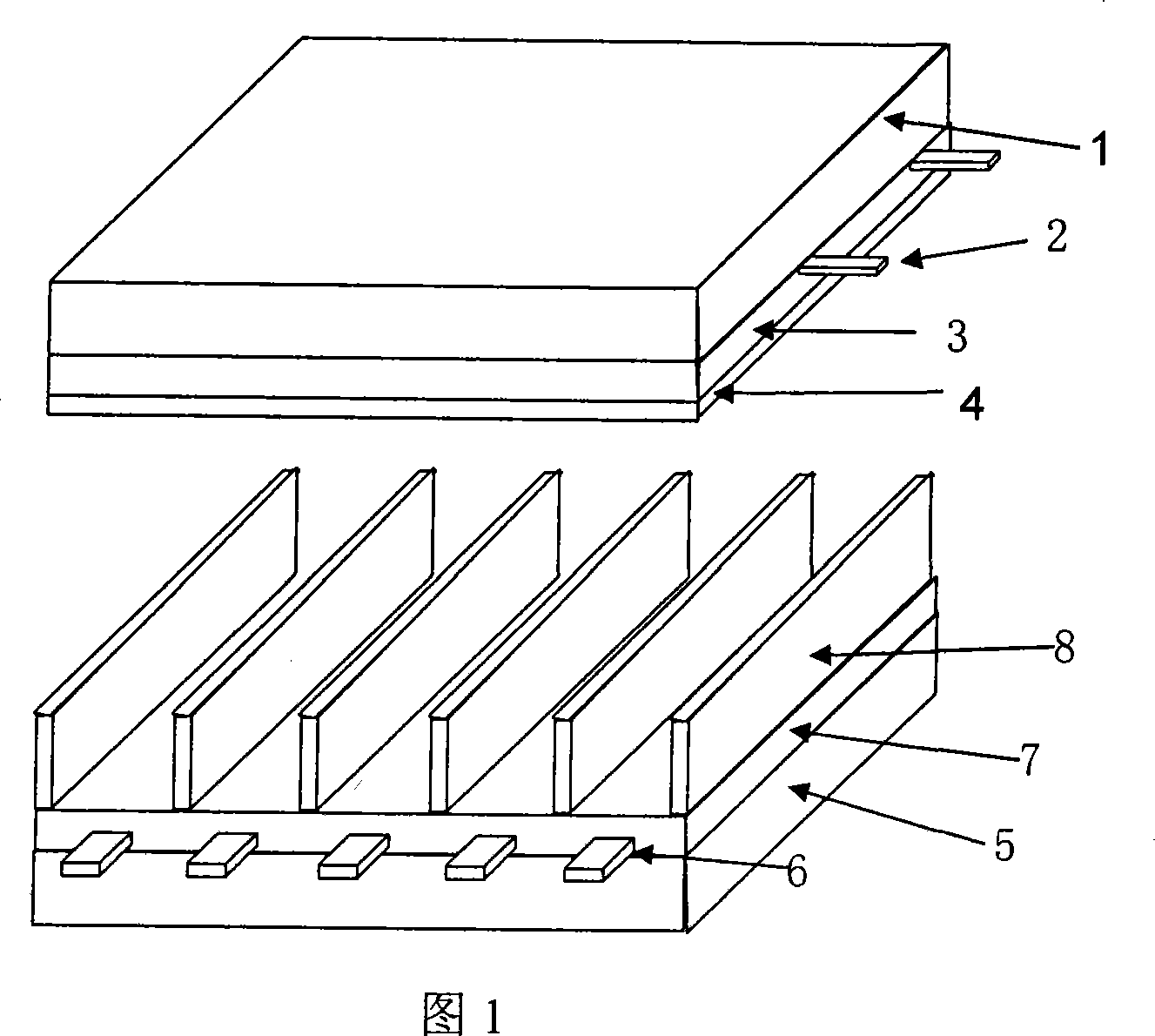

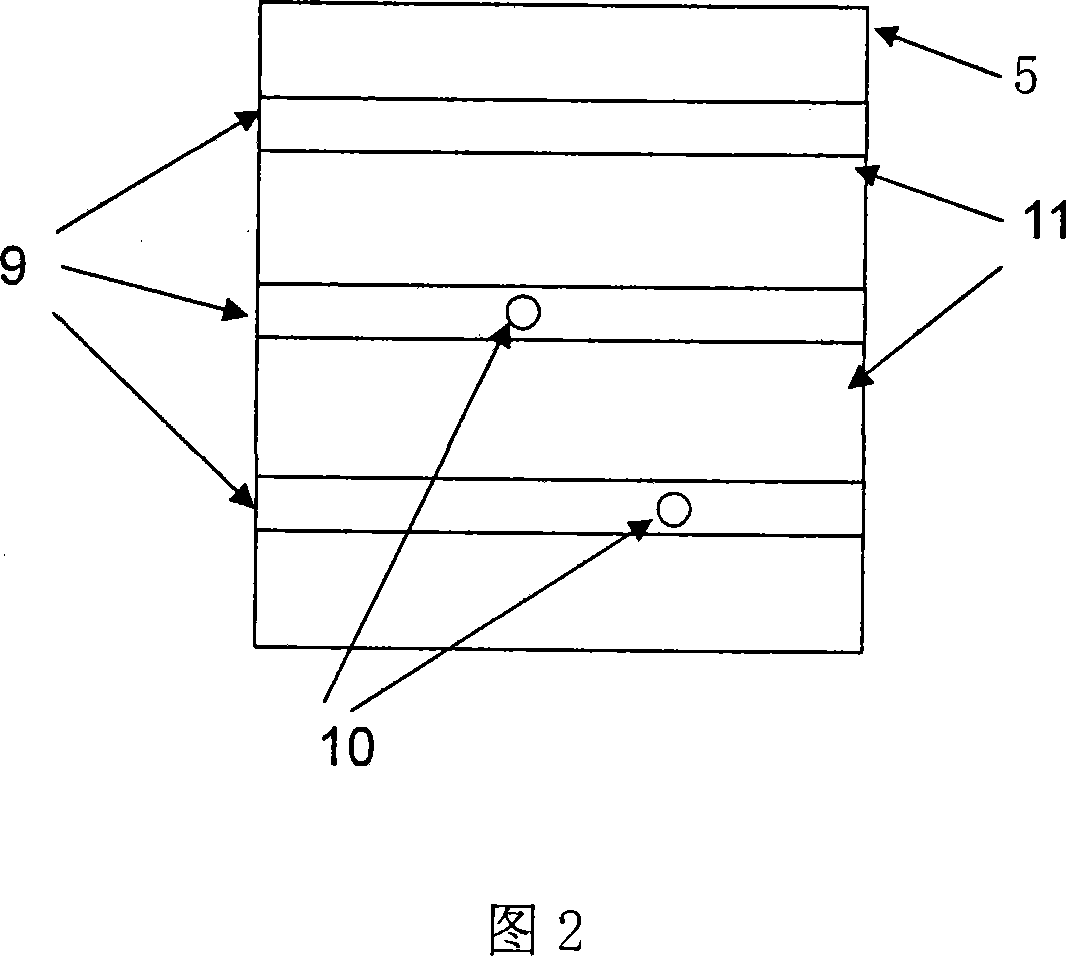

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] A thin-film photolithographic manufacturing method for electrodes of a plasma display panel, comprising a front substrate electrode group and a rear substrate electrode group, which are all sequentially manufactured by the following steps:

[0036] (1) Evaporation of thin film electrodes; the process conditions and work steps of this step are the same as those of the prior art;

[0037] (2) coating of photosensitive material (adopting dry film hot pressing to carry out); The technological condition of this step and work step are identical with prior art, and dry film hot pressing wherein is meant that photosensitive material is made into the dry film of uniform thickness, Then place the dry film between the substrate and the hot pressing roller, and make the substrate pass through the hot pressing roller to press the dry film on the substrate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com