Circularly geoheat exchanging underground energy-accumulating liquid reservoir and its construction process

A heat-exchanging, energy-storing fluid technology, applied in geothermal energy power generation, heating methods, construction, etc., can solve the problems of deep underground drilling of vertical buried pipes, expensive urban land, and poor heat exchange effect, etc., to achieve construction Improve work efficiency, avoid thermal pollution and adverse effects, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

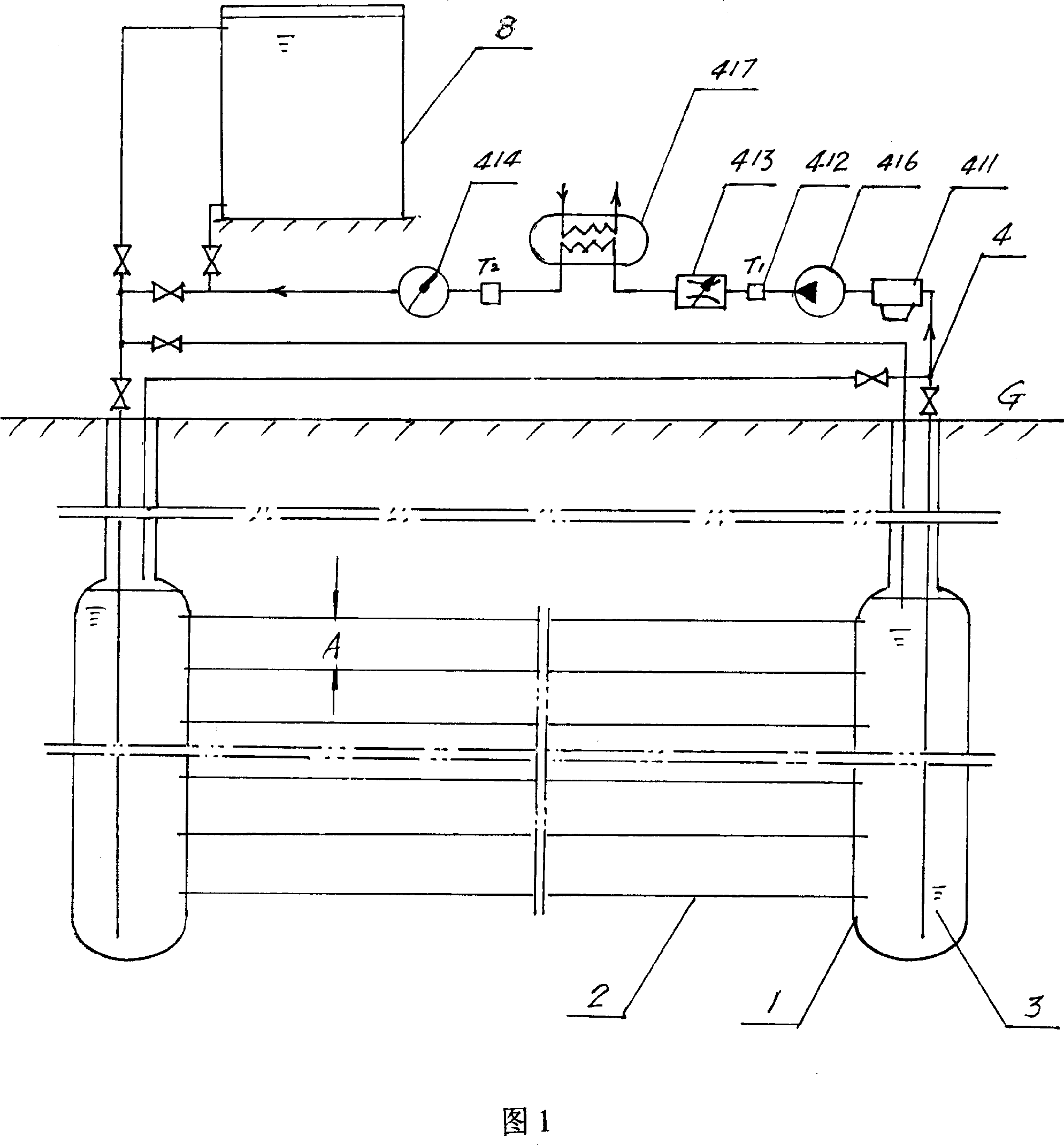

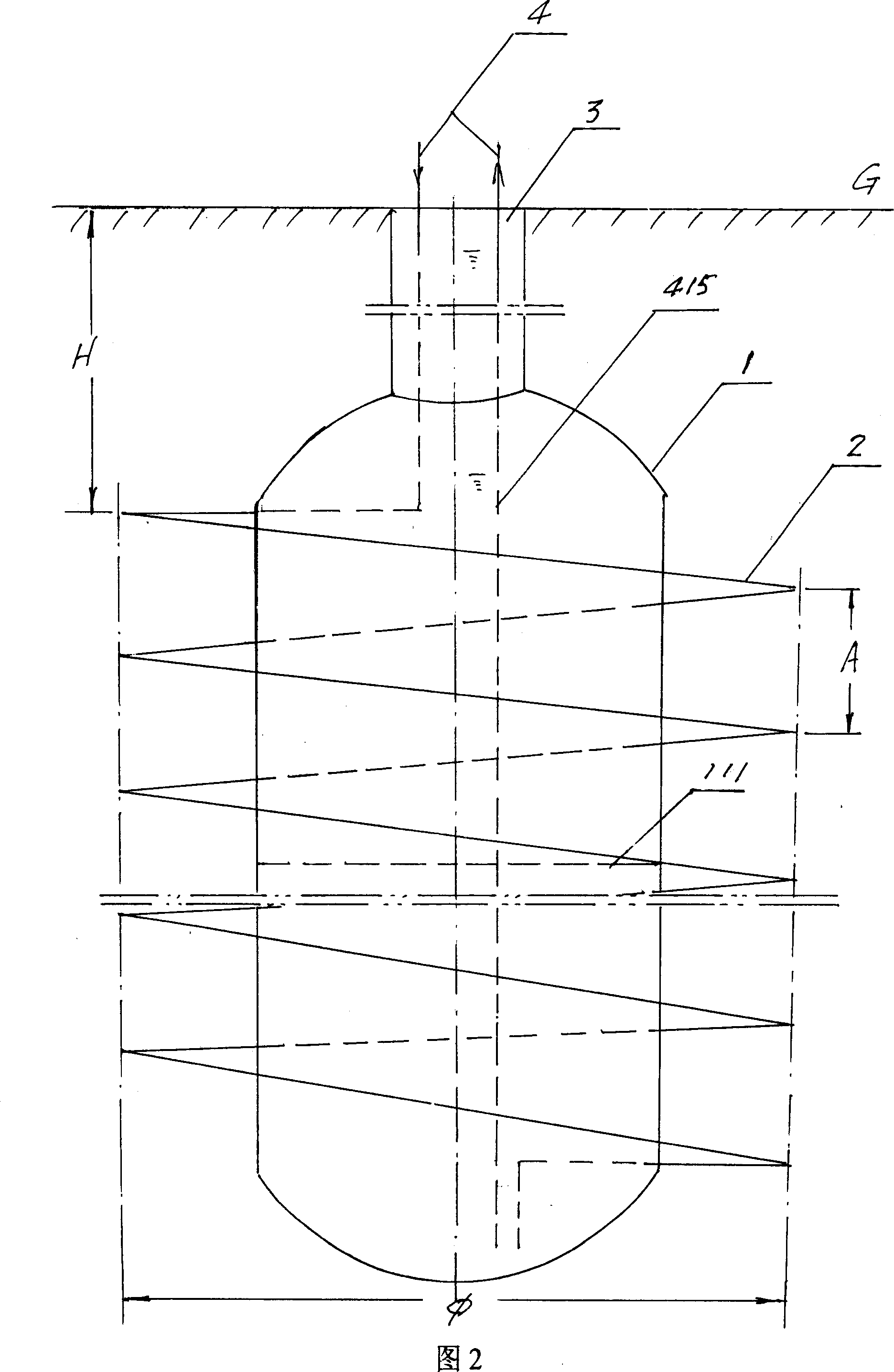

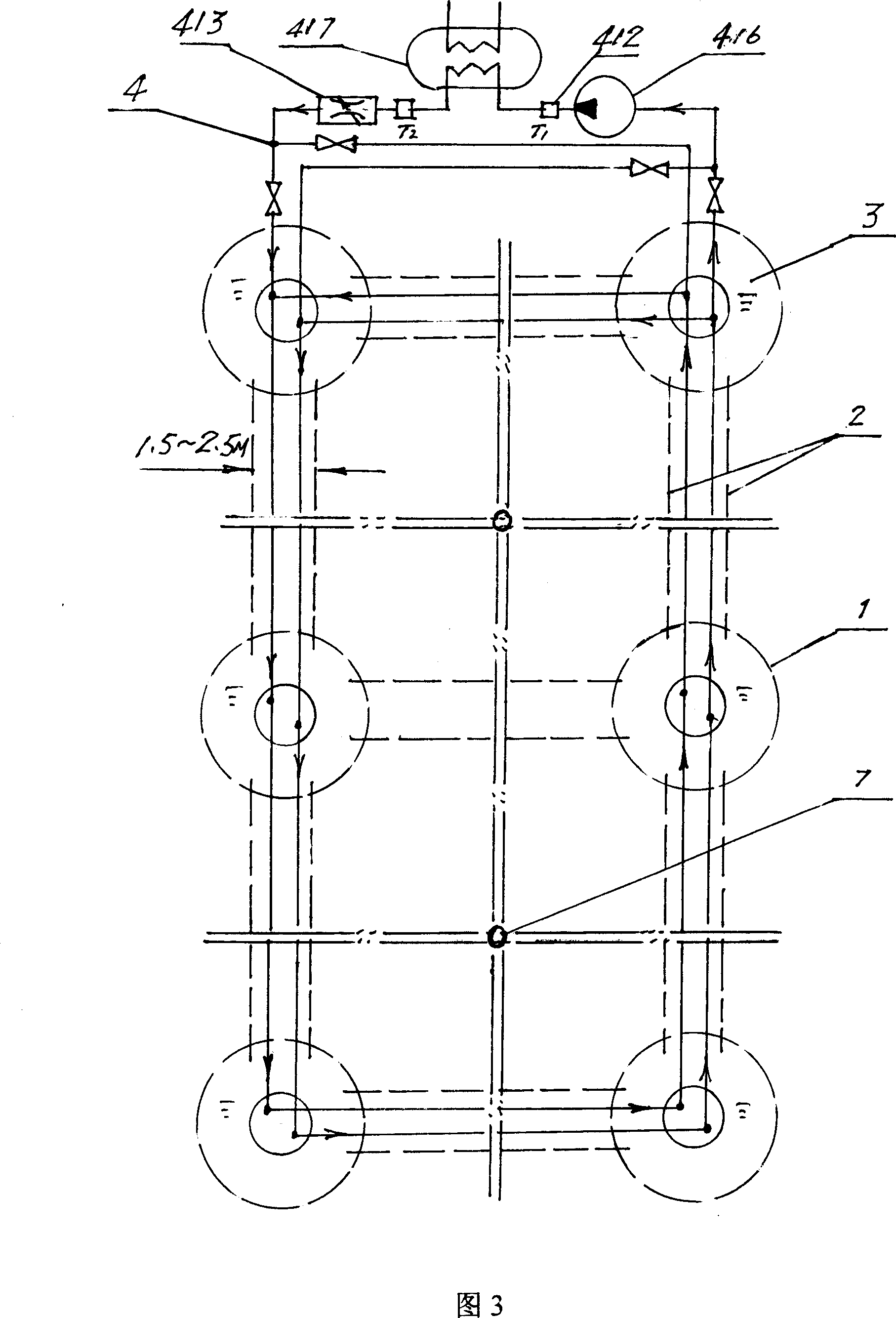

[0042] Embodiment 1: As shown in Figures 1 to 3, one of the embodiments of the circulating geothermal heat exchange type underground energy storage liquid storage of the present invention consists of one or more underground liquid storages 1, Buried heat exchange tube 2, heat carrier medium 3, circulation delivery pipeline 4, manhole 5, hole cover 6, moisturizing seepage pipe 7, energy storage water tank 8, lining solution bag 13, water-absorbing and moisturizing filler 14, etc., among which , the underground liquid reservoir 1 includes a partition plate 111, and the circulation conveying pipeline 4 can be divided into a primary circulation conveying pipeline and a secondary circulation conveying pipeline, the former including a decontamination device 411, a temperature sensor 412, a flow regulating valve 413, a flow rate Meter 414, delivery pipeline 415, delivery pump 416, heat exchange unit 417.

[0043] The circulating geothermal heat exchange type underground energy storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com