Wheel-support rolling bearing unit

A technology for rolling bearings and wheels, which is applied to bearing elements, axles, wheels, etc., can solve the problems of increased resistance to deformation load and deformation, achieve the effect of improving wear resistance and hardness, and improving rolling fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

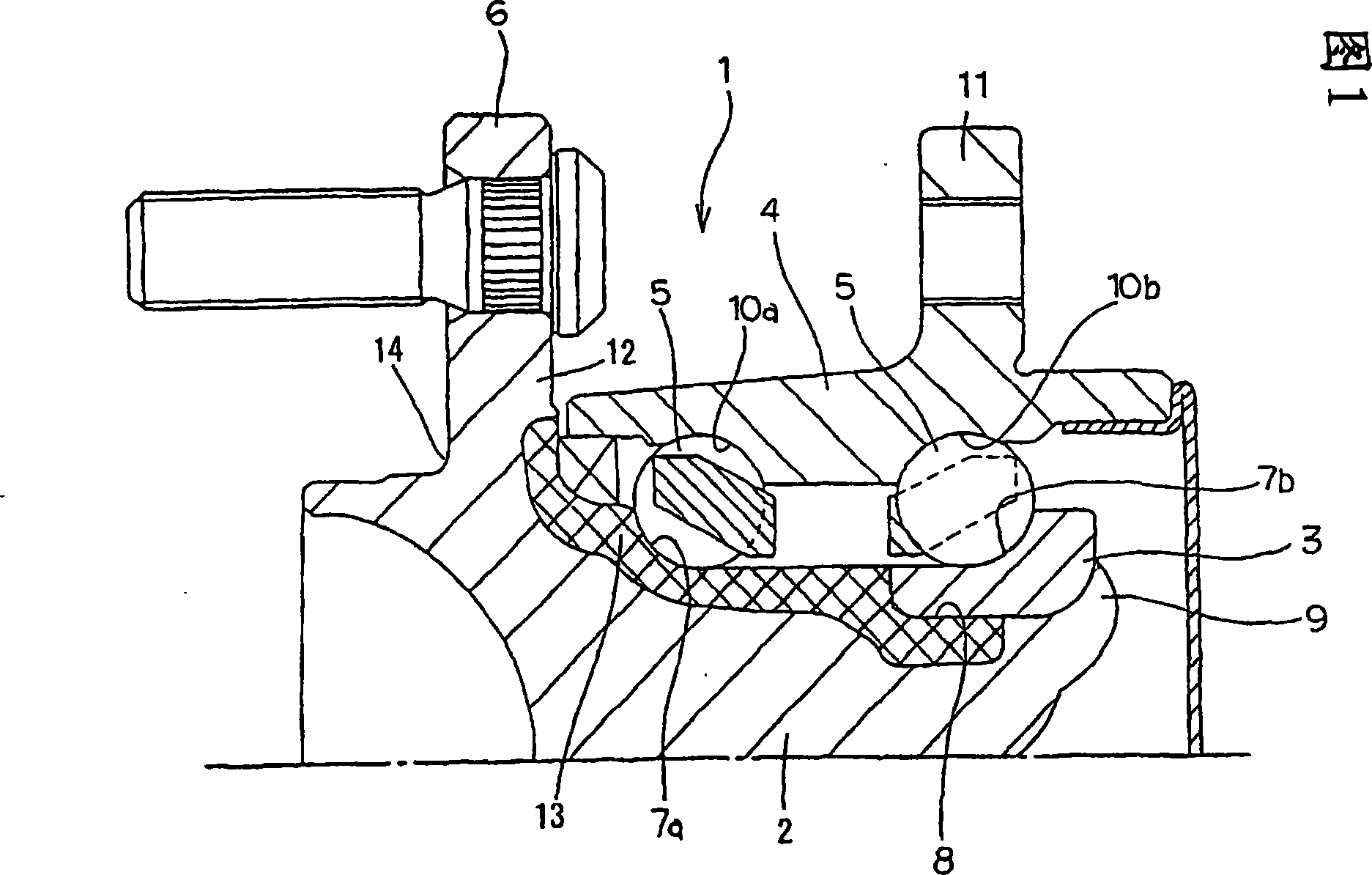

[0236] In the flanged bearing device 1 , since the hub wheel 2 is in a rotating state, a radial load from the road surface is applied to the bearing, and rotational bending stress is generated at the base of the wheel mounting flange 6 . In particular, since the outer root portion 14 of the wheel mounting flange 6 is not subjected to heat treatment such as quenching, rotational bending stress is concentrated, and therefore, there is a risk of damage depending on usage conditions or design conditions.

[0237] On the one hand, as described above, since the weight of the hub 2 is required to be reduced, the thickness of the wheel mounting flange 6 is preferably reduced. However, in order to increase the thickness reduction of the wheel mounting flange 6 , it is necessary to increase the fatigue strength of the root portion 14 on the outer side of the wheel mounting flange 6 .

[0238] On the outer root portion (non-tempered portion) 14 of the wheel mounting flange 6 that is not ...

no. 1 example

[0292] In order to confirm the effects of the present invention, the raw materials shown in Table 7 were processed under various hot forging conditions, the microstructure was confirmed, and the amount of proeutectoid ferrite was measured by image analysis.

[0293] steel type

C

(weight%)

Si

(weight%)

mn

(weight%)

Cr

(weight%)

V

(weight%)

S

(weight%)

S53C

0.53

0.21

0.75

0.17

0

0.017

A1

0.54

0.24

0.79

0.15

0

0.013

A2

0.53

0.22

0.81

0.16

0

0.005

A3

0.45

0.22

0.81

0.16

0

0.013

A4

0.65

0.22

0.81

0.16

0

0.013

A5

0.56

0.24

0.79

0.15

0.08

0.013

B1 ...

no. 2 example

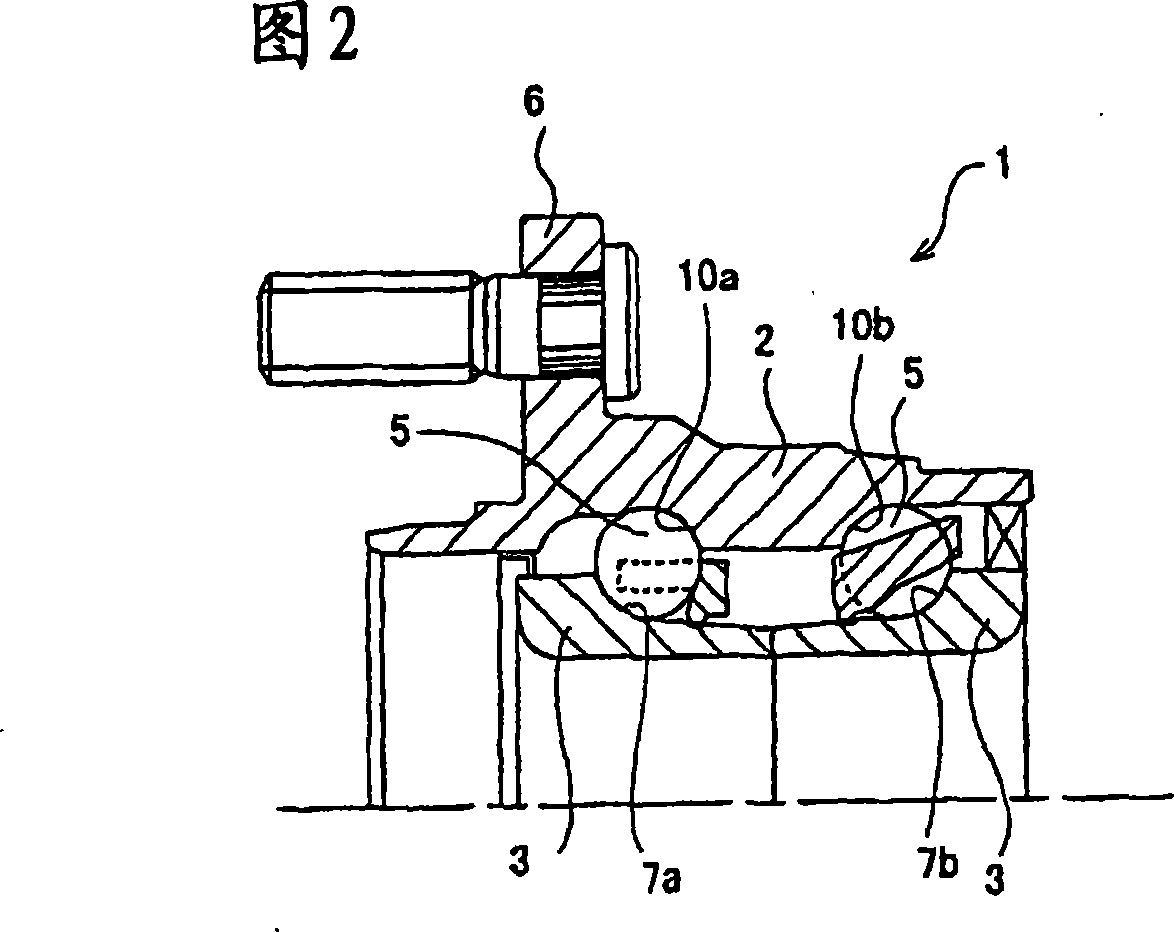

[0324] In order to confirm the effects of the present invention, the following experiments were conducted.

[0325] First, using the rod-shaped raw materials of components A to D in Table 9, each rod was cut, and then formed into a predetermined shape by high-frequency induction heating and hot forging at a temperature of 950 to 1200° C., respectively. Then, forced air cooling or natural cooling, after removal of the oxide film by a shot blasting machine, turning, high-frequency induction hardening and grinding of the raceway surface, the hub ring 2 shown in FIG. 9 is produced.

[0326] In addition, as the hub ring 2, the hub rings in Examples 22 to 30 in Table 10 and Comparative Examples 7 to 11 were prepared. In addition, as the hub wheels 2 of Examples 22 to 30, those subjected to the above-mentioned distribution control of proeutectoid ferrite were used.

[0327] Element

C

(weight%)

Si

(weight%)

mn

(weight%)

Cr

(weight%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com