Method for separating preparing anthocyan monomer from mulberry

An anthocyanin and mulberry technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and medical preparations containing active ingredients, etc., can solve the problems of large separation technology, small separation amount, difficult regeneration and use, etc. Preparation, low preparation cost, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

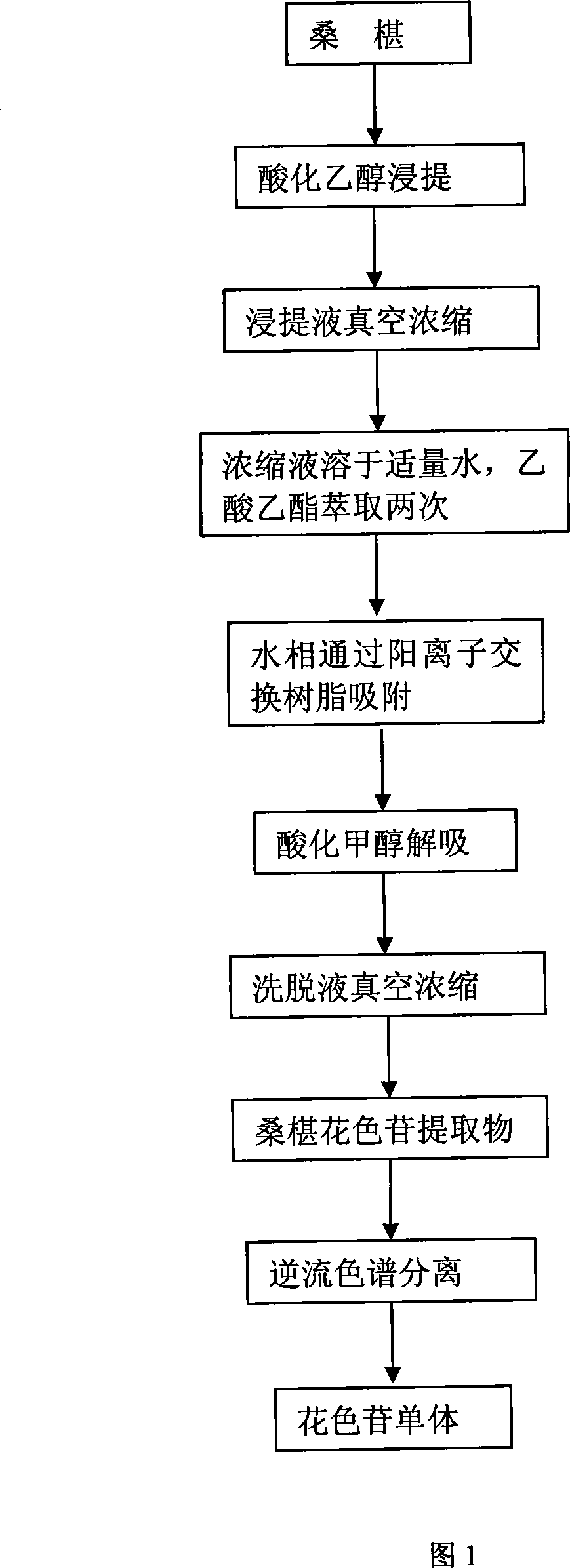

Method used

Image

Examples

Embodiment 1

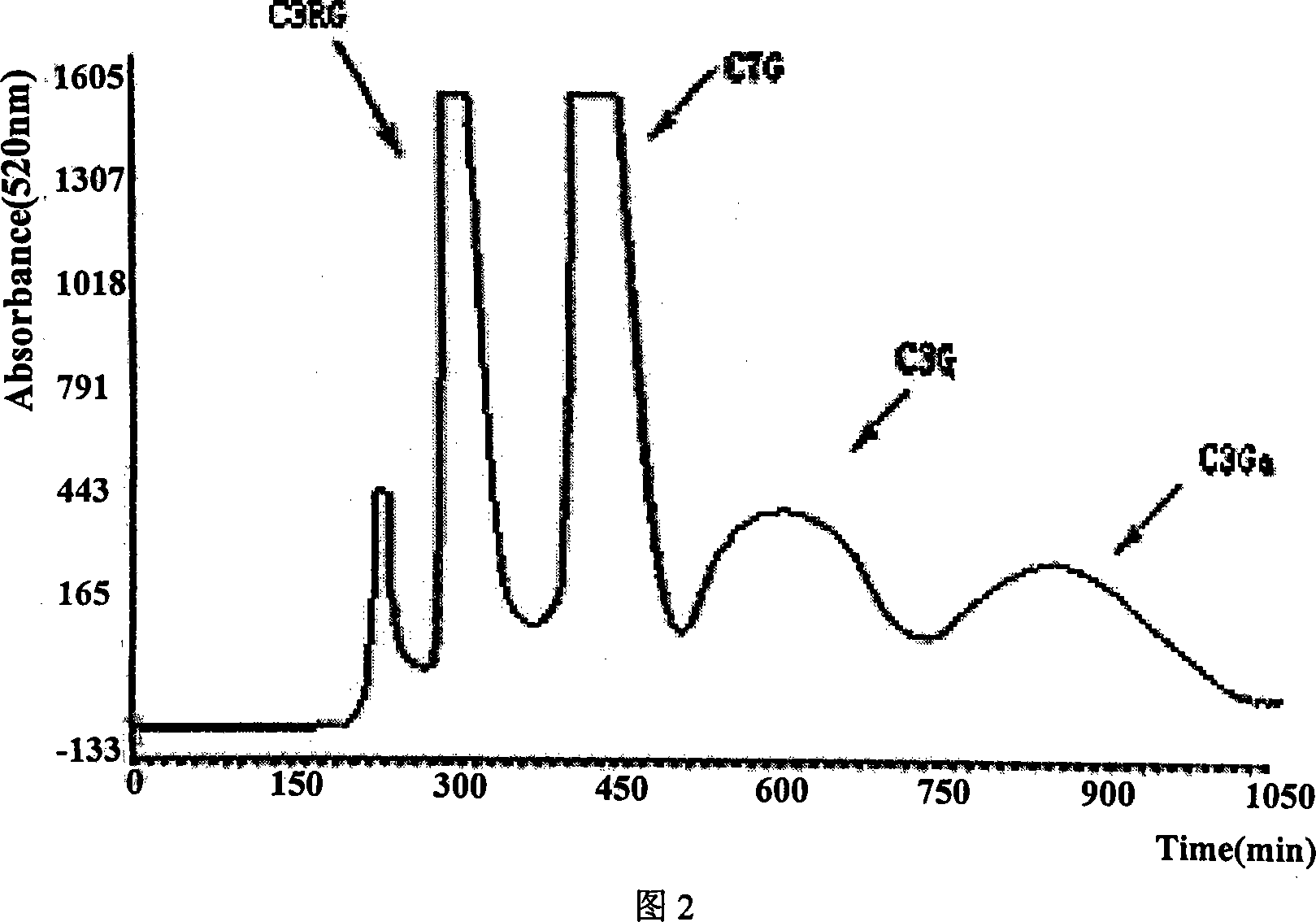

[0041] The solvent system of the present embodiment adopts TBME by volume: acetonitrile: n-butanol: TFA aqueous solution=1:1:3:5, the concentration of TFA aqueous solution is to contain 1 milliliter of TFA in every liter of aqueous solution, and the countercurrent chromatograph is HSCCC-D400 High-speed countercurrent chromatography, the content of anthocyanins in the crude extract of mulberry anthocyanins accounts for about 46%.

[0042] Measure 150ml of TBME, 150ml of acetonitrile, 450ml of n-butanol and 750ml of trifluoroacetic acid aqueous solution, put it in a 2000ml separatory funnel, shake it well, after standing for stratification, put the upper and lower phases into the reagent bottle respectively. The upper phase was injected into the chromatographic column of high-speed countercurrent chromatography at a flow rate of 20ml / min. Turn on the countercurrent chromatograph to 800 revs / min, then pump the sample solution (15ml lower phase solution with 0.6g mulberry anthocya...

Embodiment 2

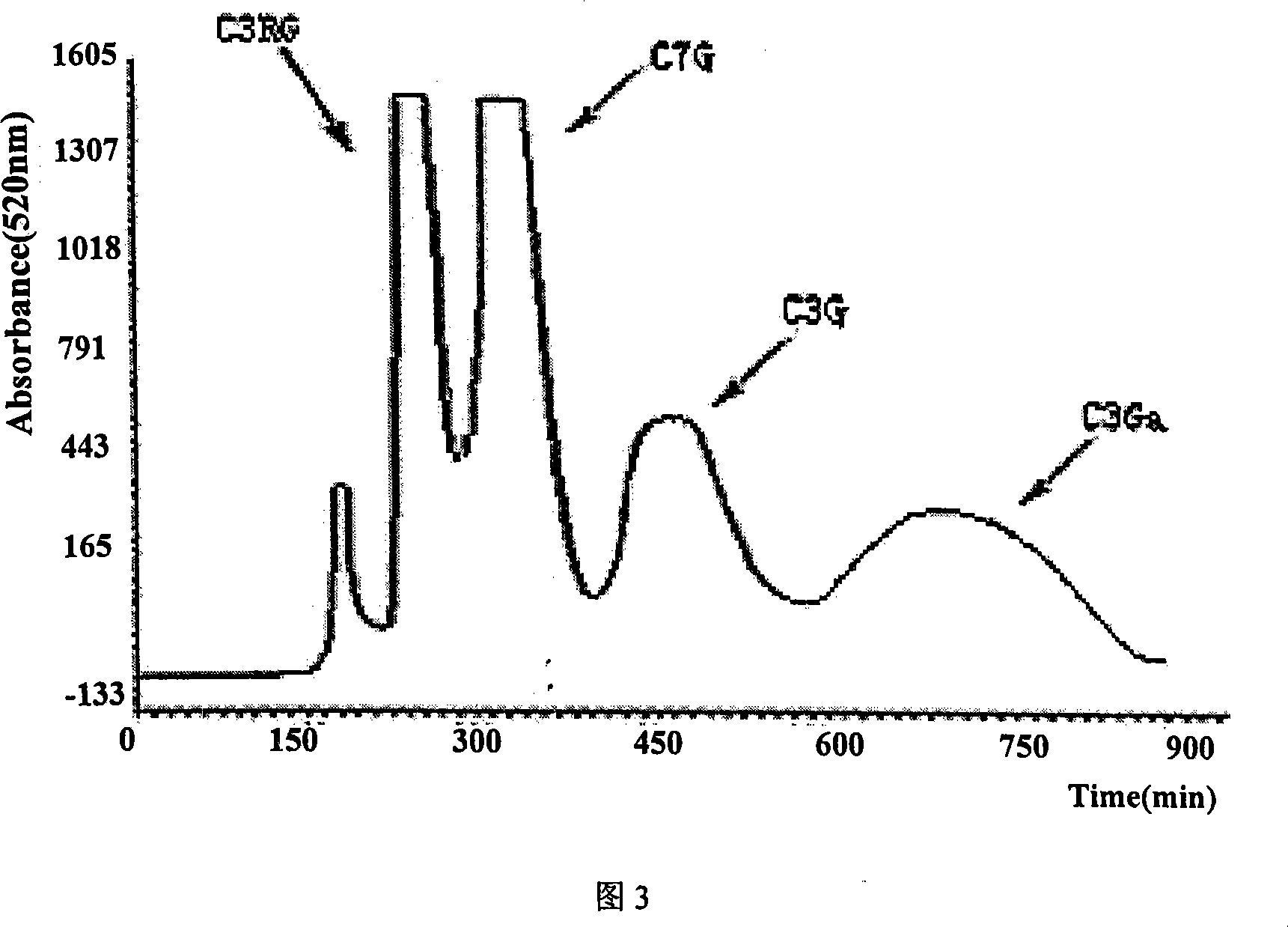

[0044] The solvent system of the present embodiment adopts TBME by volume ratio: acetonitrile: n-butanol: TFA aqueous solution=2: 1: 2.5: 6, the concentration of TFA aqueous solution is to contain 5 milliliters of TFA in every liter of aqueous solution, countercurrent chromatograph is HSCCC-D400 High-speed countercurrent chromatography, the content of anthocyanins in the crude extract of mulberry anthocyanins accounts for about 46%.

[0045]Measure 300ml of TBME, 150ml of acetonitrile, 375ml of n-butanol and 900ml of TFA aqueous solution, put them in a 2000ml separatory funnel, shake them well, and put the upper and lower phases into reagent bottles respectively after standing for stratification. The upper phase was injected into the chromatographic column of high-speed countercurrent chromatography at a flow rate of 20ml / min. Turn on the countercurrent chromatograph to 800 revs / min, then pump the sample solution (15ml lower phase solution with 0.6g mulberry anthocyanin crude ...

Embodiment 3

[0047] The solvent system of the present embodiment adopts TBME by volume ratio: acetonitrile: n-butanol: TFA aqueous solution=1: 1: 3.5: 6, the concentration of TFA aqueous solution is to contain 5 milliliters of TFA in every liter of aqueous solution, countercurrent chromatograph is HSCCC-D1000 High-speed countercurrent chromatography, the content of anthocyanins in the crude extract of mulberry anthocyanins accounts for about 38%.

[0048] Measure 250ml of TBME, 250ml of acetonitrile, 875ml of n-butanol and 1500ml of TFA aqueous solution, put it in a 3000ml separatory funnel, shake it well, after standing for stratification, put the upper and lower phases into reagent bottles respectively. The upper phase was injected into the chromatographic column of high-speed countercurrent chromatography at a flow rate of 40ml / min. Turn on the countercurrent chromatograph to 800 revs / min, then pump the sample solution (40ml lower phase solution with 1.5g mulberry anthocyanin crude extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com