Pole piece feeding device of lithium battery cell piece stacking machine

A stacking machine, lithium battery technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of battery failure, overlapping and adhesion of pole pieces, etc., and achieve the effect of improving separation efficiency and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

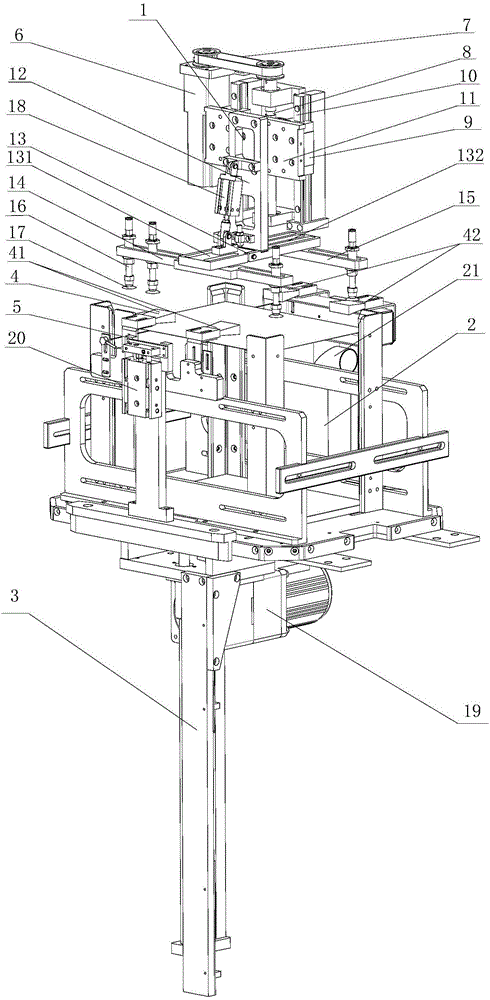

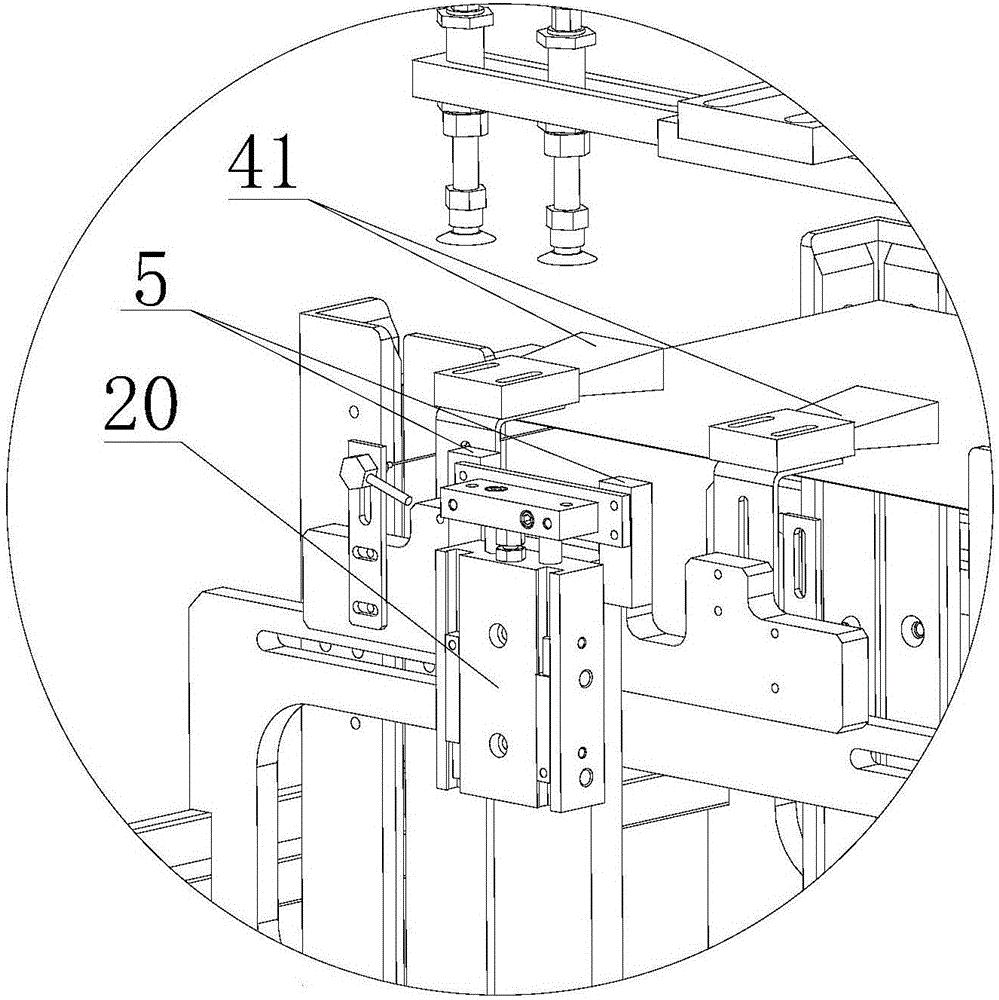

[0018] combine figure 1 with figure 2 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0019] Existing lithium battery cell stacking machines usually do zigzag stacking assembly of positive electrode sheet, negative electrode sheet and diaphragm. Both the positive electrode sheet and the negative electrode sheet use the electrode sheet feeding device, and the device structure is the same.

[0020] Such as figure 1 As shown, a lithium battery cell lamination machine pole piece feeding device includes a piece taking mechanism 1 for grabbing the pole pieces in the material box 2, which is arranged sequentially on the frame from top to bottom, and a pole piece holding mechanism. Material box 2, a jacking mechanism 3 for driving the pole pieces in the material box 2 to move upward, a brush 4 and an ion air knife 5, the brush 4 and the ion air knife 5 are located on the edge of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com