Wave sieve type grain cleaning mechanism

A sieve and wave technology, applied in the direction of sieving, solid separation, grille, etc., can solve the problems of unsatisfactory separation effect of grain and debris, vortex of difficult strength and quantity, cleaning effect and poor quality, etc., to achieve Good separation effect, good quality, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

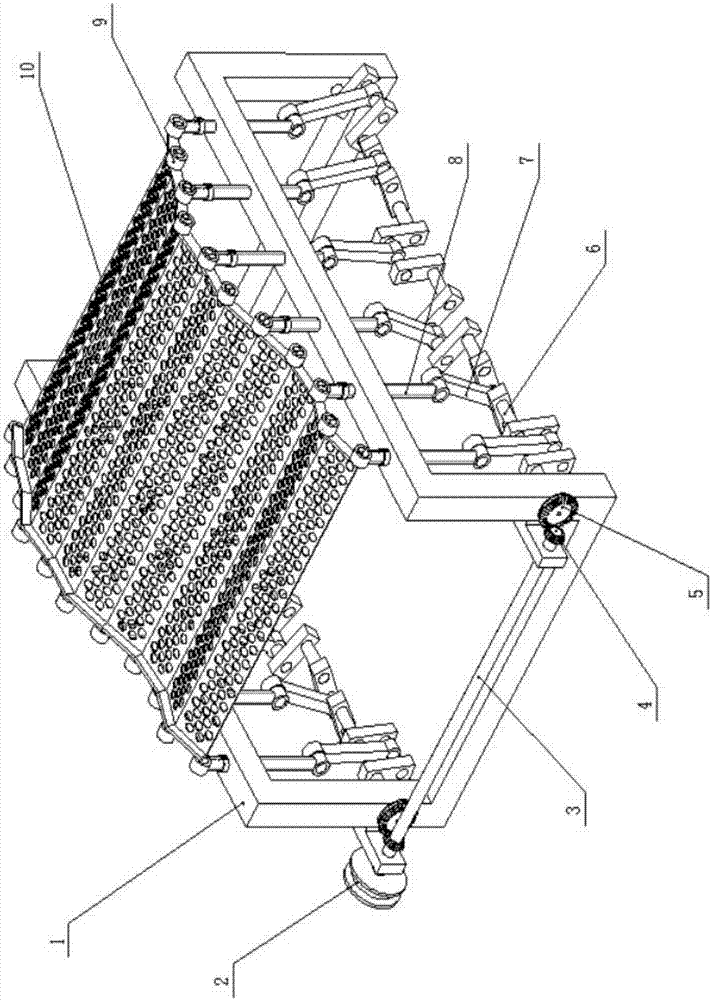

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A wave sieve type grain cleaning mechanism, a drive shaft 3 is rotatably installed on the lower part of the front end or rear end of the frame assembly 1, and the drive pulley 2 and two driving bevel gears 4 are sequentially fixed on the drive shaft 3 , a plurality of length-adjustable push-pull rod assemblies 8 are respectively mated and installed on the upper parts of the left and right sides of the frame assembly 1 that are symmetrical to each other and can move up and down. The crankshafts 6 are respectively installed symmetrically and rotatably on the lower part, and the lower ends of the multiple length-adjustable push-pull rod assemblies 8 on the left and right sides are hingedly connected with the upper ends of the multiple connecting rods 7 on the left and right sides one by one. The lower ends of a plurality of connecting rods 7 on the left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com