Single-crystal production apparatus

A manufacturing device and single crystal technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of metal pollution, pollution, easy scattering of fibers, etc., and achieve the effect of preventing impurity pollution and improving heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

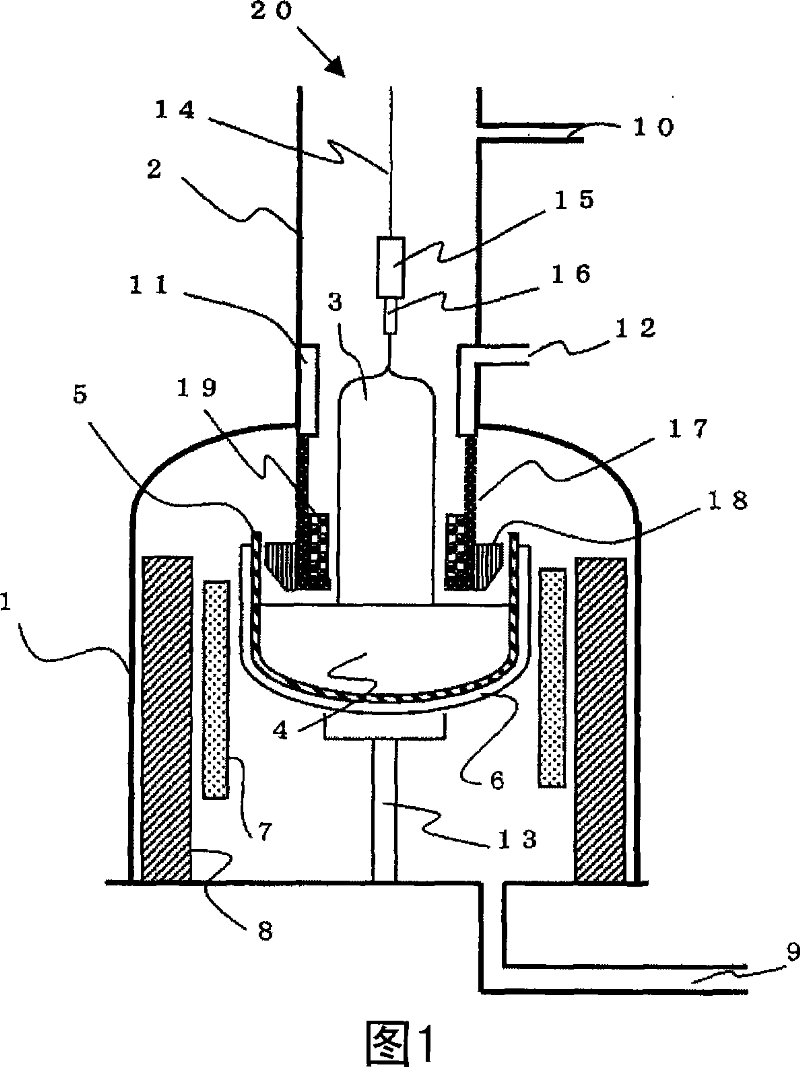

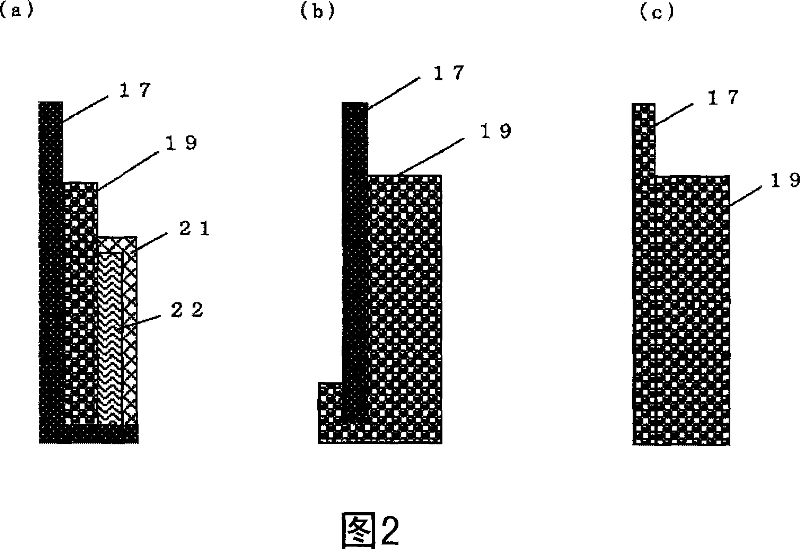

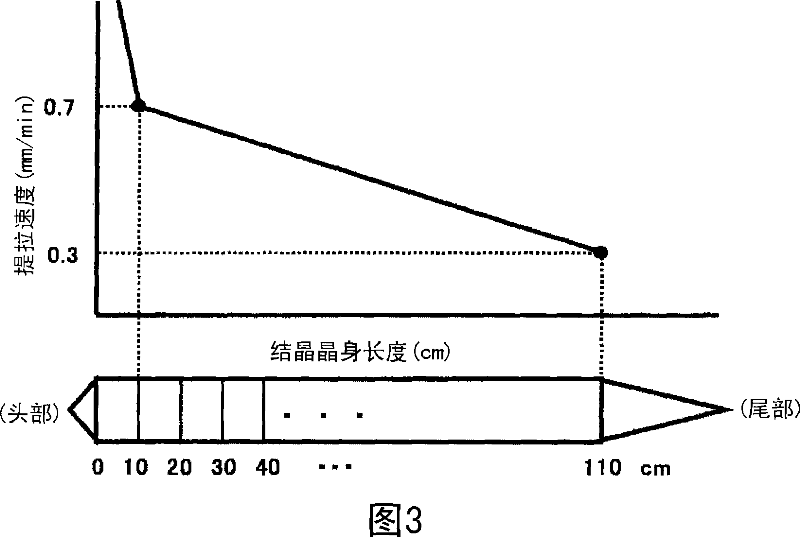

[0065] Using the single crystal manufacturing device 20 shown in Figure 1, 150kg of raw material polycrystalline silicon is placed in a quartz crucible 5 with a diameter of 24 inches (600mm), and pulled by the CZ method with a diameter of 8 inches (200mm) and an orientation , Silicon single crystal with an oxygen concentration of 22-23ppma (ATSM'79). From the ceiling of the pulling chamber 2, in the mode of surrounding the single crystal in the single crystal growth direction, in the inner side of the lower end of the gas straightening cylinder 17 made of graphite hanging down, a gas bubble (a bubble diameter of 30 to 120 μm and a bubble density of 2 μm) is set. ×10 5 piece / cm 3 ~3×10 5 piece / cm 3 ) quartz material 19, and its logarithmic viscosity at 1250° C. is 12 poise, its occupancy rate relative to the inner surface area is 90%, its thickness is 10 mm, and its height is 150 mm. Furthermore, the bubble density contained in the quartz material is calculated by observing...

Embodiment 2

[0088] In addition to using a gas rectifying cylinder, it is arranged inside the lower end of the gas rectifying cylinder 17 in the single crystal manufacturing device 20, which contains bubbles (the diameter of the bubble is 30 ~ 120 μm, the density of the bubble is 5 × 10 4 piece / cm 3 ) of quartz material 19, except that its logarithmic viscosity at 1250° C. is 10 poise, its occupancy to the inner surface area is 90%, its thickness is 10 mm, and its height is 150 mm, it is manufactured using the same single crystal as in Example 1. device, and pull a silicon single crystal with a diameter of 8 inches (200 mm), an orientation , and an oxygen concentration of 22 to 23 ppma (ATSM'79) by the CZ method. Furthermore, as the pulling speed conditions when pulling the single crystal, the same as in Example 1, the pulling speed from the body of the single crystal between 10 cm and 110 cm is in the range of 0.7 mm / min to 0.3 mm / min Inside, it is controlled to gradually reduce the pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com