Phosphamide ester extreme pressure anti-wear additives and preparation and application thereof

An extreme-pressure anti-wear agent, alkyl technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve problems such as low strength of tricresyl phosphate oil film, high activity of di-n-butyl phosphite, and odor , to achieve excellent anti-wear performance, good oil solubility, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

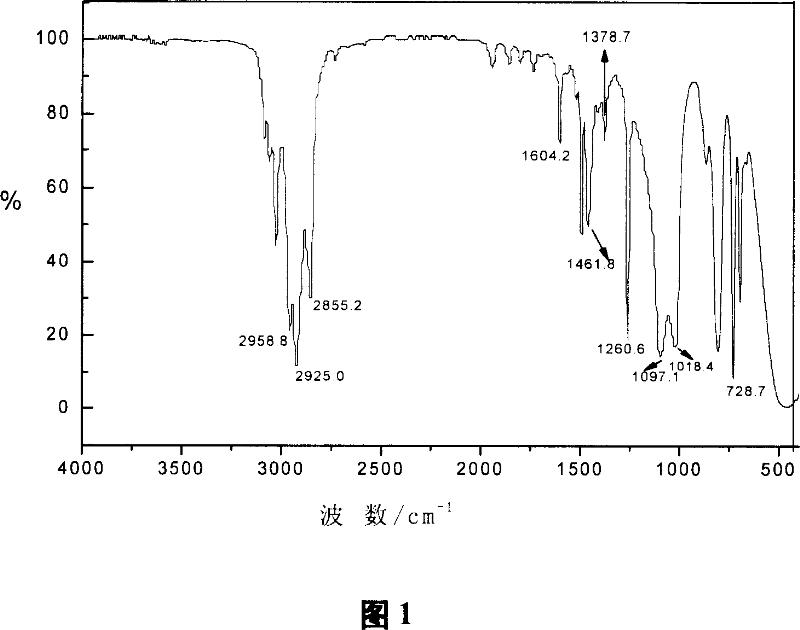

example 1

[0036] Take 0.3mol phosphorus oxychloride and 200ml toluene, stir and add 0.3mol n-octanol at a temperature of 0±5°C, stir and add 0.3mol lauryl alcohol and 0.6mol triethylamine after 3 hours, stir and add 0.33mol hydration after another 3 hours Hydrazine, heat up to 110±5°C for 1 hour to react for 1 hour, wash, dry, and purify. The obtained colorless transparent viscous liquid is the anti-wear additive n-octyl n-dodecylphosphorylhydrazide, code-named A1. Add A1 to N46 base oil at 0.50w%, and evaluate it with a four-ball tester. The results are shown in Table 1;

example 2

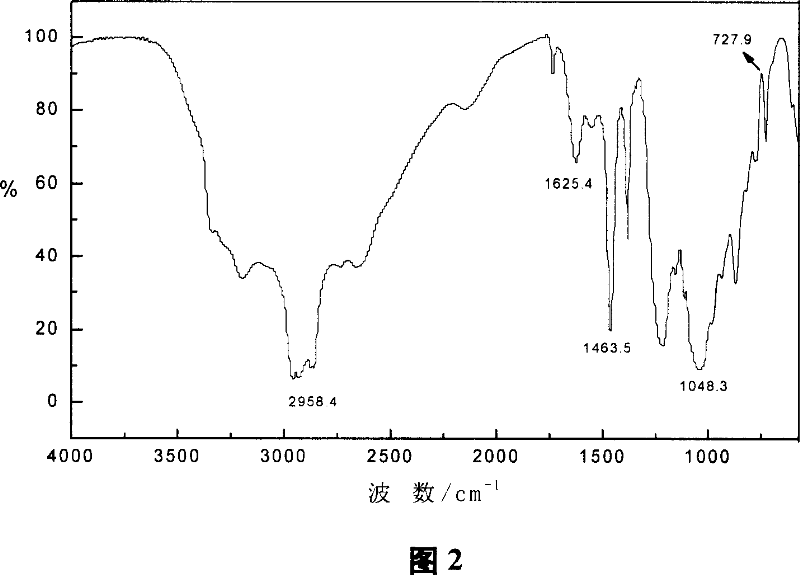

[0038] Take 0.3mol of phosphorus oxychloride and 200ml of tetrahydrofuran, stir and add 0.3mol of isooctyl alcohol at a temperature of 0±5°C, stir and add 0.3mol of isooctyl alcohol and 0.6mol of triethylamine after 3 hours, stir and add 0.33mol of triethylamine after another 3 hours Hydrazine hydrate, after 2 hours, heat up to 110±5°C to react for 1 hour, wash, dry, and purify. The obtained light yellow transparent liquid is the anti-wear additive diisooctylphosphorylhydrazide, code-named A2. A2 was added into N46 base oil at 0.50w%, and evaluated by four-ball tester, and the results are shown in Table 1;

example 3

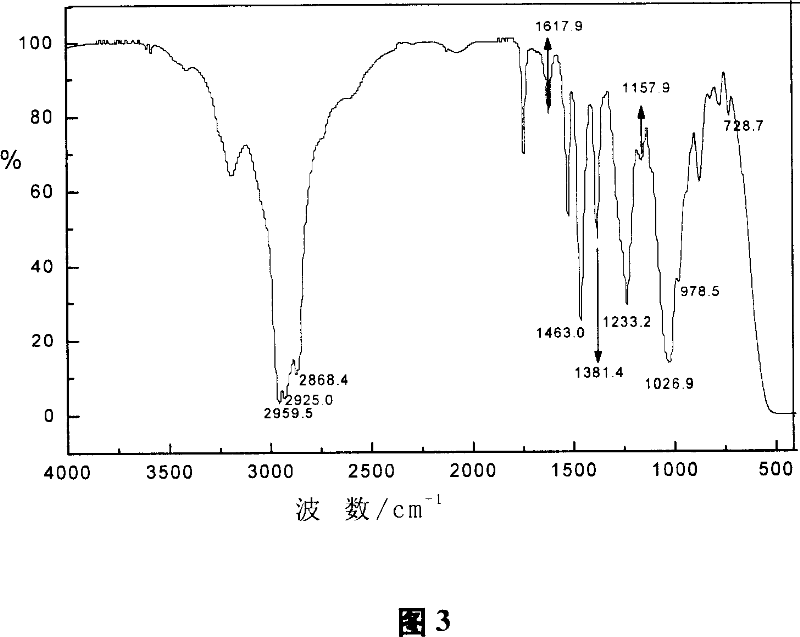

[0040] Take 0.3mol of phosphorus oxychloride and 150ml of ether, stir and add 0.3mol of n-butanol at a temperature of 0±5°C, stir and add 0.3mol of n-butanol and 0.4mol of triethylamine after 3 hours, and then separate after another 3 hours , Evaporate the solvent to obtain the intermediate phosphorus oxychloride. Put phosphorus oxychloride and 150ml toluene into a three-necked flask, add 0.3mol tertiary carbon primary amine (Primene 81-R) with a carbon number of 12, stir and add 0.3mol triethylamine, and heat up to 110±5°C after 2 hours React for 1 hour, wash, dry, and purify. The obtained yellow transparent liquid is the anti-wear additive di-n-butylphosphoryl lauryl ester, code-named A3. A3 was added into N46 base oil at 0.50w%, and evaluated by four-ball testing machine, and the results are shown in Table 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com