Method and apparatus for automatically measuring fibre curling performance

A technology of automatic testing and testing device, applied in textile testing, using stable tension/pressure to test material strength, material inspection products, etc. The effect of reducing human error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

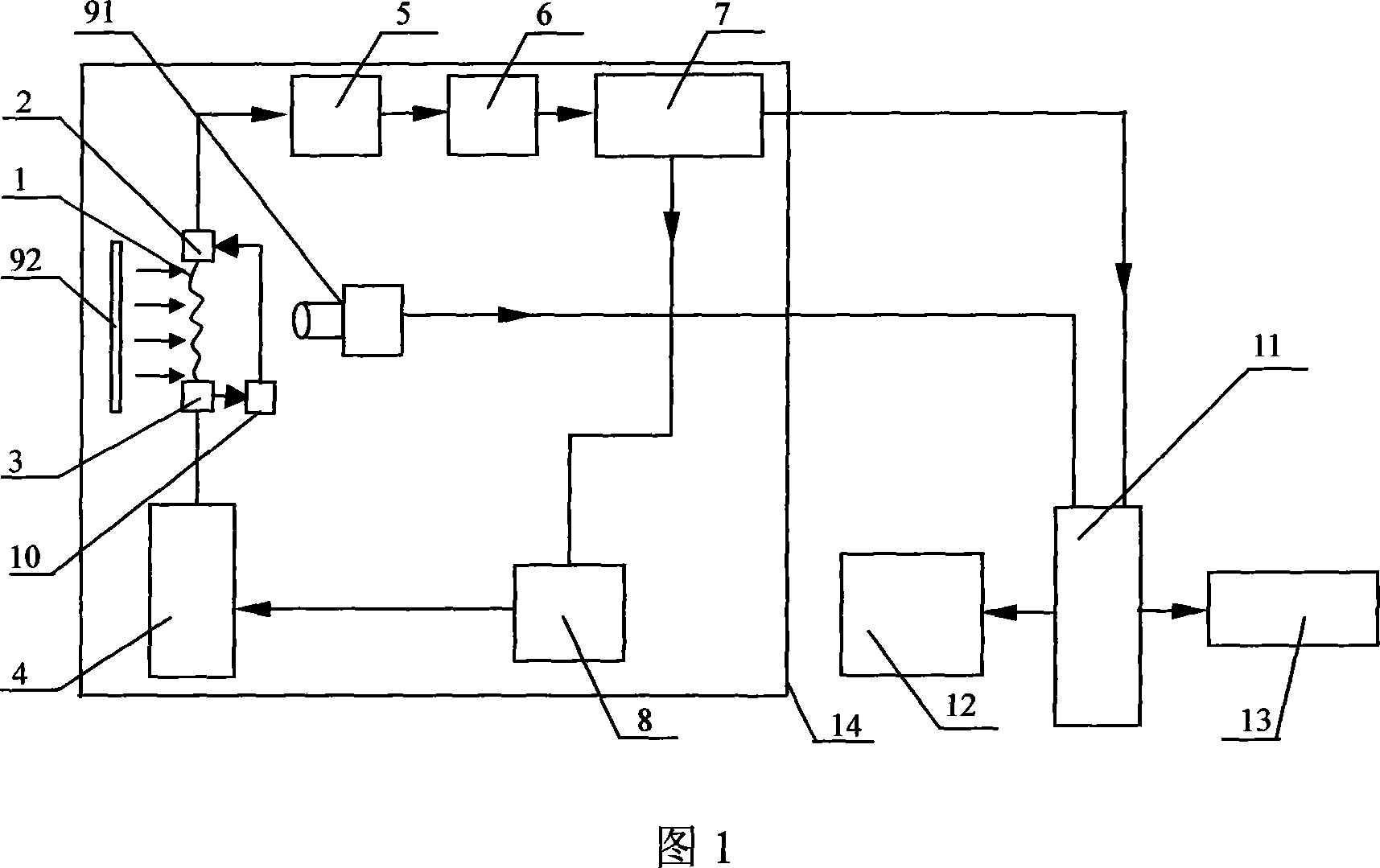

[0040] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, and Fig. 8, the present invention provides an automatic fiber crimp performance test method and test device for automatic fiber test Sample crimp rate, fiber sample crimp elasticity and fiber sample crimp number.

[0041] An automatic test method for fiber crimp performance, which is characterized in that it is implemented as follows:

[0042] [1] First turn on the power switch 14201 of the automatic fiber crimp performance test device and the power switch of the computer 11, and warm up for half an hour;

[0043] [2] According to the linear density unit dtex of fiber sample 1, according to the national standard "GB / T14338-1993 synthetic fiber crimp performance test method", determine the light load unit cN used in fiber sample 1 test, and its value is 0.0018cN / dtex calculation and heavy load unit cN, such as vinylon, nylon, polypropylene, and chlorinated fiber, its value is calculated as 0.05cN / dtex, poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com