Pretreatment and pretreatment solution for direct porous metallizing printing IC board

A printed circuit board and hole metallization technology, which is applied in the field of pretreatment solution and preparation of printed circuit boards, can solve the problems of low adhesion strength of the metal coating on the hole wall, difficult quality control, unstable production, etc., and achieve economic benefits And environmental protection is significant, the production process is shortened, and the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

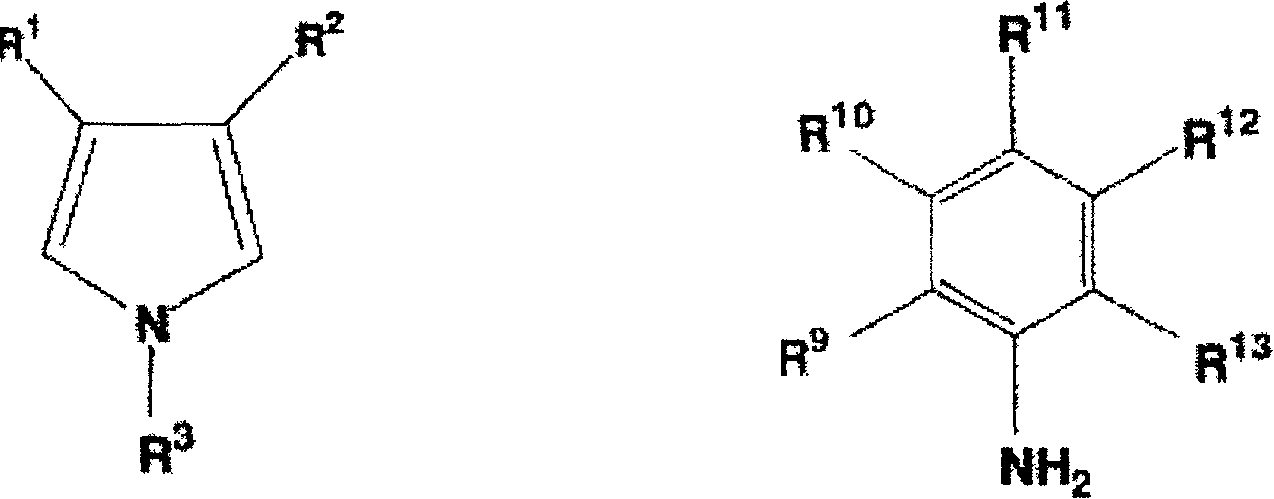

[0018] [Example 1] A pyrrole / polyvinyl alcohol conductive polymer colloid doped with sulfate anions was synthesized according to the following method.

[0019] A specific synthesis example is to dissolve 0.85g (polyvinyl alcohol, analytically pure) in 500ml of warm water at 30°C, then add 7.0g of the oxidizing agent ammonium persulfate and 32.2g of sodium sulfate as an impurity, add water to dilute to 1L, and stir Add 5ml of pyrrole under the condition of , and continue to stir for more than 12 hours to obtain a polymer of pyrrole. The polymer is separated with a high-speed centrifuge (rotating speed is 16000 rpm), and the yellow liquid above is removed to obtain the following black pyrrole polymer. , After washing several times with ion-exchanged water, disperse it in 50ml of water with ultrasonic waves, and obtain a pyrrole polymer colloid solution doped with sulfate ions. The colloidal solution was observed with an electron microscope, and the particle diameter of the polym...

Embodiment 2

[0020] [Example 2] A 3-methylpyrrole / polyvinyl alcohol conductive polymer colloid doped with sulfate anions was synthesized according to the following method.

[0021] A specific synthesis example is to dissolve 0.85g (polyvinyl alcohol, analytically pure) in 500ml of warm water at 50°C, then add 7.0g of the oxidizing agent ammonium persulfate and 32.2g of sodium sulfate as an impurity, add water to dilute to 1L, and stir Add 5ml of 3-methylpyrrole under the condition of , continue to stir for 12 hours, obtain the polymer of 3-methylpyrrole, this polymer is separated with high-speed centrifuge (rotating speed is 16000 rpm), remove the yellow liquid above, Obtain the following black pyrrole polymer, after washing several times with ion-exchanged water, disperse it in 50ml of water with ultrasonic wave, promptly obtain the colloidal solution of the 3-methylpyrrole polymer doped with sulfate ion, this colloidal solution passes through Observed with an electron microscope, the par...

Embodiment 3

[0022] [Example 3] A conductive polymer colloid of polyaniline / polyvinylpyrrolidone doped with perchlorate anions was synthesized according to the following method.

[0023] After adding 0.05g of polyvinylpyrrolidone and 1.40g of perchloric acid into 25ml of deionized water respectively, they were dissolved, and under stirring conditions, 1.25ml of aniline was slowly added, and the prepared ammonium persulfate solution was added dropwise in the solution (weighing Take 3.14g of ammonium persulfate and dissolve it in 25ml of deionized water), and add it within 30min. Stir and react for 6 hours, filter with suction, wash with 1mol / L HCl, then wash to neutral with deionized water, place the product in 50ml deionized water, and after ultrasonic dispersion, obtain the polyaniline / Conductive polymer colloid of polyvinylpyrrolidone. The colloidal solution was observed with an electron microscope, and the particle diameter of the polymer was about 150nm. In addition, 50 μL of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com