Active cathode and its production

An active cathode, cathode technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of complex manufacturing process and unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

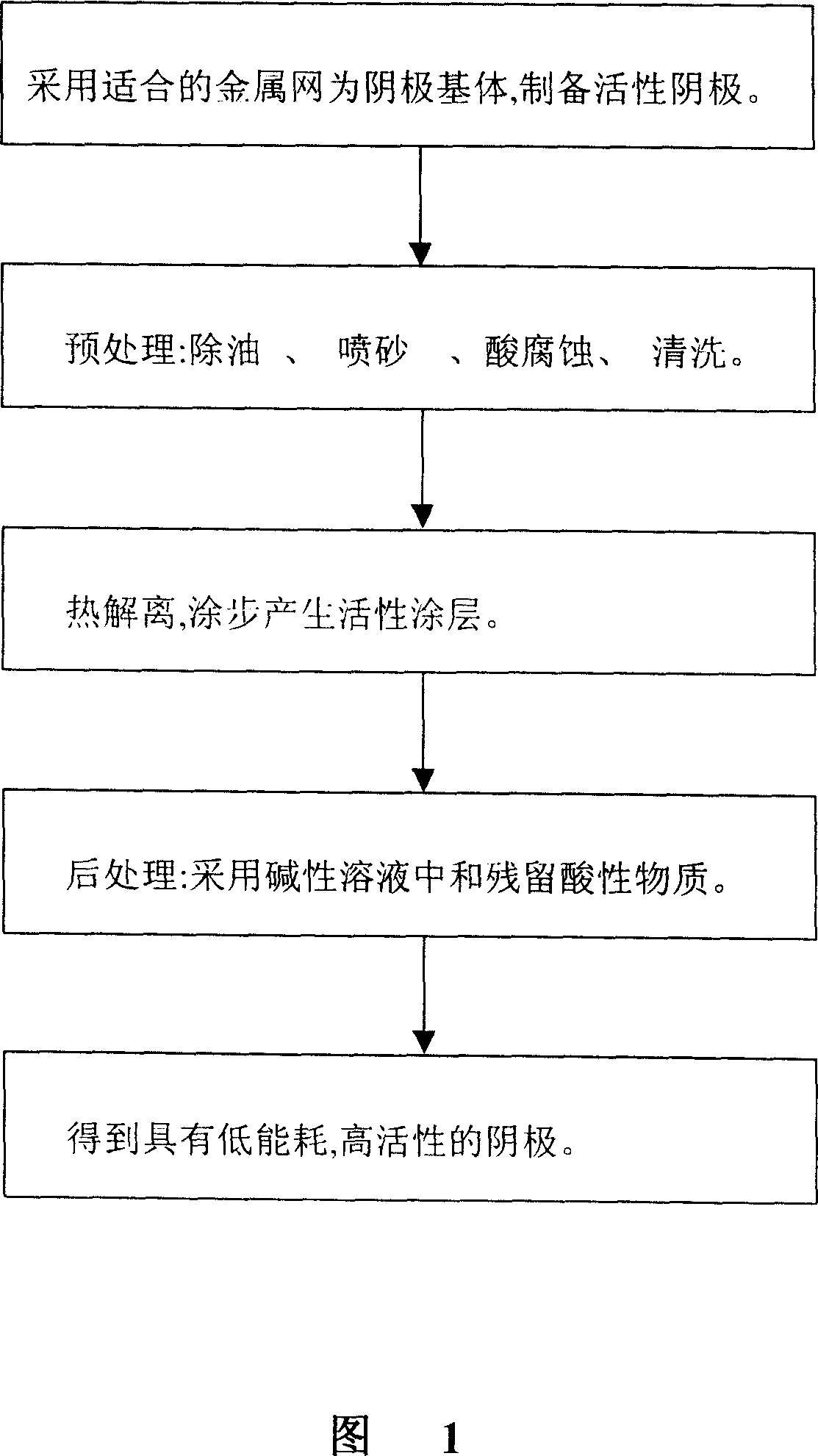

Method used

Image

Examples

Embodiment 1

[0056] Use a degreasing agent to remove the oil stain on the surface of the woven nickel mesh (substrate) and sandblasting to roughen the surface, and its roughness can be directly observed under a microscope. Then carry out annealing treatment with annealing temperature of 500°C for 2 hours. After annealing, keep the temperature at 70°C in 220 g / L sulfuric acid solution for 5 minutes. Take out the metal mesh and rinse with water to remove residual acid. The samples were then activated with metal oxides obtained by thermally decomposing coatings of the following composition in a furnace:

[0057] Nickel Chloride 50 g / L

[0058] Ruthenium trichloride 200 g / L

[0059] Hydrochloric acid 50 g / L

[0060] Lanthanum Chloride 25 g / L

[0061] After drying at 20°C for 30 minutes, the samples were heated in an oven at 500°C to 600°C for 10 minutes, burned, and then cooled to room temperature.

[0062] The above steps are repeated 5-20 times to obtain a surface covering layer with an ...

Embodiment 2

[0069] Use a degreasing agent to remove the oil stain on the surface of the expanded nickel mesh (substrate) and sandblasting to make the surface rough, and its roughness can be directly observed under a microscope. Then perform annealing treatment, the annealing temperature is 400°C, the time is 2 hours, after annealing, heat it to 80°C in 300 g / L sulfuric acid solution and place it for 20 minutes, take out the metal mesh, rinse it with clean water, and remove the residual acid solution. The samples were then activated with metal oxides obtained by thermally decomposing coatings of the following composition in a furnace:

[0070] Nickel Chloride 25 g / L

[0071] Cerium Chloride 25 g / L

[0072] Ruthenium trichloride 250 g / L

[0073] Hydrochloric acid 70 g / L

[0074] Oxalic acid 50 g / L

[0075] After drying at 40°C for 10 minutes, the samples were heated in an oven at 500°C to 600°C for 15 minutes and then cooled to room temperature.

[0076] The above steps are repeated 5-...

Embodiment 3

[0084] Use a degreasing agent to remove the oil stain on the surface of the drilled stainless steel mesh (substrate) and sandblasting to roughen the surface, and its roughness can be directly observed under a microscope. Then perform annealing treatment, the annealing temperature is 650°C, the time is 1.5 hours, after annealing, heat to 80°C in 200 g / L hydrochloric acid solution and let it stand for 30 minutes, take out the metal mesh, rinse it with clean water, and remove the residual acid solution. The samples were then activated with metal oxides obtained by thermally decomposing coatings of the following composition in a furnace:

[0085] Nickel Chloride 25 g / L

[0086] Cerium Chloride 25 g / L

[0087] Ruthenium trichloride 200 g / L

[0088] Hydrochloric acid 100 g / L

[0089] After drying at 40°C for 20 minutes, the samples were heated in an oven at 400°C to 500°C for 30 minutes and then cooled to room temperature.

[0090] The above steps are repeated 5-20 times to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com