Method for for preparing cadmiumsulfide quantum dot sensitized porous titanium dioxide photoelectrode

A porous titanium dioxide and quantum dot sensitization technology, which is applied in circuits, capacitors, electrical components, etc., can solve the problems of poor battery stability, poor crystallization performance of quantum dots, and low photoelectric conversion efficiency, and achieve good crystallization performance, stability and Improvement of photoelectric conversion performance, good light absorption and effect of photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 5mmol lauryl polyoxyethylene ether, heat it in a water bath to melt, add 10ml n-butanol and 25ml cyclohexane to obtain a mixed solution, then add 2mmol cadmium nitrate and 6mmol thiourea to the mixed solution, and stir vigorously to make It dissolves; deionized water is then added to form a microemulsion;

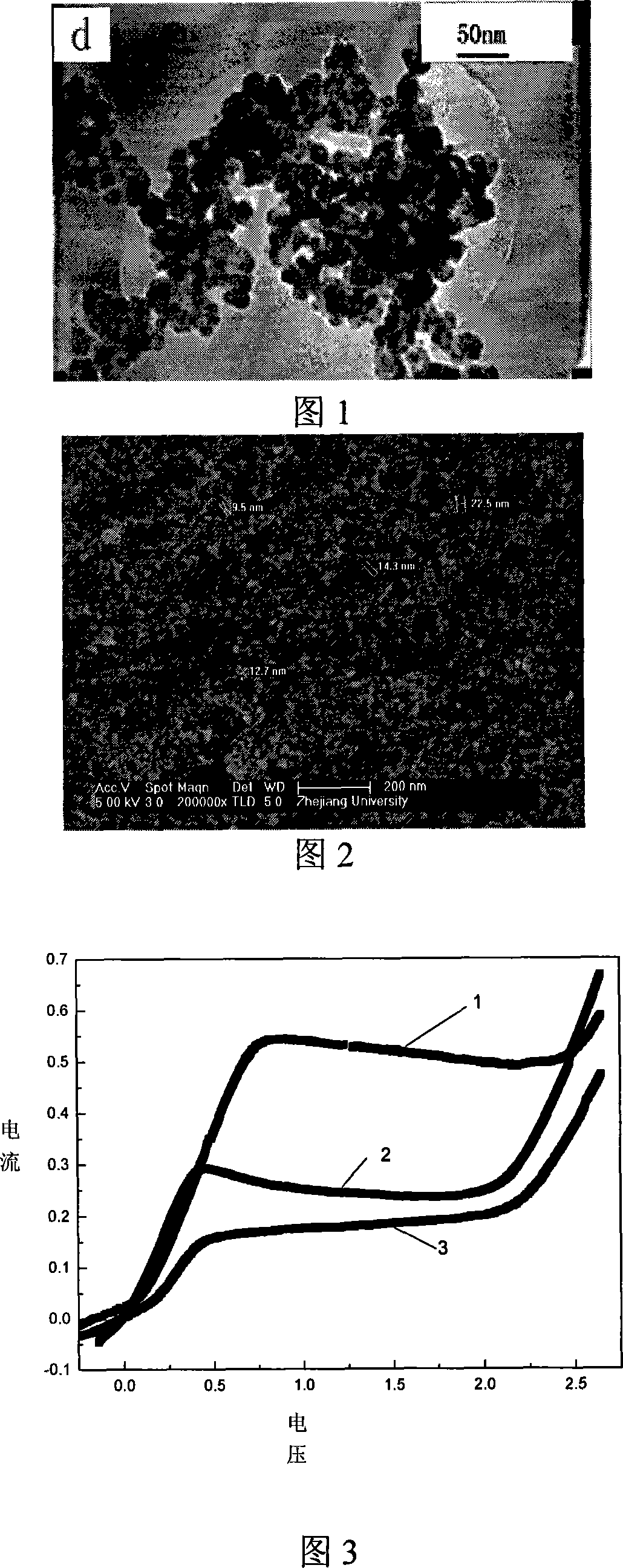

[0018] (2) Pour the prepared microemulsion into a reaction kettle and react at 120°C for 8h; the reaction product is repeatedly washed with ethanol to remove excess surfactant, and the product is vacuum-dried at 60°C for 12h to obtain a bright yellow Powdered samples. The TEM photo of the sample is shown in Figure 1. It can be seen from the photo that the shape of the particles is regular, and the particle size is below 10nm. Pour alcohol into the powder sample to form an alcohol solution of cadmium sulfide quantum dots;

[0019] (3) 50ml of isobutyl titanate was added dropwise to 300ml of 0.1M nitric acid solution at room temperature, stirred vigorously,...

Embodiment 2

[0024] (1) Weigh 5mmol of polyoxyethylene lauryl ether, heat it in a water bath to melt, add 15ml of n-butanol and 30ml of cyclohexane to obtain a mixed solution, then add 2mmol of cadmium nitrate and 8mmol of thiourea to the mixed solution, and stir vigorously Make it dissolve; then add deionized water to form a microemulsion;

[0025] (2) Pour the prepared microemulsion into a reaction kettle and react at 200°C for 5h; wash the reaction product repeatedly with ethanol to remove excess surfactant, and dry the product in vacuum at 60°C for 12h to obtain a bright yellow powder sample. Pour alcohol into the powder sample to form an alcohol solution of cadmium sulfide quantum dots;

[0026] (3) prepare titanium dioxide film with embodiment 1;

[0027] (4) Soak the porous titanium dioxide film in the alcohol solution of oxalic acid and thioglycolic acid for 24h, the molar concentration of oxalic acid in the solution is 2mmol / L, and the molar concentration of thioglycolic acid is...

Embodiment 3

[0029] (1) take by weighing 5mmol sodium dodecylbenzene sulfonate, heating in a water bath makes it melt, add 5ml n-butanol, 15ml hexanaphthene, obtain mixed solution, then add 3mmol cadmium nitrate and 6mmol thiourea in mixed solution, Stir vigorously to dissolve; then add deionized water to form a microemulsion;

[0030] (2) Pour the prepared microemulsion into a reaction kettle and react at 100° C. for 10 h. The reaction product was repeatedly washed with ethanol to remove excess surfactant, and the product was vacuum-dried at 60° C. for 12 hours to obtain a bright yellow powder sample. Pour alcohol into the powder sample to form an alcohol solution of cadmium sulfide quantum dots;

[0031] (3) prepare titanium dioxide film with embodiment 1;

[0032] (4) Soak the porous titanium dioxide film in the alcohol solution of oxalic acid and thioglycolic acid for 24h, the molar concentration of oxalic acid in the solution is 2mmol / L, and the molar concentration of thioglycolic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com