Glass-glass composite optical wave guide

A composite light and glass technology, applied in the field of optical waveguide, can solve the problem that the function of the functional glass substrate 2 cannot be fully exerted, and achieve the effects of multi-functionality, large design and production, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

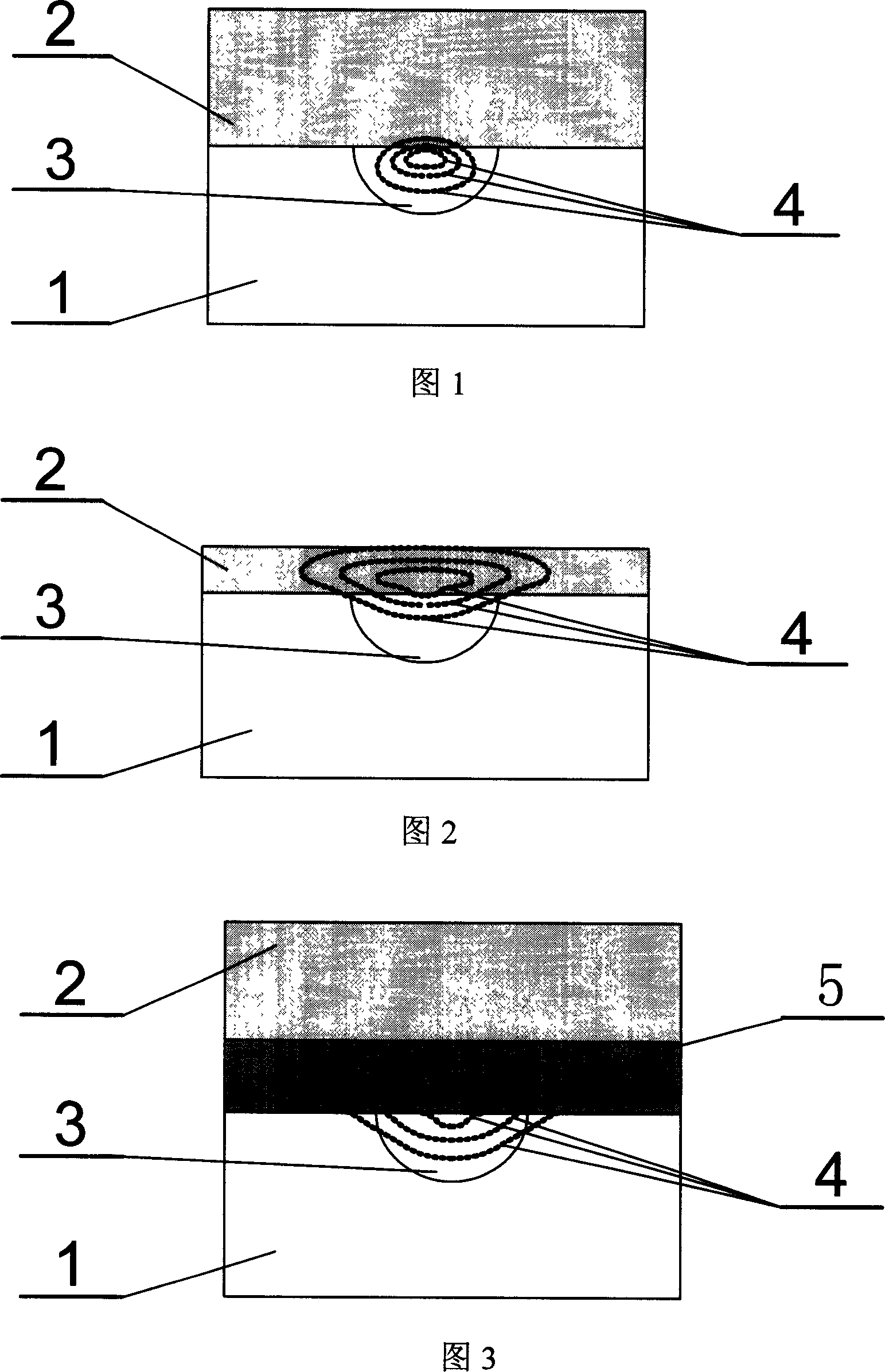

[0024] Embodiment 1: Composite optical waveguide structure see Figure 3, the main process steps

[0025] The glass substrate 1 is made of silicate optical glass material, and the functional glass substrate 2 is made of phosphate glass doped with rare earth. The main manufacturing steps of the glass-glass composite optical waveguide structure:

[0026] (A) Preparation of light guide region 3 on glass substrate 1

[0027] ·Using microfabrication technology to fabricate strip-shaped optical waveguide masks on glass substrates to obtain ion-exchange windows with a width of the order of microns;

[0028] ·Molten salt ion exchange process is used to make strip optical waveguide, and the ion exchange temperature is 300-400°C;

[0029] • Annealing of optical waveguides.

[0030] (B) Preparation of light confinement region 3 on functional glass substrate 2

[0031] · Fabricate the light confinement region 5 on the functional glass substrate 2 by using molten salt ion exchange techn...

Embodiment 2

[0034] Embodiment 2: The composite optical waveguide structure is shown in Figure 4, the main process steps

[0035] The glass substrate 1 is made of silicate optical glass material, and the functional glass substrate 2 is made of phosphate glass doped with rare earth. The main manufacturing steps of the glass-glass composite optical waveguide structure:

[0036] (A) Preparation of light guide region 3 on glass substrate 1

[0037] ·Using microfabrication technology to fabricate strip-shaped optical waveguide masks on glass substrates to obtain ion-exchange windows with a width of the order of microns;

[0038] ·Molten salt ion exchange process is used to make strip optical waveguide, and the ion exchange temperature is 300-400°C;

[0039] • Annealing of optical waveguides.

[0040] (B) Preparation of light confinement region 3 on functional glass substrate 2

[0041] ·Using microfabrication technology to fabricate the mask of the strip optical waveguide on the glass subst...

Embodiment 3

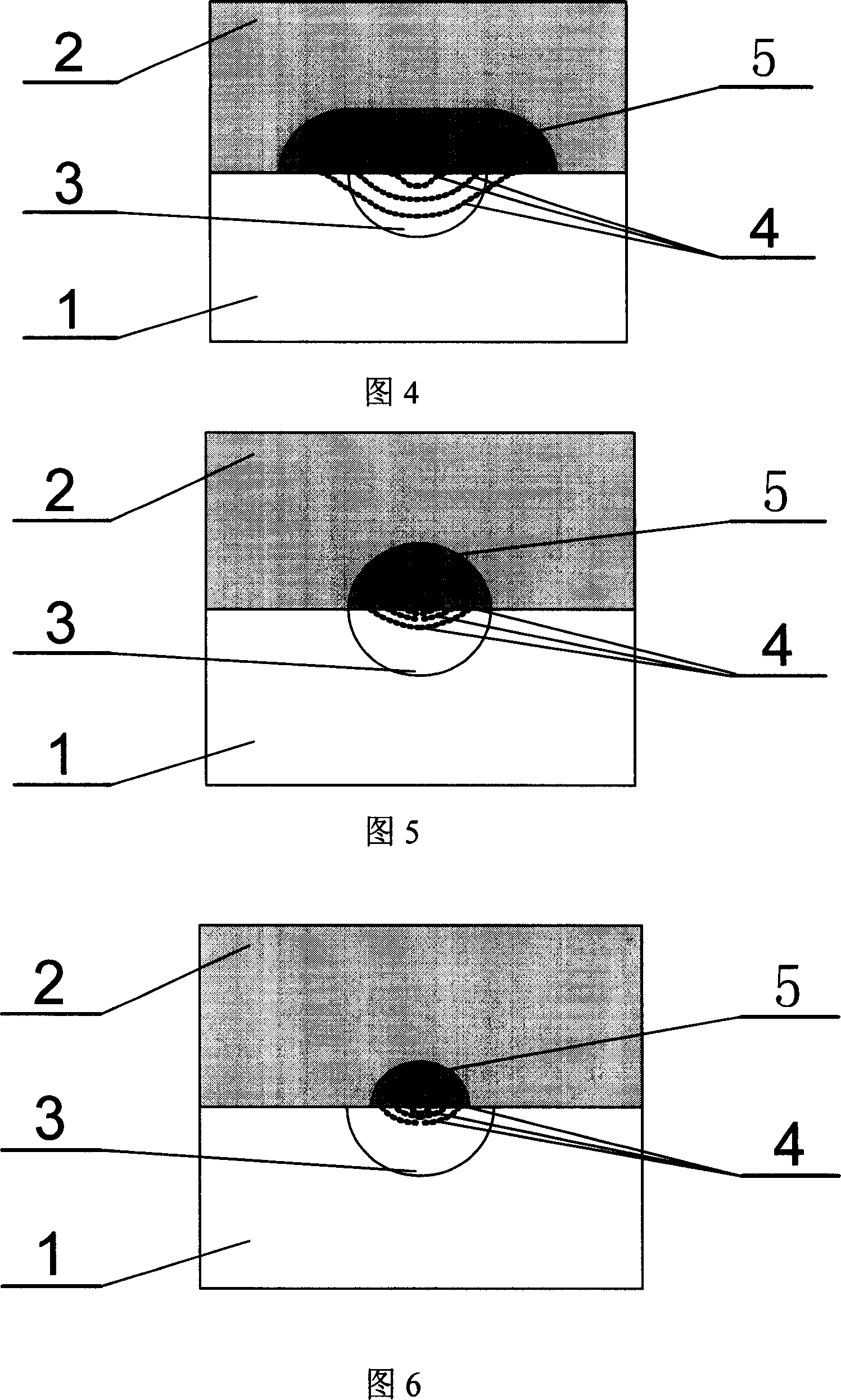

[0045] Embodiment 3: Composite optical waveguide structure see Figure 5 and Figure 6, the main process steps

[0046] The glass substrate 1 is made of silicate optical glass material, and the functional glass substrate 2 is made of phosphate glass doped with rare earth. The main manufacturing steps of the glass-glass composite optical waveguide structure:

[0047] (A) Preparation of light guide region 3 on glass substrate 1

[0048] ·Using microfabrication technology to fabricate strip-shaped optical waveguide masks on glass substrates to obtain ion-exchange windows with a width of the order of microns;

[0049] ·Molten salt ion exchange process is used to make strip optical waveguide, and the ion exchange temperature is 300-400°C;

[0050] • Annealing of optical waveguides.

[0051](B) Preparation of light confinement region 3 on functional glass substrate 2

[0052] ·Using microfabrication technology to fabricate strip-shaped optical waveguide masks on glass substrates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com