Vertical semi-continuous light alloy ingot casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

A synergistic, light alloy technology, applied in the field of light alloy casting, can solve the problems of light alloy large-size ingot casting difficulties, difficulty in meeting deformation production, cracks and looseness, etc., achieve significant size effect of structure solidification, and improve internal metallurgy Quality and surface quality, effect of grain coarseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1AZ31

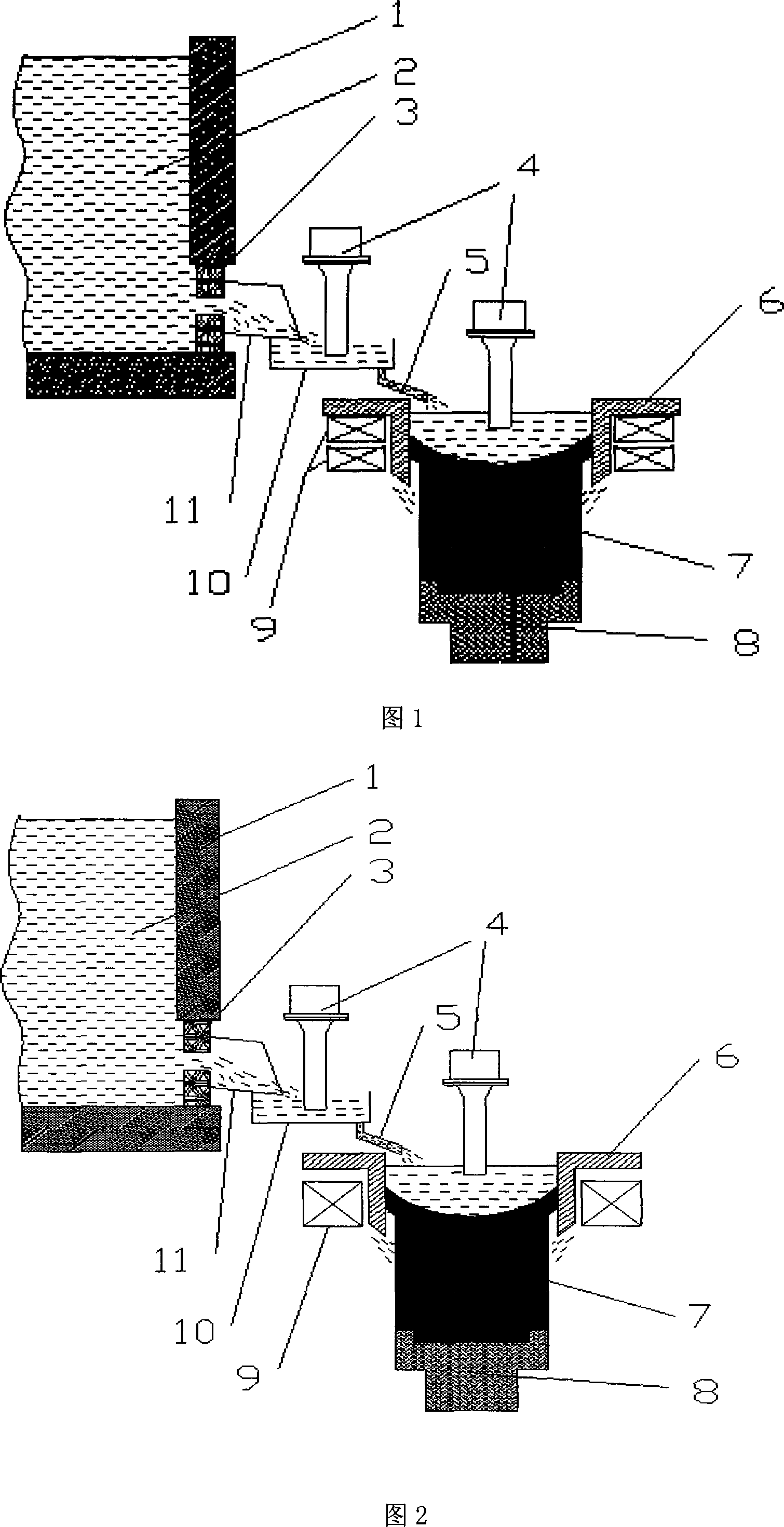

[0024] Embodiment 1 AZ31 magnesium alloy Φ200mm billet vertical semi-continuous casting

[0025] AZ31 magnesium alloy is smelted according to the ratio, and 20ppmBe is added to achieve flame retardancy; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is not treated with ultrasonic in the tundish, and power ultrasonic is applied in the crystallizer The synergy of the field and the low-frequency electromagnetic oscillating field.

[0026] The casting process conditions are: the casting speed is 100mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 6W / cm 2 ; The melt temperature in the tundish is 690°C; the AC frequency is 30Hz, the intensity is 4000AT; the DC intensity is 4000AT.

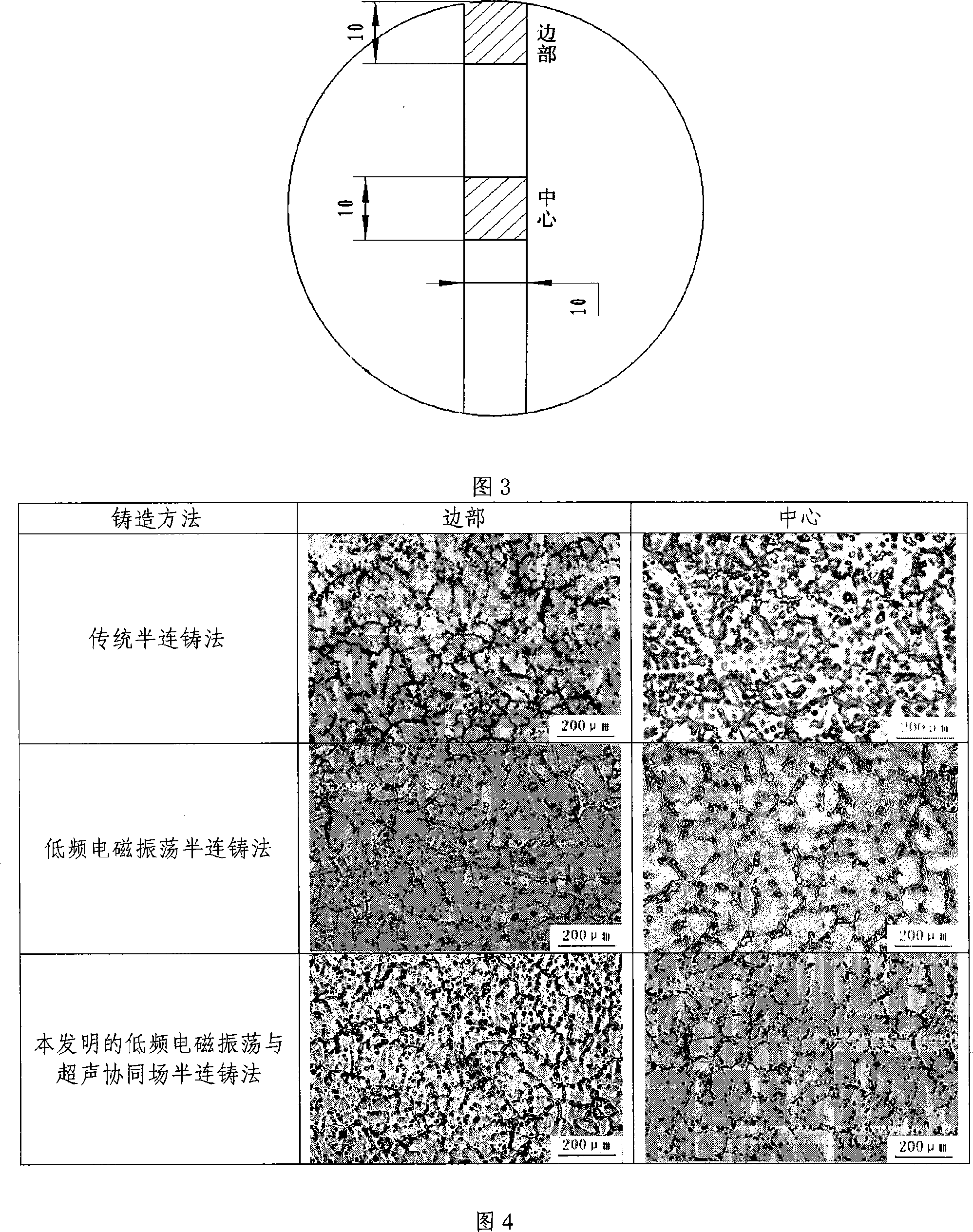

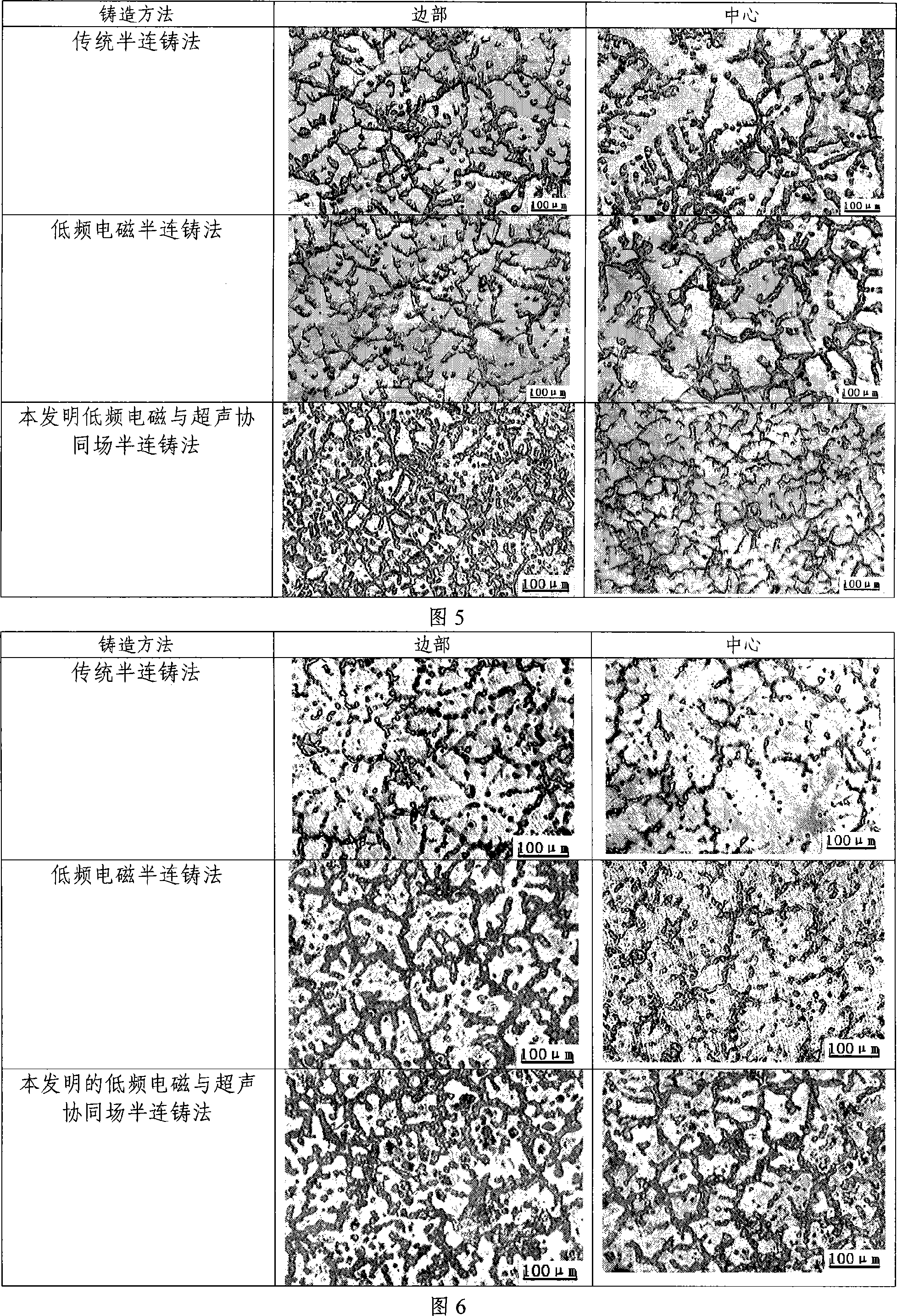

[0027] Fig. 4 is a comparison of microstructures of AZ31 magnesium alloy Φ200mm ingots obtained by traditional vertical semi-continuous c...

Embodiment 2

[0029] Example 2: Vertical semi-continuous casting of AZ80 magnesium alloy Φ300mm billet

[0030] AZ80 magnesium alloy is smelted according to the ratio, and 10ppmBe is added to achieve flame retardancy; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is not treated with ultrasonic in the tundish, and power ultrasonic is applied in the crystallizer The synergy of the field and the low frequency electromagnetic field.

[0031] The casting process conditions are: the casting speed is 90mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 5W / cm 2 ; The melt temperature in the tundish is 670°C; the AC frequency is 30Hz, and the intensity is 6000AT.

[0032] Fig. 5 is a comparison of microstructures of AZ80 magnesium alloy Φ300mm ingots obtained by traditional semi-continuous casting, low-frequency electromagnetic vertica...

Embodiment 3

[0034] Example 3: Vertical semi-continuous casting of MA2-1 magnesium alloy Φ300mm billet

[0035] Smelt MA2-1 (Russian grade, equivalent to AZ41) magnesium alloy according to the ratio, and add 20ppm Be to achieve flame retardancy; the inner sleeve of the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is in the middle bag There is no ultrasonic pretreatment, and a synergistic field of power ultrasonic and low-frequency electromagnetic is applied in the crystallizer.

[0036] The casting process conditions are: the casting speed is 100mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 10W / cm 2 ; The melt temperature in the tundish is 680°C; the AC frequency is 25Hz, and the intensity is 6000AT.

[0037] Fig. 6 is a comparison of microstructures of MA2-1 magnesium alloy Φ300mm ingots obtained by traditional semi-contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com