Directional coagulation aid block as well as ingot furnace provided with same

A technology for coagulation-assisting and ingot casting furnaces, which is applied in self-solidification, crystal growth, single crystal growth, etc., and can solve problems such as unbalanced heat dissipation at the center of directional coagulation-assisting heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

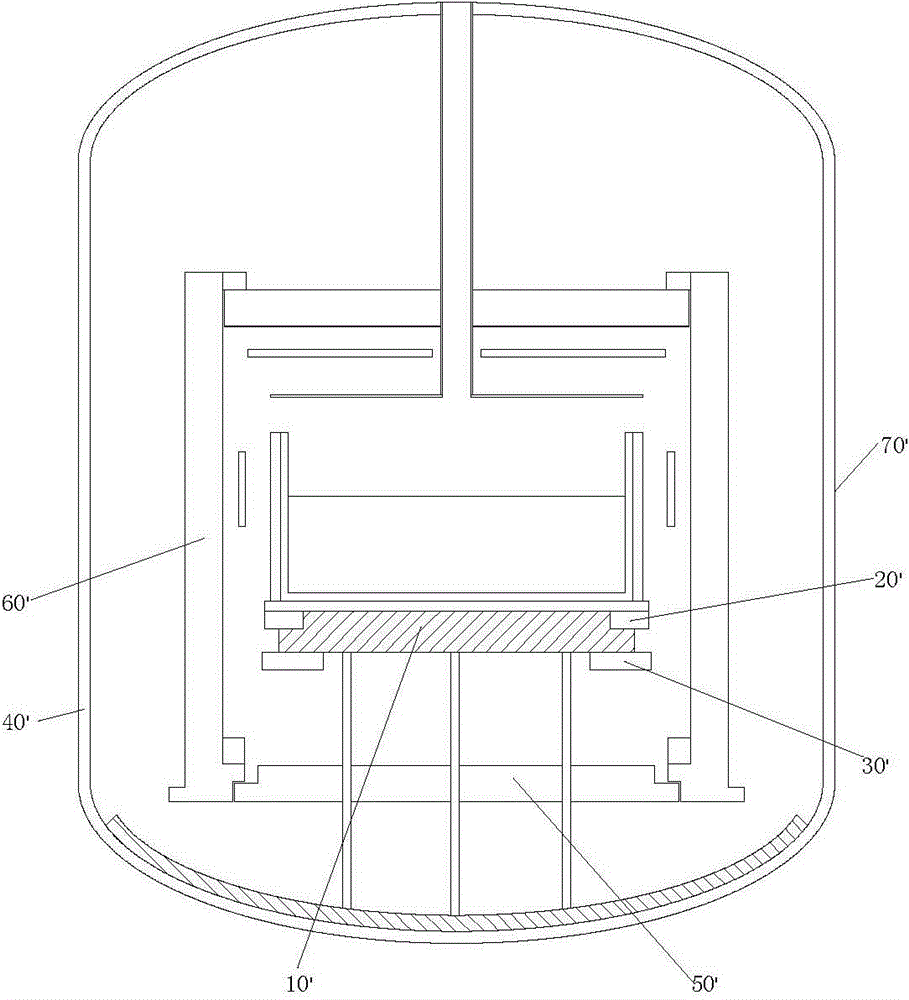

[0026] Figure 5 The direction of the arrow shown in indicates the direction of heat dissipation.

[0027] like image 3 As shown, according to the embodiment of the present invention, the directional clot-assisting body 10 includes a clot-assisting body 10 whose overall thickness is different, and the middle thickness of the clot-assisting body 10 is larger than the peripheral thickness. The thickness of the clot-assisting body 10 gradually decreases from the center to the periphery.

[0028] When polysilicon grows in the ingot furnace, heat conduction is mainly carried out by the coagulation-assisting body. Since the shape of the coagulation-assisting body 10 is changed, the overall thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com